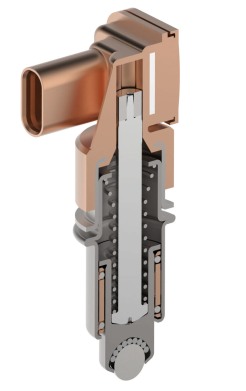

Precision bearing and automotive component manufacturer Schaeffler has developed a new highly integrated sensor system for detecting neutral and reverse gear positions in manual transmission systems. The system is currently available for use in advanced engine stop-start (ESS) systems.

Schaeffler sensor detent

Schaeffler sensor detent

Most first-generation neutral gear detection systems comprise an add-on sensor with a separate magnet fitted to three separate mounting positions. However, the new Schaeffler sensor detent requires no add-on components and is installed in just one mounting position. The highly integrated design of the sensor detent also means that the selector shaft and housing no longer require additional machining for mounting.

The sensor element reliably detects the selected drive position and sends this information to control units incorporated in the vehicle. The sensor detent is characterised by high component functional integration and is the result of continuous development of existing components to include new functions.

New demands

The electrification of engine drive trains for internal combustion engines; new advanced ESS systems; the development of hybrid electric vehicles; and the automation of vehicle systems, are placing new demands on manual transmission systems. Whereas the first generation of ESS systems are still based on traditional components, the next generation of ESS systems will be integrated in the vehicle’s information highway, creating significant potential for improvements in driver comfort and vehicle energy efficiency.

Traditional sensor detents have always been part of Schaeffler’s product range. Schaeffler works closely with automotive OEMs worldwide in developing solutions for customising the gearshift “feel” of manual transmissions to meet the needs of specific vehicle brands and models.

The Schaeffler sensor detent combines an existing detent with a sensor that measures lift. The forced stroke of the detent that occurs during gearshifts is recorded and processed in the gearshift unit using the sensor on the detent. The relevant signal is output to an integrated connector. Depending on vehicle requirements, the sensor can handle pulse width modulation (PWM) or single edge nibble transmission (SENT) protocols and can also output analogue signals. The sensor detent positions the gearshift unit in neutral in all shift gates and simultaneously detects this position, which ensures high accuracy.

By operating in conjunction with the second gearshift detent, the system enables customer-specific demands to be met in terms of gearshift and selection forces, as well as improving gearshift comfort for the driver.

The Schaeffler sensor detent uses a non-contact, wear-free sensor to detect neutral gear position. The sensor detent also detects reverse gear position and outputs the relevant signal, which means the contact reverse light switch and all mechanical interfaces are no longer required. By standardising on the electronics and programmability of the sensor, the sensor detent can be easily adapted to suit the specific requirements of the vehicle.

“The new sensor detent offers a highly integrated solution for detecting neutral and reverse gear for manual transmissions and it creates one of the prerequisites for engine stop-start systems,” comments Stanislav Massini, Director of Advance Development and Mechatronics at the Shift Systems Product Line at Schaeffler. “Its high level of integration means that some components, various mounting elements and some stages of the manufacturing process are no longer required.”

The sensor detent plays an important part in reducing vehicle fuel consumption and engine emissions, while also cutting vehicle weight and costs. The sensor detent is already in volume production at Schaeffler and is currently available for engine stop-start applications.

For more information on Schaeffler’s sensor detent, please call the UK Marketing Department on 0121 313 5870. Alternatively, email [email protected]