Image Credit: Mrs_Ya/Shutterstock.com

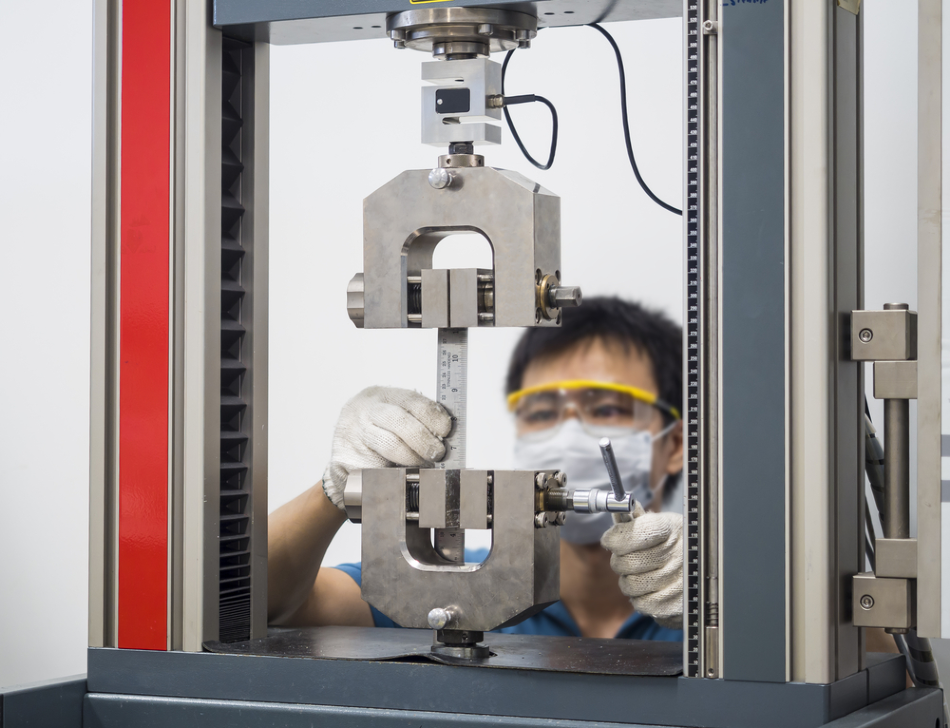

Measuring the impact that pressure has on materials is an essential part of properties testing that allows researchers to fully understand how materials can be used in different applications. Accurate measurement of pressure effects is vital to developing products that are safe and suitable. It also helps scientists to innovate new uses for materials; expanding product capabilities and reducing the time spent in the prototyping phase.

Iowa State Team Innovates New Nanoscale Sensors

This year, a team of researchers at a lab based in Iowa State University published the findings of their latest study outlining how they had established a new method of accurately measuring how high pressures impact materials. The team innovated nanoscale sensors, which their testing revealed to be highly efficient at assessing the stresses and strains that materials go under when subject to high pressures.

Professor and mechanical engineer at Iowa State University, Valery Levitas, who was a co-author of the paper published last week in the journal Science, had already set up a lab at Iowa State that specializes in experimental testing and computational modeling within the space of high-pressure science. The lab was already equipped with the correct hardware for developing such innovation in pressure measurements and was also home to a wealth of expertise from Levitas and his colleagues.

In fact, the lab in Iowa is the only location worldwide where researchers have access to multi-scale computer modeling for the diamond anvil experiments that were key to the current research.

Inserting Sensors into Diamonds to Measure Pressure Effects

The paper describes how the US team developed nanoscale sensors, known as nitrogen-vacancy color centers, which they inserted into diamonds. The reason diamonds were chosen as a carrier for the array of sensors is because the material is famously strong and capable of exerting large amounts of pressure on other materials without breaking or deforming. The study saw the team using the sensor filled diamonds to apply pressure to tiny samples of materials.

The sensor-embedded diamonds were used to generate measurements, images, and calculations pertaining to six classifications of materials stress. The system they established also was proven capable of measuring how changes in pressure influence the material’s magnetism. The results of the study showed the nanoscale sensor technology to be more efficient than alternative methods of measuring pressure effects on materials.

What the Iowa team has achieved is providing a solution that has long troubled the field of high-pressure science. That is, that the simultaneous measurement of all six types of materials stress has been, up until this point, unattainable. However, by twisting the materials following applications of pressure, the team was able to significantly reduce the phase transformation pressure, leading to new phases of matter being identified. This advancement will likely have applications in areas of science outside of the niche of high-pressure science.

The Impact of the New Sensor Technology

Advancements in materials testing have the potential to impact on numerous areas of science. Technology, engineering, construction, electronics, medical, automotive, chemistry, mechanics, geology, planetary science, and many more fields have the potential to be positively impacted by innovations in materials testing. Being able to better understand how materials behave and change under pressure is key to understanding their suitability. This information helps scientists determine which materials are best for a certain purpose, enabling innovation to be made in disparate areas of science. The current study has opened up new avenues of research, with scientists now equipped to accurately analyze material impact at very high pressures.

References and Further Reading

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.