Asynt introduce the LightSyn Lighthouse – a new photochemical reactor system in their LightSyn range, developed in response to customer demand for higher reaction yields, ease of use, high operational safety, and competitive pricing.

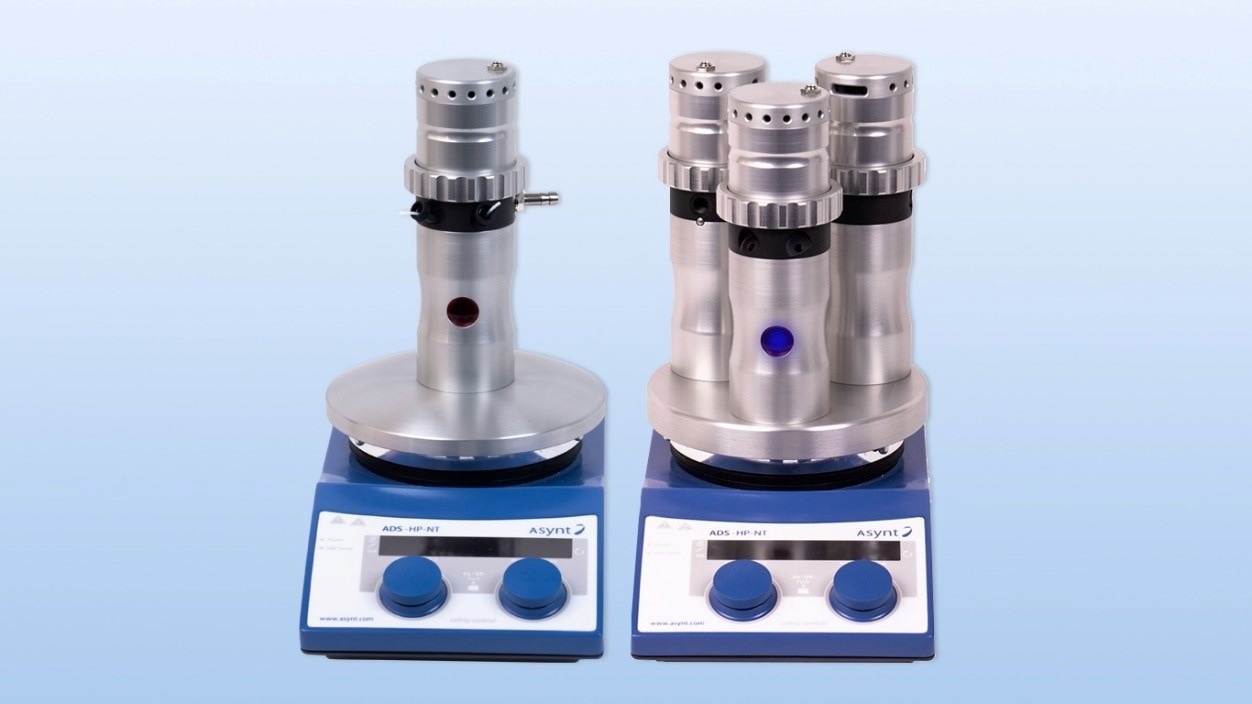

Single position and 3-position LightSyn Lighthouse photoreactor. Image Credit: Asynt

The LightSyn Lighthouse uses new technology to channel light through a quartz rod directly into the reaction medium, maximizing power intensity while keeping photon flux even throughout. Using this system, the amount of photons lost over distance is significantly reduced in comparison to that of a more typical photoreactor, therefore maximizing the light’s interaction with the sample. The result is faster chemistry and higher reaction yields.

Designed to be a useful tool for any lab looking to branch out into larger-scale benchtop photochemistry, the LightSyn Lighthouse is simple to set up and to use, with built-in safety features that eliminate risk of UV light exposure. Easily adapted to suit different sized tubes/vials, and round bottom flasks, the LightSyn Lighthouse is an effective and versatile system for scaling your experiments.

Image Credit: Asynt

Initially available in single or up to 3 position configurations, this benchtop photochemical reactor provides heating & agitation via any magnetic hotplate stirrer and is suitable for temperatures from ambient to +80 ⁰C (or down to -30⁰C with an optional cooling ring – the temperature achieved depends upon the circulator used). In addition to inert atmosphere control there are also integral inlet and outlet ports which allow system customization for a variety of applications including gas reactions/bubbling, programmed reaction management, sample addition or removal, and potentially flow chemistry setups using multiple LightSyn Lighthouse units.

Asynt | LightSyn Lighthouse photoreactor system

Video Credit: Asynt

For further information on the LightSyn Lighthouse please visit https://www.asynt.com/product/lightsyn-lighthouse/ or contact Asynt at +44-1638-781709 / [email protected].