Being able to directly incorporate sensors into a structure offers a series of unique opportunities, such as the capacity to construct sensing structures with complex geometries and optimize sensor placement.

Image Credit: MIT

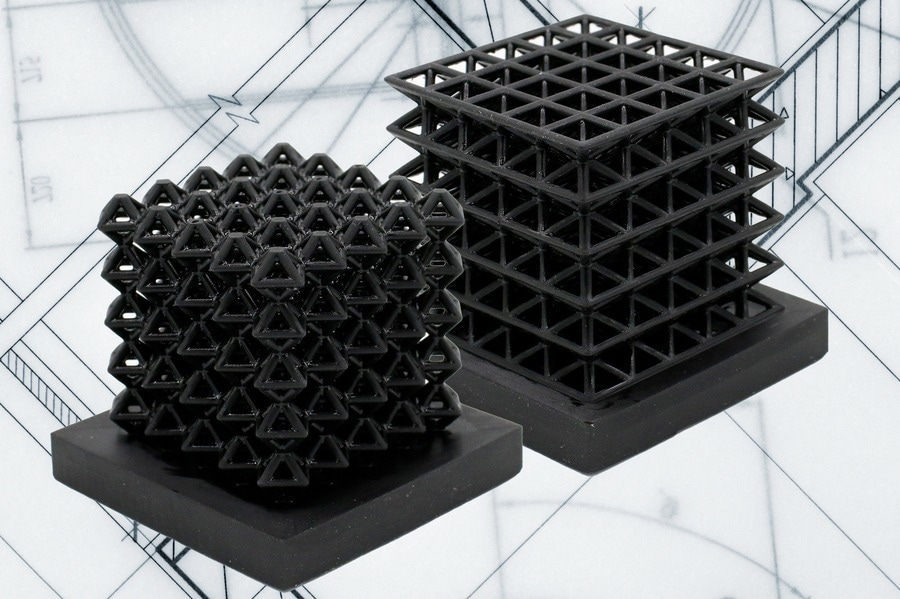

MIT researchers have demonstrated the capacity to do just this after developing a technique that facilitates the 3D printing of sensorized structures with “tunable” mechanical properties.

Published in the journal Science Advances, the team says that their efforts have paved the way for creating sensing structures from a single material using 3D printing techniques. With the capacity to embed sensors in architected materials, a technique that could be applied to soft robotics unlocks the potential to create flexible robots with the ability to comprehend their own movement.

The idea with this work is that we can take any material that can be 3D-printed and have a simple way to route channels throughout it so we can get sensorization with structure. And if you use really complex materials, then you can have motion, perception, and structure all in one.

Lillian Chin, Graduate Student, MIT Computer Science and Artificial Intelligence Laboratory (CSAIL)

Extending the Sensing of Motion

By focusing on architected materials, specifically those in a latticed arrangement, the team was able to see how tuning different mechanical properties made the material more or less stiff. Typically, integrating sensors into complex patterns and 3D structures can prove difficult, meaning sensors are placed on the exterior of the structure, which offers a limited overview of the motion of the material.

Yet, when the sensors are integrated into the object’s structure, the researchers can gain much deeper insights into how the material behaves, thus extending motion sensing capabilities. In order to achieve this, researchers utilized a 3D printing technique to directly insert air-filled channels into the lattice’s structure.

When movement or pressure is applied to the structure, the air-filled channels bend out of shape, and this deformation changes the volume of air inside the lattice. By measuring these changes and fluctuations in pressure using a commercially available pressure sensor, the team was able to gather information on how these changes were taking effect.

Digital Light 3D Printing for Integrated Sensors

To create the complex lattice geometries, the team used digital light 3D printing (DLP), a method that prints 3D structures from a liquid resin that is hardened when exposed to blue light during the printing process. The MIT team ensured that no excess resin was formed on the lattice structures by using an intricate cleaning process with air and a vacuum.

Importantly, we only use one material to 3D print our sensorized structures. We bypass the limitations of other multimaterial 3D printing and fabrication methods that are typically considered for patterning similar materials.

Ryan Truby, Assistant Professor, Northwestern University

While DLP is an innovative way to print 3D structures, the researchers are focused on the possibilities created by sensorized materials as these unique adaptive systems can change the way robots interact with the world around them.

HSA Robots

The team was then able to print a soft robot with integrated sensors using this method – the class of materials produced here are known as handed shearing auxetics or HSAs. These materials are suitable for soft robotics due to their range and flexibility of movement.

By printing a HSA robot with the sensors incorporated into the structure, the team was able to easily track and monitor various ranges of motion, including twisting, stretching, and bending. The data they acquired from these tests was then fed into a neural network which demonstrated the capacity to predict the HSA robot’s motion.

Sensorizing soft robots with continuous skin-like sensors has been an open challenge in the field. This new method provides accurate proprioceptive capabilities for soft robots and opens the door for exploring the world through touch.

Daniela Rus, the Andrew and Erna Viterbi Professor of Electrical Engineering and Computer Science and director of CSAIL

While the team was considering the viability of this technique in soft robotic applications, it could also be transferred to fabricate wearable smart devices that directly transmit feedback on performance and how humans interact within a particular environment, whether that be for athletic performance or health benefits.

The researchers are excited by the future opportunities this work represents as well as seeking new applications for which this technique can be applied while using machine learning to stretch the limits of what is possible in soft robotics.

References and Further Reading

Zewe, A., (2022) New programmable materials can sense their own movements. [online] MIT News | Massachusetts Institute of Technology. Available at: https://news.mit.edu/2022/materials-sense-movements-0810

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.