There are multiple ways in which engineers can design coil springs. Some clip the end of the spring "square." This creates a small high-pressure point at the end of the spring, which transfers load eccentrically.

Other designers prefer to bend the last coil to make it perpendicular to the axis or shave the last coil at the pitch angle. This helps spreading the load over a large area.

Pressure distribution can be accurately measured in each of these designs.

Challenge

Determine the pressure distribution between a coil spring and support that enhances longevity, performance and properly balances load.

Solution

I-Scan™ pressure mapping system can measure pressure distribution. The system's sensors intrude minimally and can measure the contact area of the spring by being positioned under the coils. They can also measure the changes that occur in the contact area or the pressure distribution that occurs during the application of various forces.

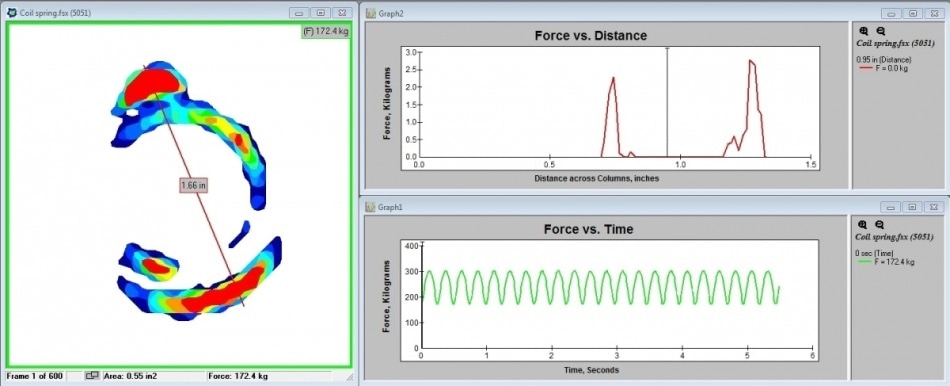

2D and 3D displays of the pressure data are available and can be used in the comparison of coil spring designs during simulated operating conditions. Tekscan offers patented, reusable, thin-film sensors, which are available in different shapes and sizes, and provide accurate contact pressure measurements.

High pressure on the outside of the loaded spring is illustrated by the 2D output of the coil spring. Force vs. distance graph showing higher forces on the outside of the spring. Force vs. time graph showing consistent force over the duration of the test.

Coil Spring Pressure Measurement Applications

- Research, design and development

- Determination of load balance around the coil

- Small and large diameter coil sizes comparison

- Testing the performance

- Life cycle assessment

- Quality assurance

Benefits of Using I-Scan to Design and Test Coil Springs

- Guess work is eliminated by putting real numbers on force, location, contact area, and pressure distribution on the end of the coil

- Helps in the determination of optimum shape, thickness and materials

- Aids in spring wear and linear stability predictions by displaying the contact load distribution as a function of applied force

See how Pressure Mapping Technology can help automobile manufacturers obtain dynamic pressure data to extend the life of vehicle components, like coil springs:

Pressure Mapping in R&D - Evaluating Product Performance

This information has been sourced, reviewed and adapted from materials provided by Tekscan, Inc.

For more information on this source, please visit Tekscan, Inc.