Dec 29 2010

The research team guided by Dr.MeiyongLiao, a Senior Researcher of Sensor Materials Center, at the Japan-based National Institute for Materials Science has developed innovative suspended structures such as cantilevers and bridges made out of single crystal diamond for nano/micro electromechanical system (NEMS/MEMS).

MEMS Switch

MEMS Switch

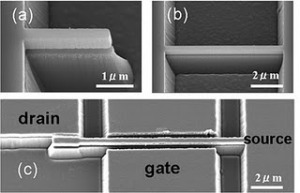

By employing this methodology they were able to produce the initial single crystal diamond NEMS switch for the first time in the world.

In contrast to the prevailing MEMS switches, this diamond NEMS switches exhibit high-performance with great reliability, durability, rapidness, electrical handling potential, etc. The devices can be used as microwave switch for next-version of wire-free transmissions and logic circuit under extreme conditions.This research also provides insight into the structuring of diamond NEMS/MEMS with improved operations, thus advancing different physical,chemical, and mechanical sensing devices.

The discharge current of this new diamond NEMS switch is extremely less with much lower power utility even lower than 10pW (picowatt). The devices offer high recurrence, security and least surface stiction. Diamond NEMS switch shows constant operation at 250°C. The portable cantilever design of Young’s modulus is calculated as 1100GPa, which is nearest to the bulk diamond single crystals value, producing high-speed gigahertz switching functionality.

The suspended single crystal diamond architecture was created by locally producing a graphite sacrificial film in a single diamond crystal substrate employing intense energy ion embedding and also by growing a diamond epilayer using electrical conductivity by means of microwave plasma chemical vapor deposition method (MPCVD) and subsequent elimination of graphite sacrificial layer. The research team has also succeeded in developing NEMS switching devices having a transistor-resembling structure featuring three electrodes.