imec, a company conducting research in nanoelectronics, and Holst Centre, an open-innovation independent research and development centre, have announced the creation of a micromachined vibration energy harvester that provides high output power.

A 489 µW output power was obtained in the Micropower Generation and Storage program and was showcased at the International Electron Devices Meeting (IEDM) 2011.

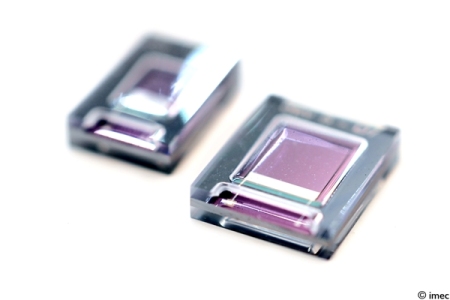

Harvesters with various dimensions. The shiny capacitor stack on top of the beam is visible through the glass package.

Harvesters with various dimensions. The shiny capacitor stack on top of the beam is visible through the glass package.

The micromachined vibration harvester includes a cantilever having a piezoelectric layer that is sandwiched between electrodes to form a capacitor. A mass is fixed to the cantilever’s tip, which converts the macroscopic vibration into a movement in the vertical direction. This creates a strain on the aluminum nitride piezoelectric layer and generates a voltage. A wafer scale vacuum packaging process is employed for packaging the harvesters.

When vibrations match the 1011 Hz resonance vibration of MEMS, the harvester achieves an output power of 489 µW. The harvester can also be used in car tires for harvesting shock-induced energy. This can be used to power built-in sensors such as wireless sensor nodes. At speeds of 70 km/h, a high constant power output of 42 µW can be harvested.

Micromachined vibration harvesters hold the potential for generating power from engines, machines and other appliances that undergo repetitive shocks or vibration. Harvesters facilitate sustainable monitoring. In settings where replacement of battery is not feasible or sustainable these harvesters can provide power for small autonomous sensor nodes. Vehicle tires having built-in sensors for monitoring driving styles, road conditions, tire pressure and integrity is an example of such harvesters.