AMETEK Land, the world’s leading manufacturer of non-contact temperature measurement solutions, helps boiler operators achieve highly accurate gas temperature measurements with the upgraded CDB combustion pyrometer.

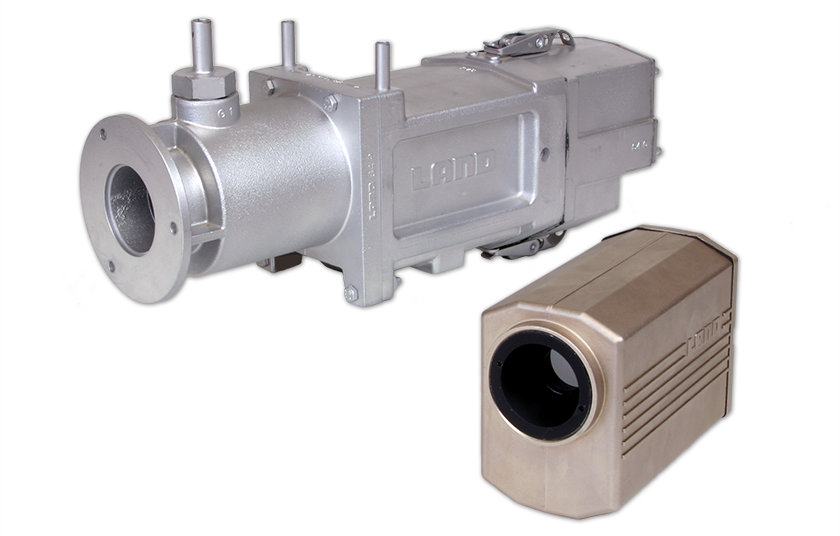

AMETEK Land’s CDB accurately measures gas temperature measurements in boilers. Image Credit: AMETEK Land

AMETEK Land’s CDB accurately measures gas temperature measurements in boilers. Image Credit: AMETEK Land

Measuring furnace exit-gas temperature (FEGT) is difficult because boiler conditions are inhospitable - the heat combined with corrosive gases and a high particulate concentration means taking temperatures can be dangerous, inefficient and unreliable.

Non-contact pyrometers such as AMETEK Land’s CDB pyrometer are ideal for this sort of application, providing true gas temperature measurements efficiently in a proven design. Improving boiler control leads to improved efficiency, reduced maintenance and increased safety for operators.

This System 4 pyrometer provides operators with essential information for boiler control including FEGT. Using a special infrared wavelength that is emitted by hot carbon dioxide (CO2) allows the CDB to see through the cold gases outside the furnace and measure the average temperature along its line of sight within the region of interest. The CDB pyrometer also measures gas temperatures at the boiler exit, where it passes to the air preheater, and in municipal waste incinerators where sufficiently high furnace temperature and long enough residence time are required to ensure complete burnup of the waste materials.

It is installed on the boiler using a permanent mount via a flange adaptor. Air purge protects the optics from hot, corrosive combustion gases.

Derek Stuart, Global Product Manager - Power said: “The CDB combines AMETEK Land’s expertise in temperature measurement and spectroscopy to make a difficult but essential measurement in a combustion process. Accurate measurements of FEGT allow boiler operators to optimize combustion conditions whilst maximizing boiler lifetime.”

For further information about non-contact temperature measurement solutions for boiler and incinerator applications from AMETEK Land, go to: www.ametek-land.com.