High-precision robotic systems are usually used to perform most of the electronic assembly processes. These systems are tasked to properly move and insert delicate components onto a circuit board. To do so, frequent checks must be performed on the assembly robots in order to detect changes in alignment that can occur as a result of their routine use.

Challenge

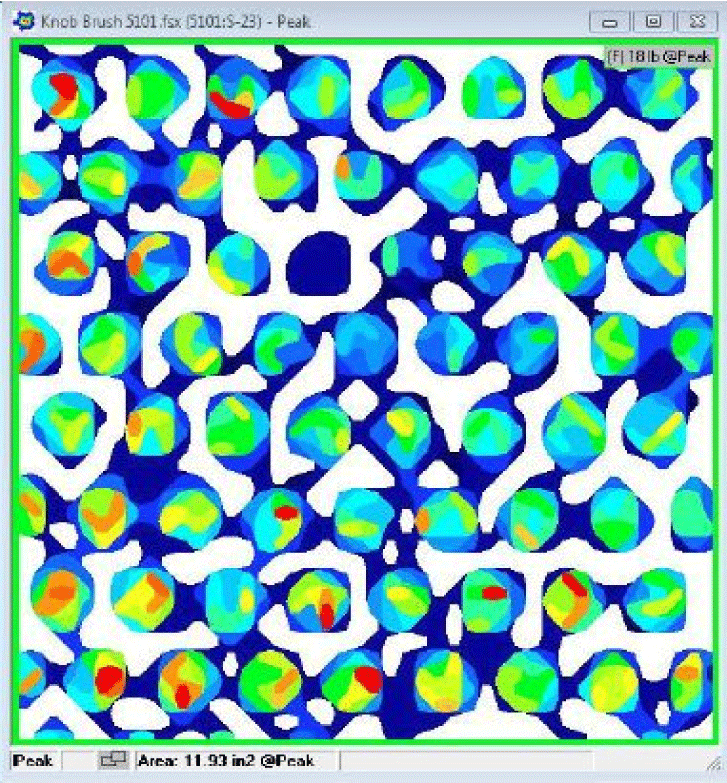

The main challenge is to develop a machine application that is capable of generating clear and verifiable data on the performance of robotic manufacturing systems. This can help capture any changes in pressure or alignment in the production process, which can help reduce the risks of significant, expensive errors.

Solution

Embedding pressure mapping technology into an assembly machine can help verify that all robotic elements are interfacing with the circuit board components correctly. This data can help the operator in taking better control over the operation and confirm that the correct amount of force is applied in every movement.

Integrating high-resolution pressure sensors, customized software and electronics creates a seamless procedure for this delicate process.

Other Similar Applications

- Robotic chip placement

- Heat sinks

- Wafer polishing

- Probe card testing

- Chemical machine polishing (CMP)

Watch this video to learn more about how Pressure Mapping Technology can help validate component press fits or seals:

Pressure Mapping in R&D - Evaluating Component Press Fits & Seals

This information has been sourced, reviewed and adapted from materials provided by Tekscan, Inc.

For more information on this source, please visit Tekscan, Inc.