In this interview, AZoSensors talks to Neil Hannay, a Senior Development Engineer at Titan Enterprises, about the customization of liquid flow meters for a variety of applications

Please tell us about Titan Enterprises and what you do

Based in the South West of the UK – Titan Enterprises is a company specialising in both off-the-shelf and custom high-performance flow measurement systems. We supply to a diverse range of applications in markets ranging from healthcare and pharmaceuticals, chemical process plant measurements, automotive fluid metering and hazardous measurements in petrochemical refineries, to beverage/beer dispensing.

With over 40 years’ experience in flow meter innovation - our philosophy of “pushing the envelope by trying to do things a little different and better” has resulted in sales of over 500,000 products into 50 countries worldwide and a repeat purchase percentage of 95%. Something we are justly proud of.

For companies looking to integrate flow measurement into a product, we can tailor the design of a flowmeter to match their exact application requirements and thus not compromise results with a less than ideal sensor. Typically, the resultant Titan device would be unique to that specific application but would still benefit from Titan’s well tried and tested modern manufacturing methods to ensure a competitive OEM solution. From an initial concept, Titan can offer a complete service from budget costings through prototypes, to full production.

One of the questions we are often asked about is cost, to which we say, “the value of a flow meter cannot be judged by price alone”. Often in industrial applications, the reliability of a product far outweighs the initial purchase price, as ‘downtime’ is extremely expensive. At Titan, we endeavour to produce devices that are inherently reliable but are manufactured using the latest and most economical production techniques.

How are Titan Enterprises able to modify their standard liquid flow meter products to meet specific requirements?

To remain competitive in today’s global market - Titan Enterprises has always focused on continual development of our products, for our portfolio and OEM customers.

The easiest customer OEM requests to accommodate are those that require minor modifications to our standard product lines. We have customers and distributors who ask for a different cable connector or length modification, and often they would like the product supplied with their branding, labelling or calibration. We can accommodate such requests, usually with a simple change in production, with little development required. Once the new version is accepted by our customer, we install the new processes under our ISO 9001 system and generate the customer-specific part.

Other customers who only require a minor configuration or calibration change outside of our normal production can often be accommodated on a product by product order basis. However, for flow meters that require a significant manufacturing process change, we do ask for a minimum order quantity to cover the additional development costs.

The only exception to this is for our high-pressure range of Oval Gear flow meters. These are typically built to order and so we have the flexibility to match most variants the customer might ask for. We often change materials, pressure ratings, electrical connections and port connections. We can even offer a dual pulsed output if required. Basically, if the customer asks for something specific on an Oval Gear flow meter we will always try and accommodate them.

In what ways can Titan Enterprises modify its liquid flow meter products for a specific requirement?

When a customer comes to us with a complex flow measuring problem that cannot be solved by anything in our portfolio, or indeed off-the-shelf from anyone else, this where we will suggest a development project to create an optimised flow meter.

Bespoke product developments take longer than supplying a modified off-the-shelf product. For a successful outcome, delivered in a timely fashion, it is critical that they have a clear definition of the ‘customers desired product’ requirements. Though small customer design changes often occur, as the project develops, we strive ultimately to produce what is required for the target application or process within the pre-agreed price range.

Some examples of modifications to standard products from customers include changing the housing to fit a specific footprint and the addition of extra temperature and conductivity sensors into the design.

Can you share some examples of customization for specific applications?

Yes, of course. One of our most popular product ranges for customisation is our Oval Gear flow meters. We have a standard range of Oval Gear flow meters covering flow rates from 0.01 to 500 lpm and for most of this range, we have designs that can operate with pressures up to 700 bar and temperatures up to 150oC.

A recent example of a customised Oval Gear flow meter we produced, was for a device capable of operating up to 900 bar operating pressure with full certification for offshore use with an oil processing company. We designed, built, certified and tested each unit with our own 1000 bar hydraulic pressure testing equipment, with customer specified pipe fittings.

Fig. 1 High-pressure Oval Gear meters with customer-specific connections

For a different customer, we installed a second pulse detection device to enable dual pulse for flow direction as well as flow measurement. As these larger Oval Gear flow meters are usually built to order, we can usually cater for any customer-specific requirement.

A more complicated Oval Gear device was required for a customer measuring tar flow. To solve this tricky application, our bespoke Oval Gear flow meter design incorporated a hot oil jacket to ensure the tar flow stayed molten at all times. This took a little more design time to ensure the unit was fit for purpose, but we were happy to do that for the customer.

Fig. 2 Oil Jacketed Oval Gear meter

With our ultrasonic and turbine flow meters, we often have requests from customers wanting to integrate our devices into their existing systems. In these circumstances, the challenge is to modify the outer design or footprint of our device whilst not compromising the performance of the flow meter. This is where our team of experienced design engineer’s expertise comes into its own, producing 3D modelling first, to ascertain potential designs before committing to a CNC or 3D printed prototype.

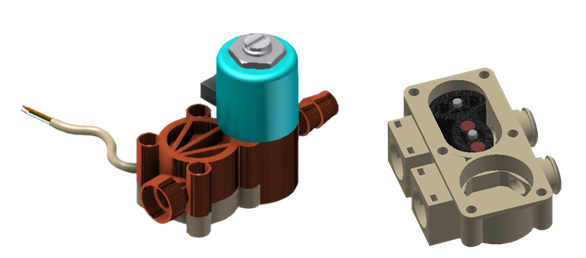

At the end of 2019, we were asked to produce an integrated turbine and solenoid control valve as well as a dual Oval Gear and turbine cartridge type flow meter, to enable accurate dosing of both viscous syrup and water simultaneously.

Fig 3. Dual device CAD Modelling: Valve with turbine flowmeter and Dual Oval Gear/turbine device

These types of product development are normally short-term modifications. They can often be prototyped in weeks and put into production in a few months, depending on the final specification agreed with the customer. Longer-term developments are where we are asked to develop a completely new device from concept to product, using our expertise. The focus technology for Titan at present is Ultrasonic small bore flow meters, so we have a number of ongoing customer developments in this area expanding the flow range performance and price of our current systems, whilst producing a customer-specific product.

What other areas has Titan experience in supplying application-specific optimized solutions for?

If the flow requirement is close to our current operating ranges, we are always willing to look into the application to try and help, assuming the commercial numbers and timescales make sense.

Over the years, we have been involved in developing devices for food, robotics, high power telescopes, agriculture, chemical, wind turbines, and analytical instrumentation. We find these application-specific developments often help us to improve our standard product line whilst solving the customer’s specific problem.

We are always happy to discuss an application with a customer to ensure any solution offered will give them the results they need. We are not in the market of selling flow meters for the sake of it. We want to have happy customers using our products reliably. Most of our business is from repeat customers due to this operating philosophy which has been ingrained to us from our MD Trevor Forster and we work hard to maintain it.

How does Titan ensure quality is preserved after adapting its liquid flow meter products?

Our Titan products are manufactured to ISO 9001 2015 to ensure reliability of supply. So for bespoke units, once we have a new design which has been tested and approved by the customer and our manufacturing team; the drawings, bill of materials and procedures are placed under the ISO 9001 remit to ensure reliable, repeatable building and testing of the flow meters occurs.

For a bespoke or OEM flow meter that requires injection moulding of specialist parts, a customer-specific tool is provided just for their product. This ensures the tool is maintained as the customer requires, but also that the flow meter design is kept optimised to their needs for their product alone.

What additional benefits does working with Titan Enterprises, developing an application optimised flow meter system, offer?

An interesting question. Titan prides itself on the amount of time and resources we put into research and development of new flow measuring devices and we will always be willing to discuss a customer’s application.

First off, we will look to see if an existing product can fit the desired process and then look to see if it is an area we have the expertise to resolve. As mentioned earlier, the one thing we will not do is offer something that is not suitable or make false promises on project developments to customers. We value our customer and distributor base and want to ensure our flowmeters are used correctly to give reliable, optimal performance.

What flow meter technological developments is Titan Enterprises currently working on?

As you would expect, over the last six months enquiries for bespoke liquid flowmeters have not been as forthcoming as normal. However, we are still working on a few interesting developments.

For example - we are currently in the final stages of an ultrasonic meter design specifically for a water management company. This has been an interesting development with a wide flow range remit and specific customer design and materials. Taking our Atrato® and Metraflow® Ultrasonic Flowmeter product design understanding, we have pushed both the electronics and physical design to improve the overall performance window whilst reducing costs. We now have a very nice product in its final stages of testing in the field with the customer, fitting into their specific branding and performance requirements.

Most recently, we have been asked to join in a very exciting project to develop an ultra-low flow device, down to 0.01 ml/min for a variety of water and organic solutions. This is a big challenge. Any existing flow meters capable of measuring such ultra-low flows, are very expensive and work only within limited parameters. Using our patented ultrasonic technology, we are hopeful we can get there and have been testing a few new ideas to make it possible. Unfortunately, we cannot share the details of these exciting developments with you at the moment!

Fig 4. Examples of bespoke meters designed by Titan Enterprises Ltd.

Fig 4. Examples of bespoke meters designed by Titan Enterprises Ltd.

About the interviewee

Neil Hannay is a Senior Development Engineer at Titan Enterprises. He joined the company just over two years ago to manage the development of new flow measuring systems.

His previous experience over the last 25 years includes project managing industrial research and development, focusing on process devices and processes for gas and liquid systems for the oil and gas, chemical, food, water and pharmaceutical sectors.

Neil began his career in the water treatment process and equipment design, focusing on flocculation, ozonation and biological treatment processes and devices and then moving to biological and chemical process development in the food and chemical industries. Over the years, Neil has accumulated expertise in gas and liquid flow control and measurement and customer process integration.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.