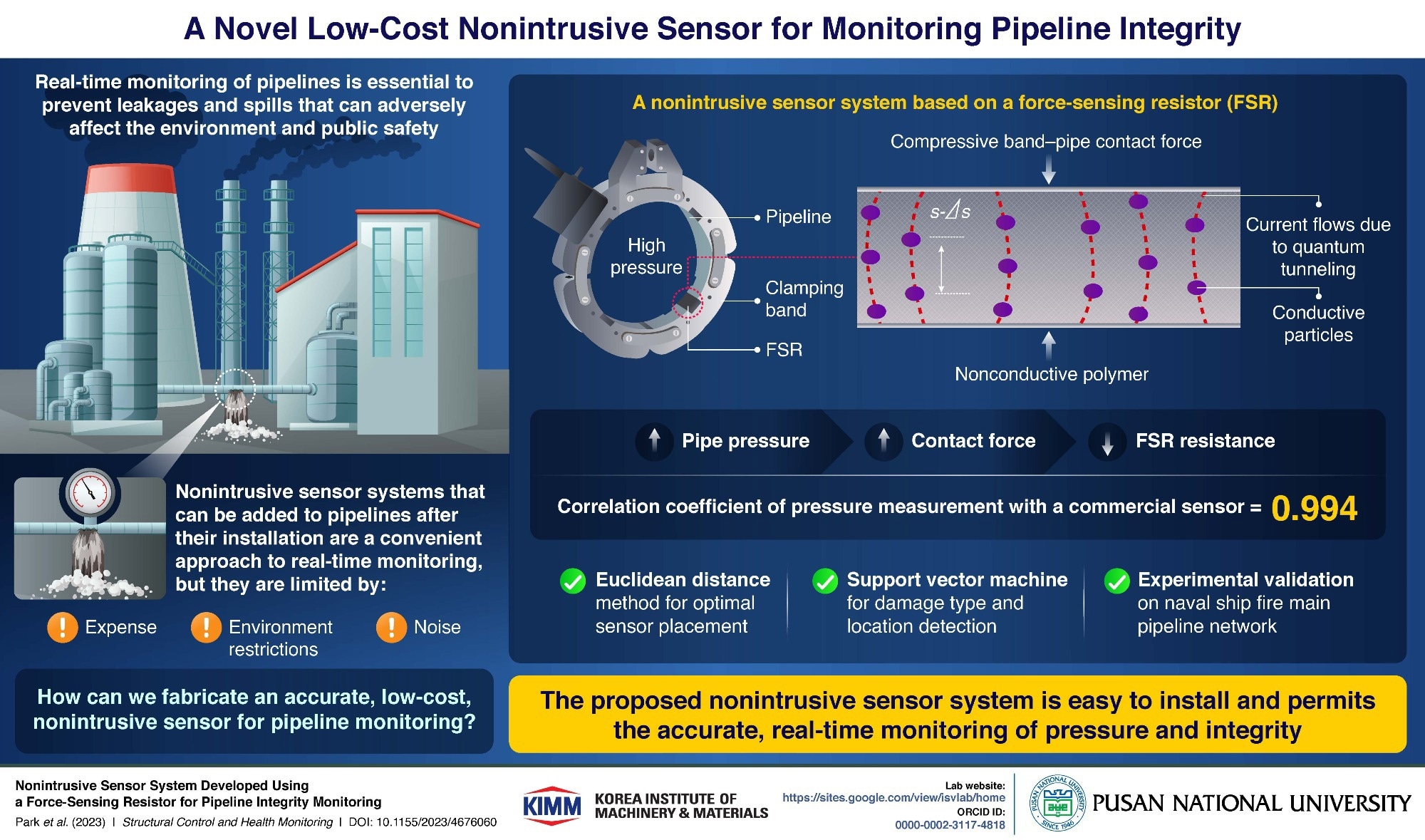

Pipelines, lifelines of the oil and gas industry, can rupture unexpectedly and cause undesirable leaks. Normally, the integrity of pipelines is monitored in real-time using intrusive and non-intrusive sensor systems. While the former need to be pre-installed, the latter offer more flexibility but are limited by cost and environmental noise. Recently, researchers from Korea have proposed a low-cost non-intrusive sensor system for accurate pipeline damage detection.

Researchers from Pusan National University have proposed a low-cost non-intrusive sensor system which employs a force-sensing resistor, the Euclidean distance method, and a support vector machine learning algorithm to optimally detect pipeline damage and monitor pipeline integrity. Image Credit: Yun-ho Shin from Pusan National University

Researchers from Pusan National University have proposed a low-cost non-intrusive sensor system which employs a force-sensing resistor, the Euclidean distance method, and a support vector machine learning algorithm to optimally detect pipeline damage and monitor pipeline integrity. Image Credit: Yun-ho Shin from Pusan National University

Unexpected pipeline failures can lead to leakages that pollute the environment and compromise public safety, thereby underscoring the importance of accurate, real-time pipeline monitoring. Pipelines on naval ships that are a part of fire-extinguishing and cooling systems are especially prone to damage due to frequent projectile launches and collisions.

There are two kinds of sensors for this purpose—intrusive and non-intrusive. Intrusive sensors are highly accurate sensors that measure pressure or mass flow must be pre-installed during the construction of the pipeline. Non-intrusive sensors, on the other hand, use light and sound-based measurement systems. They can be installed after a pipeline is constructed, thereby offering more flexibility. However, non-intrusive sensors are expensive are affected by environmental conditions and noise.

To overcome these limitations, a group of researchers led by Assistant Professor Yun-ho Shin of the Department of Naval Architecture and Ocean Engineering at Pusan National University, has proposed a novel non-intrusive sensor system based on a low-cost, force-sensing resistor (FSR). The research was conducted jointly with the Korea Institute of Machinery and Materials (KIMM) and was made published online in the Structural Control and Health Monitoring journal on 7 February 2023.

The sensor consists of a stiff clamping band with an FSR that contains conductive particles in a non-conductive polymer. “When the pressure inside a pipe increases, the contact force between the pipe and clamping band also increases. That, in turn, compresses the FSR. As a result, the conductive particles come closer to each other, and current starts flowing in the non-conductive polymer due to quantum tunneling. This brings down the FSR resistance. Hence, the sensor can indirectly measure pipe pressure and detect changes in it,” explains Prof. Shin. The researchers found that the novel sensor's measurements showed a 99.4% correlation with a commercial, intrusive sensor, emphasizing its accuracy.

The researchers then utilized the Euclidean distance method to determine where the sensors must be optimally placed in a pipeline network. Based on its results, they installed two sensors on a naval ship-like fire main pipeline system. Their data was fed to support vector machine—a machine learning-based classification algorithm—which allowed them to detect the type and location of damages in the system rapidly and accurately.

“The FSR-based sensors can be applied to any pipeline system in industries with a high risk of pipe failure, including nuclear power plants and naval ships. They will also reduce required manual work by automating pipe integrity monitoring,” concludes Prof. Shin.

The novel, low-cost, FSR-based non-intrusive sensor system paves the way toward more robust pipeline safety, thereby displaying the potential to protect human health, as well as environmental health.