The benefits of 3D printing are now widely recognized across a diverse range of industries. In recent years, the aerospace sector has been exploring 3D printing techniques to design and develop innovative solutions that help advance the industry and take it into a new era.

Image Credit: MIT

Image Credit: MIT

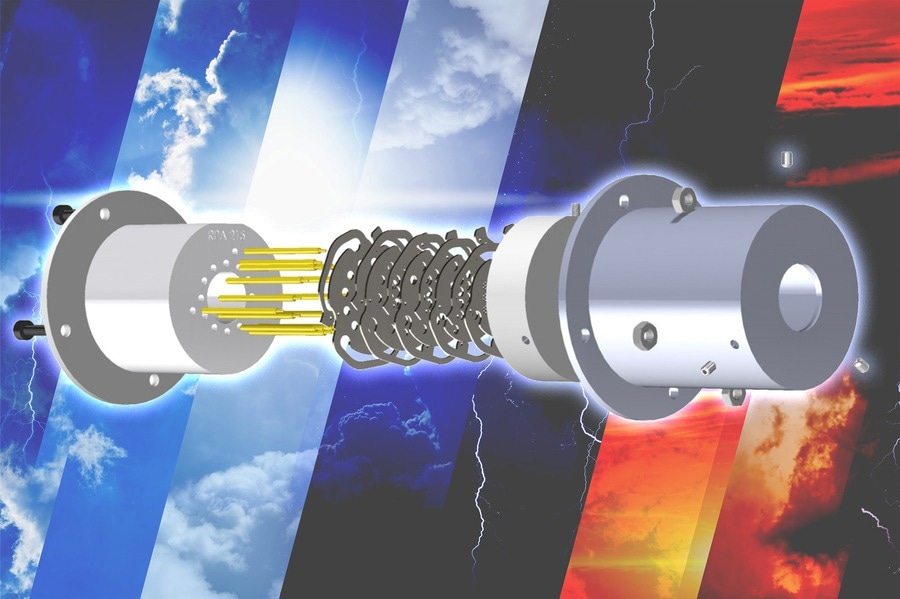

One such advance comes from a group of researchers at MIT who have successfully demonstrated the ability to digitally fabricate plasma sensors for use on spacecraft and satellites to determine the ion energy distribution and chemical composition in the atmosphere.

Known as retarding potential analyzers (RPAs), these plasma sensors help scientists predict weather patterns and could even be used to help monitor the climate and study climate change.

Currently, state-of-the-art plasma sensors are typically manufactured in a cleanroom, yet the MIT team found that the digitally manufactured 3D printed sensors matched the performance of conventional plasma sensors. The research was presented in a paper recently published in the journal Additive Manufacturing.

Additive manufacturing can make a big difference in the future of space hardware. Some people think that when you 3D-print something, you have to concede less performance. But we’ve shown that is not always the case. Sometimes there is nothing to trade off.

Luis Fernando Velásquez-García, Principal Scientist, Microsystems Technology Laboratories, MIT

Low-Cost RPAs

RPAs have a well-established history when it comes to space-based applications. First used in 1959, the sensors are able to detect the energy in charged particles (ions) present in the plasma that floats in the Earth’s upper atmosphere.

Fabrication techniques in a cleanroom typically involve intricate processes and the use of ceramic powders and lasers, which can cause inconsistencies and often requires weeks of finetuning, making it an expensive process all-in-all.

However, the team at MIT was able to successfully manufacture 3D-printed RPA sensors in just a matter of days at a fraction of the price.

The innovative 3D printed sensors were just as versatile as conventional RPAs, meaning that they are ideal for CubeSat (a class of research spacecraft called nanosatellites) applications. These small, lightweight satellites are relatively inexpensive compared to other spacecraft and are predominantly used for communication or environmental monitoring.

When you make this sensor in the cleanroom, you don’t have the same degree of freedom to define materials and structures and how they interact together. What made this possible is the latest developments in additive manufacturing.

Luis Fernando Velásquez-García, Principal Scientist, Microsystems Technology Laboratories, MIT

Vitrolite: The Key to RPA Success

When it comes to the successful and effective functioning of RPAs, the structure that houses the meshes of the sensor is integral. The housing should be able to endure extreme and sudden changes in temperature as well as provide the appropriate levels of electric insulation.

Velásquez-García and his colleagues made use of a material called Vitrolite, which is a printable, glass-ceramic material that is suitable for use in additive manufacturing processes.

Vitrolite is extremely durable and has the capacity to resist temperatures up to 800 ℃ without deteriorating, whereas traditional materials used in RPAs usually start to degrade around the 400 ℃ mark.

Using vat-polymerization, a long-established additive manufacturing process that uses polymers or resins, the 3D structure is built one layer at a time by immersing it repeatedly into a vat Vitrolite. Each layer is then cured using UV light, and as each layer is only 100 microns thick (about the width of a human hair), this process facilitates the fabrication of complex shapes ideal for use in CubeSat applications.

As the entire process was relatively cost-effective, the team was able to test four different prototypes, which demonstrated different performance capabilities in low-Earth orbit. One sensor was effective at detecting cold, dense plasmas, which usually require specialist sensors.

If you want to innovate, you need to be able to fail and afford the risk. Additive manufacturing is a very different way to make space hardware. I can make space hardware and if it fails, it doesn’t matter because I can make a new version very quickly and inexpensively, and really iterate on the design. It is an ideal sandbox for researchers.

Luis Fernando Velásquez-García, Principal Scientist, Microsystems Technology Laboratories, MIT

In the future, the research team hopes to investigate using the plasma sensors in combination with artificial intelligence for specific use cases while also reducing the sensors’ size, thickness, and mass while preserving structural integrity.

References and Further Reading

Izquierdo-Reyes, J., Bigelow, Z., Lubinsky, N. and Velásquez-García, L., (2022) Compact Retarding Potential Analyzers Enabled by Glass-Ceramic Vat Polymerization for CubeSat and Laboratory Plasma Diagnostics. Additive Manufacturing, [online] p.103034. Available at: https://www.sciencedirect.com/science/article/pii/S2214860422004262

Zewe, A., (2022) Researchers 3D print sensors for satellites. [online] MIT News | Massachusetts Institute of Technology. Available at: https://news.mit.edu/2022/rpa-sensors-satellites-3d-print-0727

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.