Tekscan, a developer of thin-film tactile pressure, force sensors and flexible position sensors for OEMs, has introduced the ultra-thin Nip Pressure Measurement System (NPMS).

Nip Pressure Measurement System

Nip Pressure Measurement System

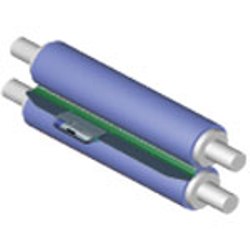

The pressure management tool has been designed to detect misalignment between rollers and for measuring nip pressure between rollers.

The real-time measuring tool accurately measures roller profiles to manage uneven pressure distribution and misalignment issues. It transmits the profile data from an inbuilt wireless unit to a remote laptop/PC located at a distance of 100 m. The added flexibility provided by the lack of wires connecting the NPMS system to the remote laptop/PC enables maintenance operators to use the system throughout the assembly line or the plant to measure roller readings.

The Tekscan NPMS solution identifies issues with roller deformation, crown deficiencies, non-uniform loading, and misaligned rolls. When the NPMS solution is placed in between two contacting rollers, it measures the nip width and pressure data in real-time. As technicians and machine operators continue to adjust the rollers, the real-time pressure data helps them determine how the changes affect the roller strip. The NPMS system saves the measurements which can be easily accessed for predictive and preventative maintenance procedures, to improve product quality and to minimize production delays.

Featuring a 0.004” thick tactile pressure sensor in the self-contained, lightweight and portable unit, the NPMS can accommodate rollers across pulp & paper industries, iron & steel mills, packaging plants, printing machines, plastic & composites, converters and textile plants. The nip pressure measurement system is available in four lengths of 72”, 54”, 36” and 18”.