By Kalwinder KaurMay 24 2012

Davis Instruments newly launched Fluke 805 Vibration Meter boasts an innovative sensor with a novel sensor tip design to reduce the variations in measurement due to contact pressure or device angle.

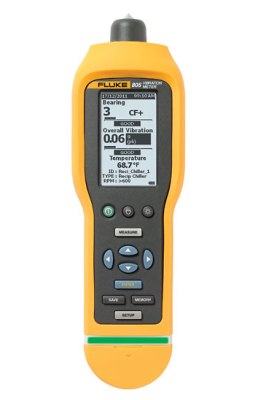

Fluke 805 Vibration Meter

Fluke 805 Vibration Meter

It ensures repeatability, high precision and reliability while testing bearings and overall vibration. Frontline mechanical troubleshooting teams employ this handheld screening meter for more efficient repeatable readings of bearing condition and overall vibration.

The Fluke 805 Vibration Meter is capable of generating reliable and constant data quality at low as well as high frequency ranges. Four-level severity scale detects the seriousness of issues and transmits exportable data through the USB. The incorporated templates enable the trends to be documented in Excel. On-board memory can record up to 3500 measurements.

An extensive array of various machines include overall vibration measurement ranging from 10 Hz to 1000 Hz for velocity, acceleration, and displacement units of measurement. The Crest Factor+ ensures consistent bearing assessment based on direct sensor tip measurements from 4000 to 20,000 Hz. The amount of pressure required for measurements will be notified and alerted by a colored lighting system and on-screen comments. Spot IR Sensor-based non-contact temperature measurement enhances diagnostic capabilities.

Based in Vernon Hills, Illinois, the 1912-established Davis Instruments has been one of the dynamic suppliers of measurement, test, control, and calibration instruments. It serves industries including field services, power and utilities, petrochemicals, construction, and aerospace and electronics production.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.