Mar 24 2010

The EU project 3Plast research scientists are working on printable piezoelectrical and pyro-electrical large area sensor technologies.

New Printable Sensors Give Hopes of Controlling Gadgets by Just Pointing a Finger

New Printable Sensors Give Hopes of Controlling Gadgets by Just Pointing a Finger

Such printable sensors are likely to emerge as a reality in next few years.

The institutes and organisations involved in the project aim to make temperature and pressure sensors in mass volumes. These sensors could be inexpensively printed onto plastic films and also attached flexibly to a multitude of daily usage objects like electronic equipment. The Fraunhofer Institute for Silicate Research ISC in Würzburg, Germany, is coordinating the activities of this project that has been funded to the tune of €2.2 million.

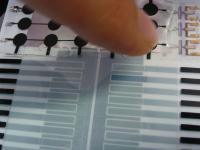

Piezoelectrical and pyroelectrical polymers that constitute these printable sensors can be processed in mass volumes using screen printing, for instance. An organic transistor is combined with the printable sensor for strengthening the sensor signal. According to project head Gerhard Domann, the sensor signal strength is at its maximum where the finger is positioned. A specialty of this sensor is that the organic transistor can also be printed on the sensor.

However, manufacturing of polymer sensors currently poses many hurdles. Very thin insulators have to be used for making these sensors. ISC experts, however, are able to make an insulator that is a mere 100 nm thick. Such sensors have been printed on films already. Presently these research scientists are working to optimize transistors that will amplify rapid pressure and temperature changes.

ISC experts, however, are able to make an insulator that is a mere 100 nm thick. Such sensors have been printed on films already. Presently these research scientists are working to optimize transistors that will amplify rapid pressure and temperature changes.

Domann explained that environment-related information provided to daily objects, such as information on persons approaching, using temperature sensors, it is possible to develop and market new gadgets that will be controlled by a pointing finger. Domann added that the technology may also find applications in robotics and construction and automotive industries. Domann informed that the project will be completed by end January 2011, but it will take several years before it is possible to print sensors on large surfaces.