With over 200 pressure sensors to choose from, the versatile I-Scan™ system is a tactile pressure mapping system which is tailor-made for users’ application needs.

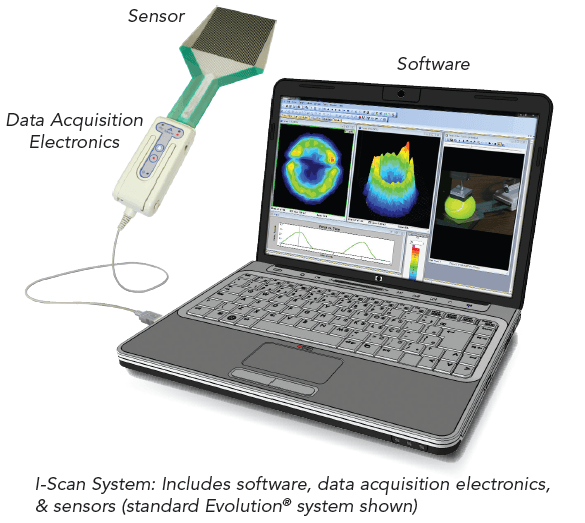

The thin and flexible properties of the I-Scan™ sensor make it a powerful tool that can precisely measure and analyze the pressure between two surfaces. The device includes software, data acquisition (DAQ) electronics and sensors.

The incredibly thin tactile sensor records both force and pressure, offering the smallest interference between the sample objects being investigated while simultaneously achieving the best measurements, with the most accurate interface pressure data.

The results provide crucial information and insight that can be used to improve quality, manufacturing, research and product design.

Advantages of Using the I-Scan™ System

Key information that can be collected using the I-Scan™ system is: total force, pressure distribution, peak pressure, center of force and forces in different areas.

The benefits of using the I-Scan™ system in the following applications are:

Product Design

Using the I-Scan™ system in product design allows for a thorough understanding of surface behavior. Between two components, the verification of forces and peak pressures can be carried out while measuring external forces. Moreover, the system reduces the number of failures and related costs.

Manufacturing

The I-Scan™ system can also be used in manufacturing to increase the reproducibility of the processes, as well as verify calibration machinery and decrease the time it takes to carry out processes. Overall, this system reduces downtime and improves yields.

Quality Control

The I-Scan™ system can identify potential failure modes and can play an important role in the quality control and benchmarking stages of manufacture.

Research

When using the I-Scan™ system for applications in research, scientists are further able to understand the physical characteristics of the objects being investigated and the pressure distribution between two surfaces.

Testimonial

TMMK has been using the I-Scan system for the last two years, resulting in over 3,000 push/pull tests. The I-Scan provides our Safety and Engineering team with an accurate measuring device to record push/pull forces on a majority of our parts. The Tekscan system is easy to use and very dependable and has helped to improve our ergonomic initiative.

- John Whitaker, Assembly Safety Specialist, Toyota Motor Manufacturing, Kentucky

Configurations

To collect pressure information, data acquisition (DAQ) electronics scan each sensor, which contains thousands of sensing points. The data is then instantaneously relayed to the software on a user’s computer, via a USB cable. Tekscan’s sensors can scan at a maximum of 1,600,000 sensing elements in a second.

To provide users with the best possible solution to their application, I-Scan™ has a range of DAQ electronics options. The configurations provided in this document shows users what system options, features, and configurations are available. The devices available are the Evolution, VersaTeck, Wireless, and Datalogger. Below is a table which compares the different devices.

| |

Evolution (Standard USB) |

VersaTek (High Speed USB) |

Wireless (VersaTek Wireless) |

Datalogger (VersaTek Datalogger) |

| DAQ Electronics |

Evolution Handle |

VersaTek Handle, VersaTek Hub |

VersaTeck Handle, Wireless Unit |

VersaTek Handle, Datalogger Unit |

| Maximum Scanning Speed |

100 Hz |

20,000 Hz |

4,600 Hz |

20,000 Hz |

| Cross Handle Scanning |

No |

Up to 8 |

Up to 2 |

Up to 2 |

| Pulse-Per-Frame Synchronization |

No |

In & out |

In & out |

In & out |

| Adjustable Sensitivity |

x 3 to 1/7 of Sensor Pressure Rating |

x 7 to 1/3 of Sensor Pressure Rating |

x 7 to 1/3 of Sensor Pressure Rating |

x 7 to 1/3 of Sensor Pressure Rating |

| Power Source |

USB Port of PC |

100-240 V Power Supply |

Li-Ion Battery: 8 V, 2.4 A or Power Supply: 100-240 V |

Li-Ion Battery: 8 V, 2.4 A or Power Supply: 100-240 V |

| Maximum Handle Cable Length |

5.0 m (16.4 ft.) |

30.48 m (100 ft.) |

30.48 m (100 ft.) |

30.48 m (100 ft.) |

| Maximum Hub Cable Length |

n/a |

5.0 m (16.4 ft.) |

5.0 m (16.4 ft.) |

5.0 m (16.4 ft.) |

| Device |

|

|

|

|

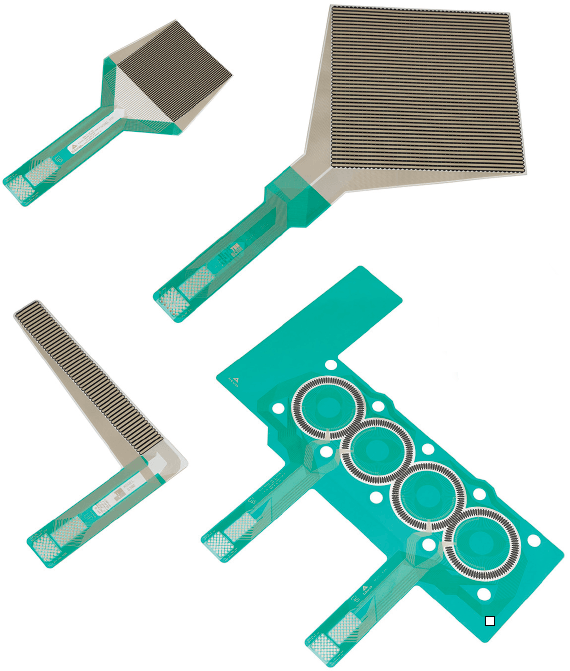

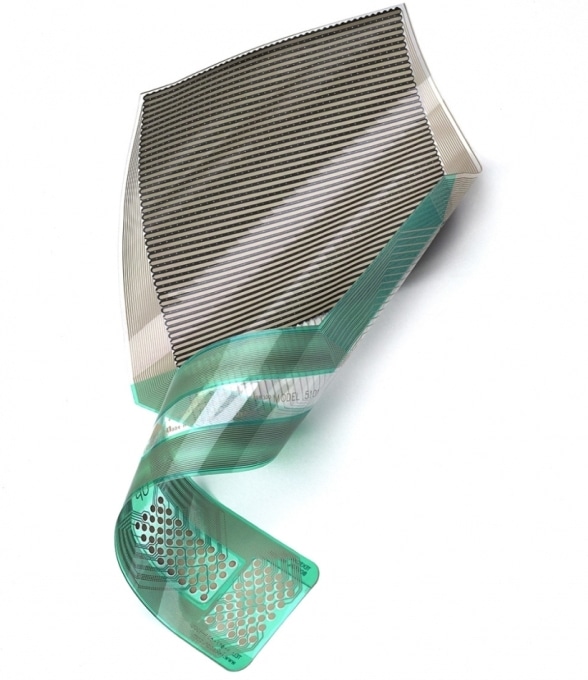

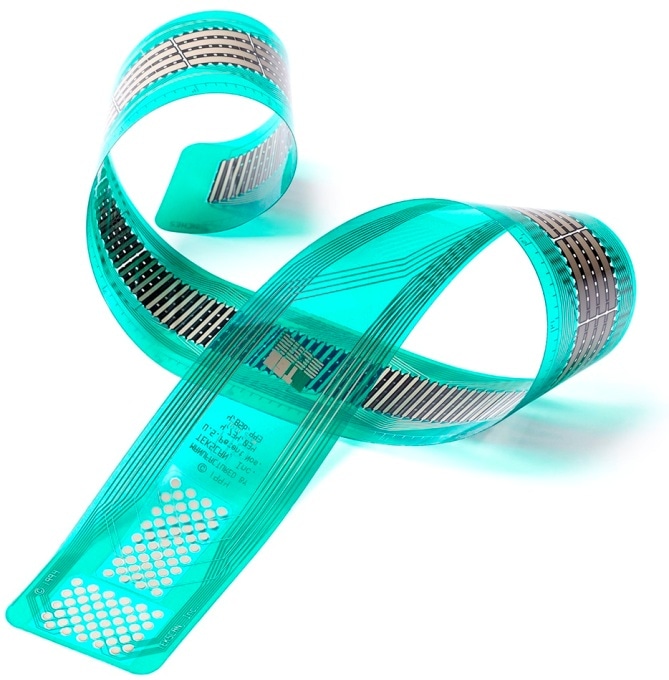

Sensors

TekScan offers more than 200 different thin, flexible film tactile pressure sensors, providing a variety of shapes, sizes, resolution, temperature ratings and pressure ranges (up to 25,000 psi or 1,700 bar).

Through Tekscan’s expansive choice and customizability of sensors, the following properties are available:

| High Spatial Resolution |

Up to 248 sensing elements/cm2 (1,600 sensing elements/in2) Sensing elements with as narrow as 0.6 mm (0.02 in.) spacing |

| Sensing Area |

Ranging from 3 mm x 3 mm (.12 in. x .12 in.) to up to 1,734 mm x 1,768 mm (68 in. x 69 in.) |

| Optional High-Temp Sensors |

Able to withstand up to 200 °C (392 °F) |

Below are a few of the different pressure sensors TekScan has to offer:

Software

Software which accompanies the I-Scan™ provides users with a complete set of tools that enable a higher standard of analysis than other pressure sensing technologies.

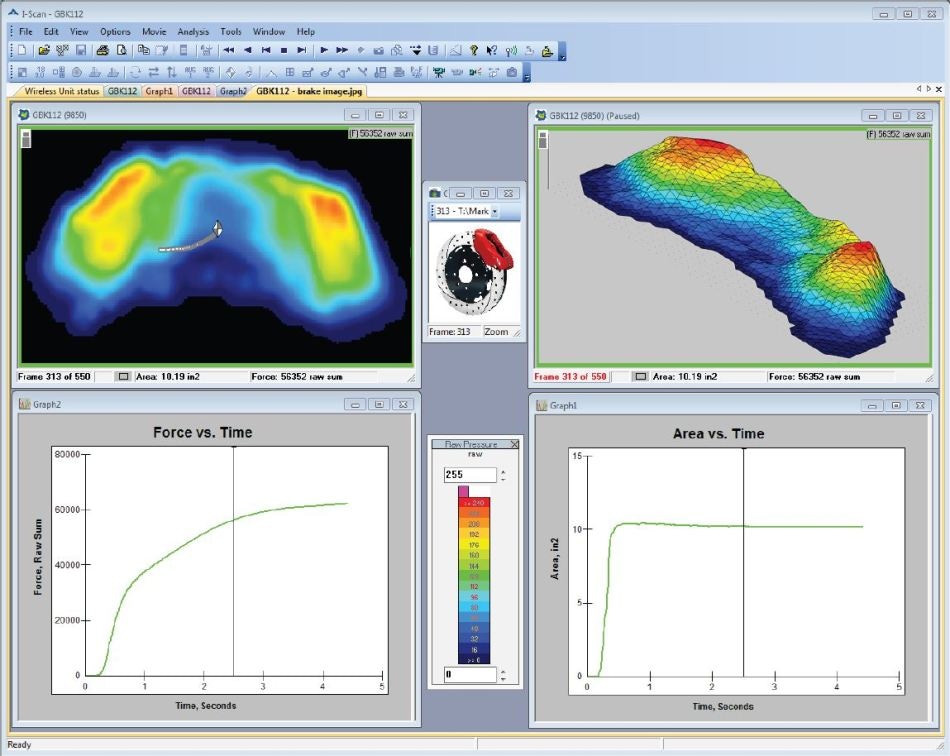

The pressure distribution recorded is displayed in different ways, enhancing data analysis. These images are given in real-time, and the user can play back and save FSX movies. Graphs can also be made using corresponding movie data and can be exported as ASCII files.

Below is the Standard I-Scan software window interface, showing the pressure distribution between a brake pad and rotor.

Standard I-Scan software window displaying the pressure distribution between a brake pad and rotor.

Key Features

- View data as an integrated Microsoft Excel table

- Real-time display of pressure sensor data in 2D & 3D

- Graphing & data analysis (pressure, force, & area)

- Export data to ASCII or AVI files

- View and compare multiple test results simultaneously

- Display peak pressures & center of force