Jul 22 2015

Kathryn Wills, of the National Physical Laboratory (NPL) and Coventry University, discusses the role smart textiles have to play in remote healthcare in an article for the Guardian's Healthcare Professionals Network.

Smart textiles

Smart textiles

The ability to remotely monitor patients' conditions as they go about their daily lives could revolutionise healthcare, allowing more patients to live normal lives, reducing hospital administration and freeing up beds. Kathryn believes that new research integrating electronics directly into the fabric of clothing could move us a step closer to this smart technology.

Sensors can provide detailed, real-time information about a patient, alerting medical professionals if there is a warning sign, for example high blood pressure or swelling. But we are yet to see sensors that can pick out minor physiological fluctuations, while integrating into everyday life.

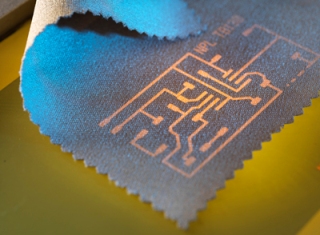

Smart textiles, which allow accurate and reliable electronic sensors to be built into everyday clothing, could be the solution. In the article, Kathryn talks about research she's currently involved in at NPL and Coventry University, printing conductive circuits directly onto the fibres of garments. The technique first deposits silver nanoparticles onto the individual fibres; copper can then be bound to the nanoparticles and used to create a conductive layer. This allows complex circuits to be printed onto clothing, which still perform after stretching and washing.

Kathryn writes: "Circuit printing opens up a myriad of possibilities as it allows a network of sensors to be precisely positioned across the area to be monitored, without being affected by clothes moving on the body."

The technique has been successfully demonstrated on a variety of materials including cotton, polyester and linen. The next step is to further develop the chemical deposition process on other materials, before scaling the process up for commercialisation. With the right interest, Kathryn believes the technology could be employed in the healthcare profession within three to five years.

Kathryn joined NPL as part of a Knowledge Transfer Partnership (KTP) award from Innovate UK, which brought together NPL's Electronics Interconnection Group and Coventry University's Functional Materials Group to work on smart textiles. Their work was recently exhibited at the Royal Society Summer Science Exhibition 2015.