Nov 29 2010

Select Master Bond for all your cryogenic adhesive, sealant and coating applications. We offer a wide variety of one and two component epoxy systems and the technical expertise you need. Our products are noted for their durability and reliability. Master Bond provides personalized one to one support and our technical staff can recommend a compound tailor made for your needs.

Our epoxies require either ambient or elevated temperatures to cure. They vary in viscosity, cure speed, flexibility, chemical resistance, electrical properties, color, etc. They offer high physical strength and excellent adhesion to similar and dissimilar substrates. Special grades are electrically conductive, thermally conductive/electrically insulative, optically clear, NASA low outgassing approved and mechanical shock resistant. Additionally, a formulation is available called EP29LPSP which possesses the ability to withstand severe cryogenic shocks.

Some of Our Most Popular Cryogenic Epoxies...

| Product |

Description |

| EP29LPSP |

Very low viscosity, two part, optically clear epoxy system. Withstands exposure to cryogenic shock. High bond strength. NASA approved for low outgassing. Requires minimum 135-150°F for curing. |

| EP21TCHT-1 |

Two part, room temperature curable epoxy system with a paste consistency. Possesses excellent thermal conductivity and meets NASA low outgassing specifications. Has a very low thermal coefficient of expansion. |

| EP37-3FLFAO |

Flowable, room temperature curable epoxy system. Meets NASA low outgassing specifications. Outstanding thermal conductivity. Cures flexible at room temperature. Resists vibration, shock and impact. |

| EP21TDCSLO |

Tough, silver filled, electrically conductive epoxy system. Has very low volume resistivity. Cures at room temperature. Offers high peel and shear strength. Passes ASTM 595 for NASA low outgassing. |

| SUPREME 10HTF |

Rapid curing version of our popular Supreme 10HT one part epoxy system. Requires oven curing at 250-300°F. Excellent physical properties. Ideal for thermal cycling. |

Master Bond Cryogenic Systems are used in a Wide Range of Applications

- To mount sensors used for testing

- Cryocooler

- Pneumatic filter regulator

- Neck tubes-tops of flasks and top piece of cryogenic tanks

- Aerospace vehicles

- Conformal coating of electronic circuitry

- Sealant for use in cryogenic pumps

- In MRI (magnetic resonance imaging) devices

- To attach test samples

- To attach temperature sensors to sample holders

- Vacuum feedthroughs

- Cryosurgery spraying apparatus sealant

- Used to seal tubing in cryosurgical devices

|

- Ceramic epoxy transducer-for use in a sensor to detect the level of liquid cryogen

- Insulate cryogenic lines in regions with limited space

- Adhering thermal insulation to aluminum and cryogenic composites

- Adhere and seal cryogenic piping

- Insulating pipelines to prevent clogging (especially underwater pipelines carrying hot oil)

- Adhering thermal insulators to superconducting magnets

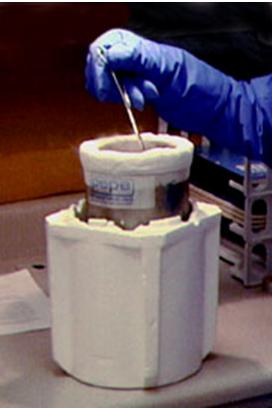

- Storage Dewars (vacuum flasks) for liquid helium, nitrogen, etc.

- Installation of strain gages which see service in cryogenic environments

- Coating/finishing on freezer racks and cabinets used in laboratories and testing facilities of varying industries

- Cryostat-epoxy fiberglass for the inner walls-used to hold a cryogen (usually helium) in a liquid state with minimal evaporation

- Superconducting coils used in SMES systems, electric generators, and to ionize radiation environments.

- Storage tanks for cryogenic fuel to be used in aerospace applications

- Cryomodule-part of a linear particle accelerator which are used for X-ray machines, and other various scientific researches

- For magnetic fusion generators

|

High Reliability & Performance

Master Bond's cryogenic products are designed to offer superior quality and long term durability. They have earned a well deserved reputation for their performance upon exposure to hostile environmental conditions. Select from a wide range of systems conveniently packaged for ease of use. These compounds are available in different viscosities, cure times, chemical resistances, electrical properties, colors, etc. to best meet specific requirements. They are presently employed in applications ranging from design and production to repair, maintenance and field service.

Important Cryogenic System Performance Requirements

Master Bond cryogenic systems are designed to meet specific performance requirements. Among the most important are:

- Chemical Resistance

- Easily Repairable

- Excellent Adhesion

- Dimensional Stability

- High Temperature Resistance

- Impact Resistance

- Flame Resistance

- Low Coefficient of Thermal Expansion

- Low Outgassing

- Low Shrinkage

- Low Stress

- Resistance to Water

|

- Peel Strength

- Durability

- Thermal Cycling

- Shock Resistance

- Thermal Conductivity

- Vibration Resistance

- Dielectric Strength

- Volume Resistivity

- Dielectric Constant

- Electrically Insulative

- Hardness

- Tensile Strength

|

Packaged the Way You Need It

Master Bond offers a wide array of packaging options to speed productivity, minimize waste and save energy including...

- Quantities from grams to gallons

- Cans, bottles and jars

- Cartridges for manual and pneumatic guns

- Premixed and frozen syringes

- Bipaks for field service kits

New Cryogenic Epoxy Adhesive Formulations

| EP51FL – 1 |

Highly Flexible, fast curing epoxy adhesive. High peel strength properties. Cures at room temperature and has a one to one mix ration. Mechanical shock Resistant. |

| EP21TDC – 2 |

Two part, room temperature curing adhesive with high flexibility. Bonds well to a wide variety of substrates. Outstanding thermal and mechanical shock resistance. |

| EP37 – 3FLF |

Superb optical transmission properties. Can withstand rigorous thermal cycling. Low exotherm. Very flexible. Long working life. |

| Supreme 10HTS |

Silver filled, electrically conductive epoxy adhesive. Exceptional peel and shear strength properties. One part, no mix compound. Low volume resistivity. |

Electronic Grade Polymers for Electronic Manufacturing by Master Bond

Master Bond’s line of microelectronic formulations consists of epoxies, silicones, polyurethanes, acrylics and latex solutions. They include electrically insulative, thermally conductive and electrically conductive systems. Both one and two component compounds are available for use. These products are currently employed in applications ranging from heat sinking to glob tops to surface mounting. Many of these compounds have unique properties such as low thermal expansion coefficients, exceptionally high thermal conductivity, low stress, etc. Master Bond is also actively engaged in developing new products to keep pace with the rapid technological advancements in the microelectronic industry ranging from flip-chip technology to advanced die-attach processes.

Master Bond offers specialty systems for computers, telecommunications devices, audio/video devices, avionics and aerospace applications, as well as automotive manufacturing, interactive circuitry and advanced semiconductor equipment.