North Carolina State University scientists have created a stretchable strain sensor that showcases an unparalleled combination of range and sensitivity, enabling it to identify even minute changes in strain with a greater range of motion than earlier technologies. The scientists developed new health monitoring and human-machine interface devices to illustrate the sensor’s usefulness.

Image Credit: Shuang Wu.

Strain is the amount a material deforms from its initial length. For instance, if a rubber band was stretched to twice its original length, the strain would be 100%.

And measuring strain is useful in many applications, such as devices that measure blood pressure and technologies that track physical movement.

Yong Zhu, Study Corresponding Author and Andrew A. Adams Distinguished Professor, Mechanical and Aerospace Engineering, North Carolina State University

Zhu adds, “But to date there’s been a trade-off. Strain sensors that are sensitive—capable of detecting small deformations—cannot be stretched very far. On the other hand, sensors that can be stretched to greater lengths are typically not very sensitive. The new sensor we’ve developed is both sensitive and capable of withstanding significant deformation.”

An additional feature is that the sensor is highly robust even when over-strained, meaning it is unlikely to break when the applied strain accidently exceeds the sensing range.

Yong Zhu, Study Corresponding Author and Andrew A. Adams Distinguished Professor, Mechanical and Aerospace Engineering, North Carolina State University

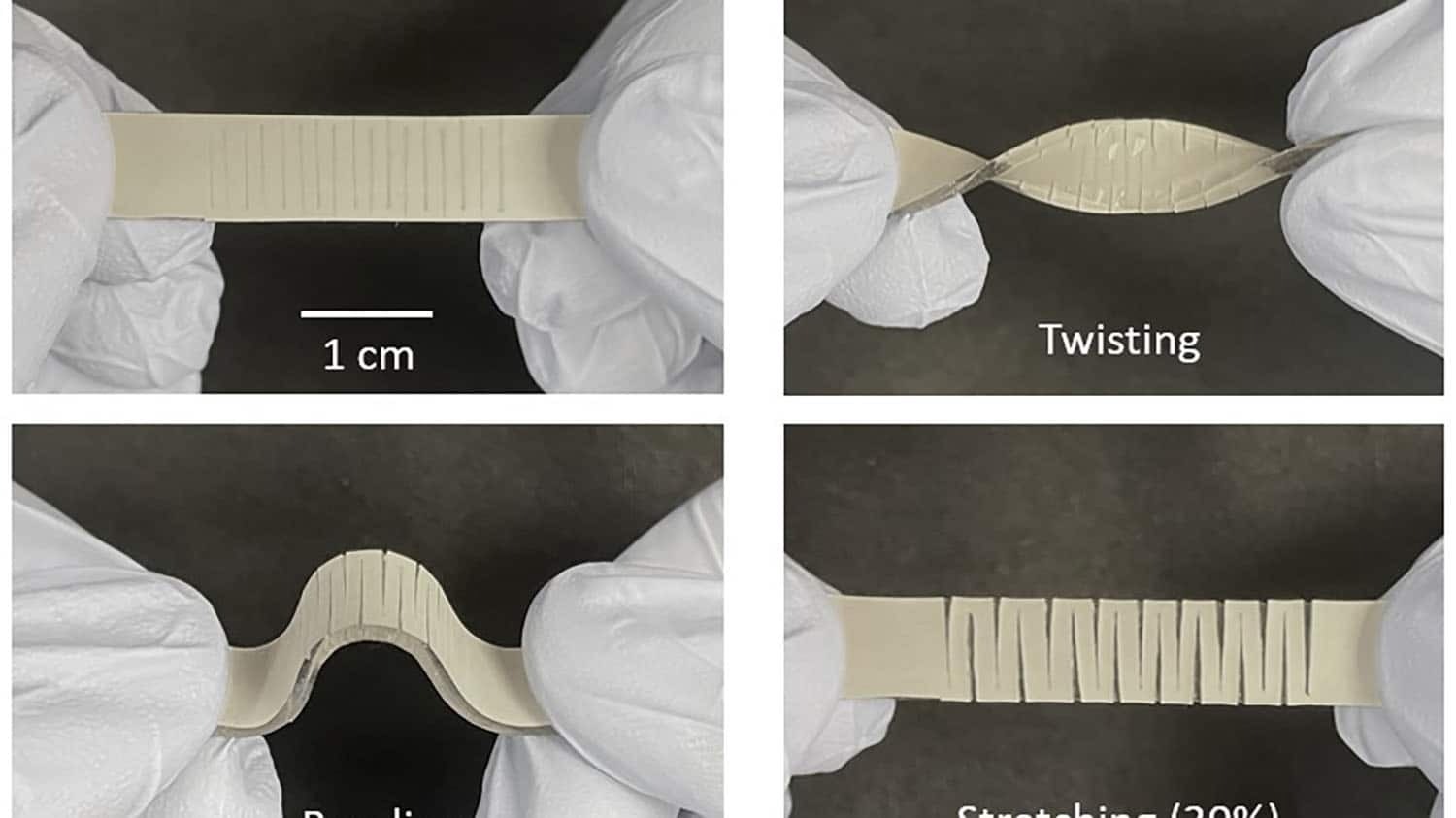

A silver nanowire network incorporated in an elastic polymer forms the basis of the new sensor. The polymer has a pattern of parallel incisions of uniform depth that alternate from either side of the material: one from the left, one from the right, one from the left, and so on.

This feature—the patterned cuts—is what enables a greater range of deformation without sacrificing sensitivity.

Shuang Wu, Study First Author and PhD Graduate, North Carolina State University

Strain is measured by the sensor by assessing variations in the electrical resistance. Resistance increases as the material stretch. The cuts in the sensor's surface are perpendicular to the direction in which it is stretched. This accomplishes two things. First, the incisions enable the sensor to deform significantly.

Since the surface cuts pull open, forming a zigzag pattern, the material can withstand significant deformation without breaking. Next, when the cuts pull open, the electrical signal is forced to travel longer, up and down the zigzag.

Zhu details, “To demonstrate the sensitivity of the new sensors, we used them to create new wearable blood pressure devices. And to demonstrate how far the sensors can be deformed, we created a wearable device for monitoring motion in a person’s back, which has utility for physical therapy.”

“We have also demonstrated a human-machine interface. Specifically, we used the sensor to create a three-dimensional touch controller that can be used to control a video game,” added Wu.

Zhu concludes, “The sensor can be easily incorporated into existing wearable materials such as fabrics and athletic tapes, convenient for practical applications. And all of this is just scratching the surface. We think there will be a range of additional applications as we continue working with this technology.”

The study was published in the journal ACS Applied Materials & Interfaces. Katherine Moody, a Ph.D. student, and Abhiroop Kollipara, a former undergraduate at NC State co-authored the study.

The research was funded by the National Science Foundation, under grant number 2122841; the National Institutes of Health, under grant number R01HD108473; and the U.S. Department of Defense, under grant number W81XWH-21-1-0185.

Journal Reference:

Wu, et al. (2022) Highly Sensitive, Stretchable, and Robust Strain Sensor Based on Crack Propagation and Opening. ACS Applied Materials & Interfaces. doi.org/10.1021/acsami.2c16741.