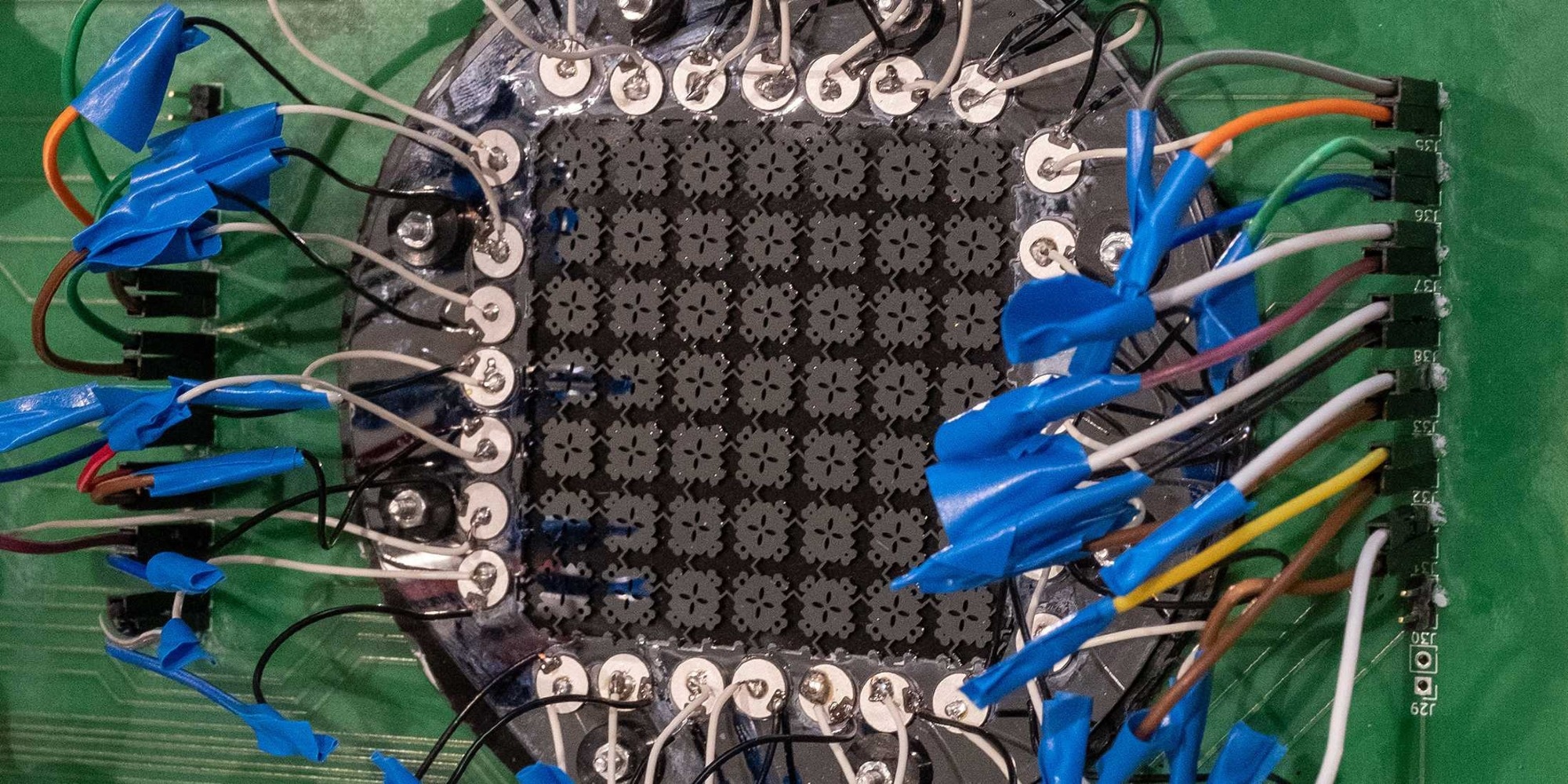

The prototype of the sound sensor is relatively large. Image Credit: Astrid Robertsson/ETH Zurich

Researchers under the direction of Marc Serra-Garcia and Johan Robertsson, a professor of geophysics at ETH, have created a novel kind of mechanical sensor that could potentially provide a solution. The concept has already been published in the journal Advanced Functional Materials, and its inventors have already filed for a patent on their creation.

The sensor only vibrates in response to sound waves that are released when a certain word is pronounced, tone is produced, or noise is made. Then, with enough energy, a little electrical pulse is produced, turning on electronic equipment that has been turned off.

A patent has already been issued for the prototype that the researchers created in Robertsson’s lab at the Switzerland Innovation Park Zurich in Dübendorf. It is able to discriminate between the spoken terms “three” and “four.”

The word “four” vibrates the sensor more than the word “three” does because the latter has less sound energy that resonates with the sensor. Accordingly, the word “four” can toggle on a gadget or start other procedures. “Three” would result in nothing happening.

The sensor’s most recent versions should be able to discriminate between up to twelve distinct words, including common machine instructions like “on,” “off,” “up,” and “down.” The latest versions are around the size of a thumbnail and far smaller than the original, which was approximately the size of a palm. The researchers are working to further reduce their size.

Metamaterial Without Problematic Substances

The sensor is an example of a “metamaterial,” meaning that its unique features come from its structure rather than the material it is made of.

Our sensor consists purely of silicone and contains neither toxic heavy metals nor any rare earths, as conventional electronic sensors do.

Marc Serra-Garcia, Track Group Leader, AMOLF

The sensor is made up of hundreds of identical or similarly designed plates joined by small bars. These connected bars behave like springs. The researchers employed computer modeling and algorithms to create the unique architecture of these microstructured plates and figure out how to connect them. The springs decide whether or not a certain sound source causes the sensor to move.

Monitoring Infrastructure

These battery-free sensors have potential use in construction or seismic monitoring. For instance, they can tell when a structure cracks with the appropriate sound or wave energy.

Battery-free sensors are also being considered for the purpose of keeping an eye on abandoned oil wells. Leaks in boreholes can allow gas to escape, creating a distinctive hissing sound. A mechanical sensor like this one might identify this hissing and sound a warning without continuously using power, which would make it significantly less expensive and maintenance-intensive.

Sensor for Medical Implants

Additionally, Serra-Garcia sees uses for medical devices like cochlear implants. The signal processing in this deaf prosthesis requires a continuous battery-powered power source. Large battery packs cannot fit behind the ear, where their power supply is placed.

This implies that users of these devices need to change the batteries every 12 hours. The innovative sensors may also be utilized to continuously assess ocular pressure.

Serra-Garcia added, “There is not enough space in the eye for a sensor with a battery. There is a great deal of interest in zero-energy sensors in industry, too.”

His current workplace is AMOLF, a public research center in the Netherlands, where he and his colleagues are improving the mechanical sensors. He was formerly employed at ETH. By 2027, they want to introduce a working prototype.

He concluded, “If we haven’t managed to attract anyone’s interest by then, we might found our own start-up.”

Journal Reference

Dubček, T., et. al. (2024) In-Sensor Passive Speech Classification with Phononic Metamaterials. Advanced Functional Materials. doi:10.1002/adfm.202311877