Mar 20 2015

Konica Minolta, Inc. is going to show, as technology showcase, prototype of metal mesh transparent conductive film by inkjet process and touch panel sensor film under development at the 25th Finetech Japan (April 8-10, Tokyo Big Sight; Booth No. 45-42).

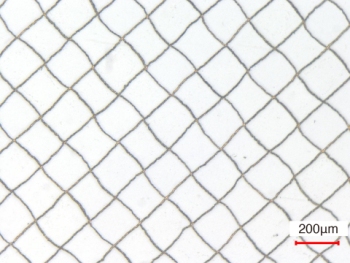

Konica Minolta Metal Mesh Transparent Conductive Film by Inkjet Process (Photo: Business Wire)

Konica Minolta Metal Mesh Transparent Conductive Film by Inkjet Process (Photo: Business Wire)

Transparent conductive film is an important material for touch panels and has traditionally used ITO (Indium Tin Oxide), while research and development on metal mesh transparent conductive film has made progress in recent years. As metal mesh transparent conductive film has potential to substantially reduce resistance and add flexibility, it is expected to bring greater freedom in designing touch panels, including larger size, higher sensitivity or curved shapes.

Konica Minolta made an early technology showcase of inkjet metal mesh transparent conductive film in October 2014 at Display Innovation 2014 in Yokohama, Japan. It has drawn a significant attention for its low-visibility 5-micron fine metal lines, which was believed to be difficult in inkjet printing, the world’s top-class 0.3-ohm/square (minimum) resistance and high durability. These advanced features were based on proprietary technologies of Konica Minolta, a leader in the industrial inkjet head sector.

Utilizing its metal mesh transparent conductive film, Konica Minolta is also developing sensor film for touch panels. Furthermore, the company is working on development of roll-to-roll manufacturing process toward higher productivity for practical use. As inkjet has advantages such as direct printing process and high productivity, Konica Minolta continues driving technology development for practical applications.

After the show, Konica Minolta will be making evaluation samples available on request basis.