Speed is everything in fire protection, and this does not just apply to firefighting once a fire has broken out. If a developing fire is detected quickly, there is a greater chance of minimizing damage via rapid intervention.

Infrared measurement technology makes the early detection of fires possible. IRIS GmbH – a company that regularly implements these sorts of systems – does this using an infrared camera from Optris.

Bodies with a temperature higher than absolute zero (-273.15 °C) emit what is known as characteristic radiation at their surface - electromagnetic radiation which is proportional to the body’s temperature. Some of this radiation is infrared radiation, and this can be utilized to measure temperature.

Contemporary sensor technology allows cameras to be built which, thanks to their high thermal sensitivity of 40 mK, allow the detection of even very slight differences in temperature. While the human eye would see an image of the body, these cameras instead produce a thermal image, allowing the temperature to be determined for each point in the image.

A false-color view of thermal images like these can be helpful in many applications – from electrical system maintenance to industrial process control, where faults can be identified through high temperatures emanating from contacts.

Early Fire Detection Using Infrared Cameras

IRIS GmbH has developed a specialized, successful system for early fire detection. The company has sites in Wülfrath and Lüneburg, and has been actively working with industrial measurement technology for 28 years.

IRIS GmbH offers a wide-ranging portfolio of technical measurement products from different manufacturers, with their focus areas including non-contact temperature measurement which uses infrared measurement technology. Optris GmbH has worked with IRIS GmbH for many years in this area, with IRIS selling Optris’ products since 2003.

Infrared measurement technology offers a number of advantages to fire protection systems.

Using this method, fires can be detected very early by using a temperature threshold which still lies below the ignition temperature.

Kirsten Köhn, Managing Director, IRIS

Using this method, it is possible to detect a potential fire even before it starts, through the detection of increasing temperature. IRIS’ IRIScan FS system uses this approach to function, and the system is built using an industrial infrared camera from Optris with a proven track record.

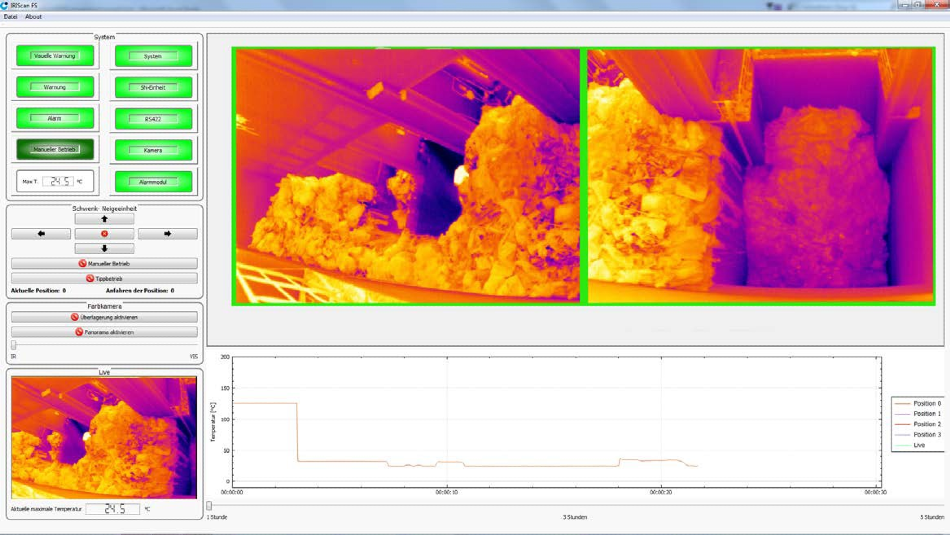

The system is supplied with the IRISvisual software, a package designed specifically to evaluate captured thermal images before localizing a thermal hazard source in real-time.

The IRIScan FS system is able to detect fires at an early stage using infrared measurement technology.

The highest temperature is determined for every part of the image, and should this temperature exceed the predefined threshold, the system will trigger an alarm or warning.

Our system works with multi-stage adjustable warning and alarm thresholds. Depending on the application, a first warning is triggered even at a temperature of 70 or 80 degrees Celsius.

Kirsten Köhn, Managing Director, IRIS

Users can rapidly identify the corresponding position on the infrared image, and in most instances, this allows the fire to be prevented in plenty of time. Waste bunkers provided some of the first applications for IRIS’ early fire detection system. “You could say that was the start of our business in this area,” recalls Köhn.

Other common application areas of the system have included storage areas in the tire, paper and textile industries, biomass plants, and recycling plants. IRIS has also successfully installed an IRIScan FS to monitor a tunnel system.

Overall, the system is suitable for use in many sectors where traditional fire detection methods are not viable. Large amounts of ambient dust or smoke in the air pose no problem for this method, because, the use of air purge collars for harsh environments allow the camera’s optical components to be effectively kept clean.

User-Friendly System

The IRIScan FS early fire detection system has been given a modular design, making it exceptionally user-friendly. Furthermore, the IRISvisual software controls all of the system’s functions, with various alarm levels designed to flexibly adapt to any application requirements.

The temperature threshold already mentioned can provide an initial warning, but optional, additional thresholds are also possible. These can be set so that, if exceeded, the plant manager can send an urgent alarm directly to the fire service.

Once the software has detected that a critical temperature threshold has been exceeded, visual and acoustic signals are provided to the user on the PC while the software simultaneously records current infrared videos or images.

The Optris infrared cameras produce a thermal image, showing critical temperatures.

The system can be adapted to the customer’s requirements, meaning that, for example. alarm and status information can be displayed in the control room, in-situ, or sent via a network, e-mail, or SMS.

A single or multiple infrared cameras can be installed, depending on the customer’s requirements. In applications where a larger area needs to be monitored, cameras can be mounted on a pan-tilt head to systematically monitor the whole area.

The software can combine the images obtained via the swivel head into a single, composite image. It is also possible to fit an additional color CCD camera as part of the installation so that traditional video images can be recorded.

Traditional video allows the area to be identified more easily, should an increase in temperature be detected or an alarm is triggered. Users can also control the pan-tilt head manually from the control computer, should they need to examine specific areas in more detail.

Reliable Infrared Cameras as Core Components

As well as flexible, intelligent software, infrared cameras from Optris are central elements of the IRIScan FS system.

Connecting the Optris camera to both the supervisory hardware and the control computer is easily achieved via the USB interface. Where distances of over 20 meters between a PC and a thermal imaging camera must be covered reliably, a USB server equipped with an Ethernet connection is used. Depending on the system’s specific requirements, IRIS will select the most appropriate infrared cameras.

With Optris we have a very wide spectrum of different devices, so that we are always able to select the optimum resolution and the appropriate lens.

Kirsten Köhn, Managing Director, IRIS

This is a key advantage of working with Optris, and IRIS also obtains accessories directly from the manufacturer.

The infrared cameras can be equipped with weather protection housing or cooling housing, depending on the application’s environmental conditions. Because the infrared cameras are highly compact, integrating them within any application is straightforward.

Reliability is an important extra criterium in the selection, according to Köhn: “We are very confident with the quality from Optris - in the past we only experienced failures very rarely.” Service calls for installed IRIScan FS systems are very rare. Kirsten Köhn goes on to summarize, “Overall in the cooperation with Optris, who also offer an unbeatable price-performance ratio, has always brought positive experiences,”.

Using the flexible IRISvisual software, the parameters, for example, such as the temperature thresholds, can be adjusted very simply. If the multi-stage temperature thresholds are exceeded, the system automatically triggers the corresponding alarm.

Further Developments

IRIS continues to develop and expand the functionality of its fire early detection system. The system’s software is being continuously improved, for example, the latest version has seen the integration of object detection.

This particular upgrade was in response to most frequent false alarms resulting from the hotter parts of a vehicle – such as a forklift truck’s exhaust. The object detection feature is able to identify the forklift truck, therefore ensuring that the alarm is not triggered.

With this and other key functions, IRIS is continually striving to improve the user-friendliness of its system, and enhancing its ability to extend to other applications.

Acknowledgments

Produced from materials originally authored by Kirsten Köhn from IRIS GmbH and Torsten Czech, from Optris GmbH.

This information has been sourced, reviewed and adapted from materials provided by Optris GmbH.

For more information on this source, please visit Optris GmbH.