DELO Industrial Adhesives, a high-tech adhesives manufacturer based in Germany, has developed a new medical-grade adhesive, DELO MONOPOX MG3727, as it continues to grow within the medical electronics industry. Based on a long-proven consumer electronics adhesive featuring low temperature curing and drop resistance, this adhesive expands upon its capabilities with non-cytotoxicity, thus meeting the standards (DIN EN ISO 10993-5) necessary to classify it as a medical-grade adhesive.

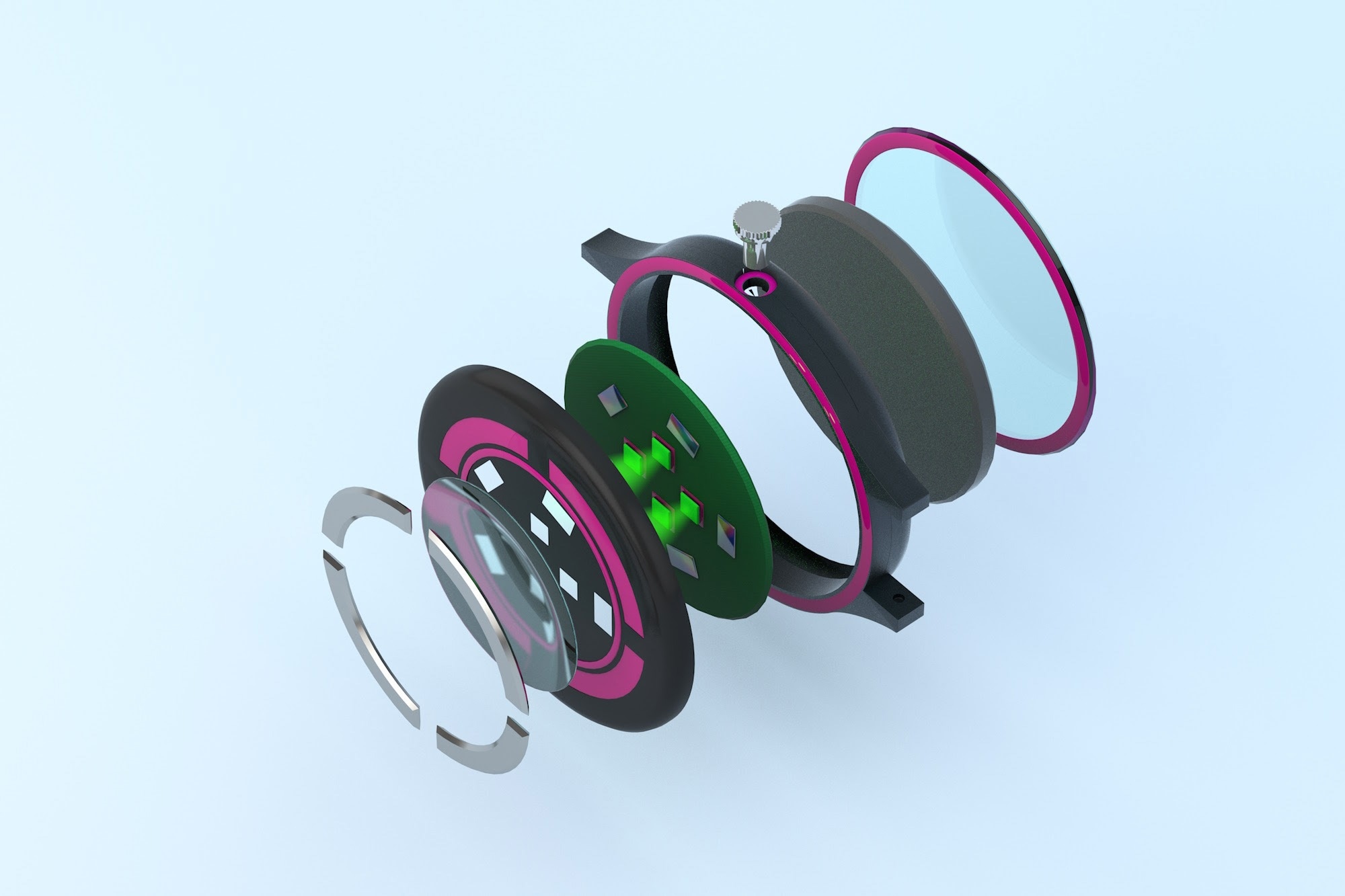

Exploded view of biosensor electrode with adhesive application regions highlighted in magenta. Image Credit: DELO

Exploded view of biosensor electrode with adhesive application regions highlighted in magenta. Image Credit: DELO

DELO MONOPOX MG3727 is tailored ideally for use in the assembly of biosensors, including ECG/EKG electrodes. As stainless steel is often central to the construction of such equipment, DELO ensured that the new adhesive performs well with this substrate material, testing at a compression shear strength of 11 MPa.

This one-component, solvent-free and humidity-resistant adhesive features a low Young’s modulus of 160 MPa, making it resistant to cracking under sudden impact, such as if a sensor falls to the ground. A low glass transition temperature of -52 °C helps the adhesive retain its properties across the range of temperature at which a sensor may be utilized.

DELO MONOPOX MG3727 takes 10 minutes to fully cure via a low heat of 90 °C, making it optimal for temperature-sensitive substrates. With a viscosity of 30,000 mPa·s, it can be easily applied via needle dispensing for optimal production efficiency. Blue fluorescence allows for increased process control of dispensing accuracy.

“This is just one of many medical-grade materials we have planned,” says Günther Witek, product manager for medical electronics at DELO. "And, more importantly, we will bring our semicon manufacturing, miniaturization, and equipment expertise to market, enabling our customers to produce astonishing new products.”

DELO Industrial Adhesives specializes in advanced adhesives and materials for manufacturing in the automotive, consumer electronics, and semiconductor industries, looking to expand within the field of medical electronics.