For any desirable product, reliability is a key component. Reliability, combined with accuracy, performance, quality and cost are what enable a user to establish a product's overall value.

These factors drive decisions, so determining what makes a product reliable and also understanding how the environment and reliability of a product are related is vital. This article outlines the reliability of ultrasonics utilized in chemical level sensing.

It focuses more specifically on how a reliable transducer is key for a well-performing, long-lasting ultrasonic sensor.

Ultrasonics can be selected and used much more effectively in a range of environments, including wastewater and turbulent water, or the chemicals employed with processing – even those once believed to be incompatible with the technology.

In fact, ultrasonics can be optimal technology over a wide variety of process industries, from paper mills to semiconductor fabs to agricultural chemicals. Ultimate performance results can be achieved by understanding what features in the ultrasonic design of the sensor and the transducer influence sensor reliability when utilized in or with chemicals.

For level measurement, ultrasonic sensors are a very cost-effective solution, and recognizing how to select the most reliable products lowers the cost of ownership, enables control over the desired outcome, and can minimize the requirement for more expensive technologies.

Overview

Ultrasonic sensors are frequently utilized in a wide range of non-contact distance measuring applications, for instance, monitoring the level of solid materials or liquids in tanks. These devices all work in the same fundamental way. They transmit a short burst of ultrasonic sound towards a target, which then reflects back to the sensor.

These types of sensors measure the time from when the sound pulse is transmitted until the echo returns to the sensor and calculates the distance to the target by utilizing the speed of sound in the medium.

Yet, not all ultrasonic sensors are the same. It is crucial that all aspects of the sensor work dependably and properly to ensure that accurate distance measurements are continually gathered in order to be a quality product with high reliability.

Some people may think that quality does not influence the overall reliability of an ultrasonic sensor, but this article emphasizes the fact that true quality results in long-lasting products which continue to perform and meet specifications for years, even decades.

Once this key point is understood, users will save money on their projects and for their companies, as they will always select high-quality sensors which are made with high-quality components that will exceed expectations for an incredible period of time. The costly downtime associated with using inferior products will also be eliminated.

There are a number of key factors which can influence a sensor’s reliability, and some of these will be outlined in this article. The electroacoustic transducers that transmit the sound pulses and receive the return echoes are the most vital components in ultrasonic sensors.

The craftsmanship of the transducer design and the quality of the transducer can both drastically influence the performance and reliability of the sensor in which it is employed. As substandard transducers are screened out long before they hit the market, this also lowers the infant mortality rate of the products they go into.

There are two key areas that must be considered that affect transducer reliability. The first is to ensure that the transducers have the correct mechanical and electroacoustic design for each application. The second is how the transducers are created.

The Design

As one affects the other, the acoustic and the mechanical design are interrelated in many ways. So, for the correct transducer design, a strong understanding of both is crucial. There are also some clear differences between the two.

The acoustic items include beam type, frequency, beam angle and the attenuation of sound, amongst others. The mechanical items include the materials which are utilized in fabrication so that the transducer not only holds up but also performs well in multiple mediums, environments and applications.

The relationship between the acoustic and mechanical design items with the environment is crucial for the design and the assessment of the reliability of ultrasonic sensors and transducers.

There are a number of chemicals that can influence the attenuation and affect the perceived reliability and performance of ultrasonic level sensors in such environments. Designing a transducer that is modified for the attenuation of the environment will provide results that are more accurate, and it will help the ultrasonic in its performance within the medium for longer.

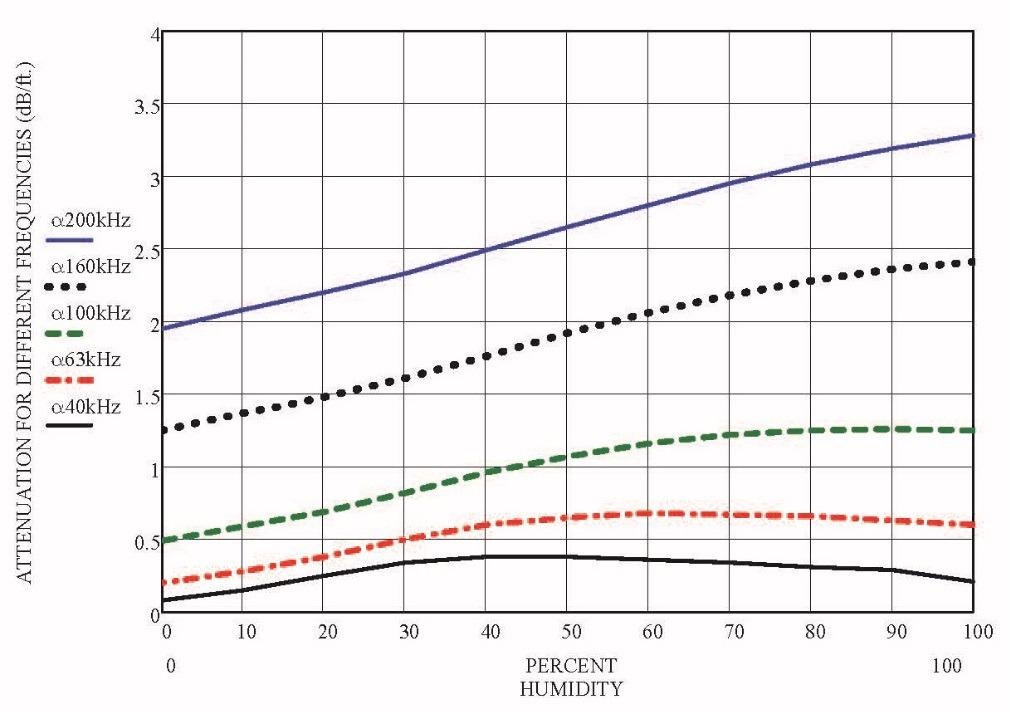

The attenuation of sound in the air as a function of humidity for different frequencies is shown in Figure 1. When various chemical vapors are introduced, this relationship becomes more complicated.

Figure 1. Attenuation of Sound in Air in dB/ft. as a Function of Percent Humidity for Frequencies of 40 kHz, 63 kHz, 100 kHz, and 200 kHz. Image Credit: Massa Products Corp.

If these aspects are properly considered with choosing the frequency of the transducer design, the ultrasonic sensor utilized with certain chemicals can give the user the impression it is unreliable.

In reality, ultrasonics themselves are not unreliable, but rather due to misunderstanding, they have been misused. So, reliable and desirable level measurement can be attained with ultrasonics if a transducer is designed with respect to these influencing factors, like the effects of specific chemicals.

A number of chemicals can also attack various materials, which can even influence the transducer within a sensor housing. Utilizing any ‘off the shelf’ transducer is not the most reliable choice in sensor design. The transducer must be designed to withstand the challenges presented in the setting where it is needed.

This means the transducer must be constructed with proper materials that can hold up to the environment without interfering with the acoustic performance of the transducer and be built to withstand the attenuation of sound issues.

Dependable transducer design must start with a proper characterizing of the conditions in which the sensor will be exposed to and required to operate. In order to optimize performance and durability, the mechanical challenges that may exist and the acoustic properties of the environment must also be understood.

This is true for both ultrasonic and sonar transducers and systems. In order to achieve the desired operation in the environment, the materials must work well with the acoustics, and both the materials and the acoustics have to be fashioned.

The quality of the transducer within greatly enhances the quality and the reliability of the sensor being built or used and understanding the materials and the acoustics can give a user the edge. In different mediums, acoustic properties change and can give a false impression that they will not work as well as other technologies.

Many new truths regarding the performance, success, reliability, and cost-effectiveness of ultrasonic and sonar measurement in a variety of applications and mediums can be discovered when the transducer/sensor supplier is truly knowledgeable with respect to the materials and the acoustic properties and is skilled in the manufacturing of electroacoustic devices.

Much time and money can be saved with this knowledge and the acoustics must be discussed further to explore this concept in greater detail. Transducers can be designed to have different acoustic radiation patterns and to work at different ultrasonic frequencies. As it travels through the air, sound energy is absorbed.

The higher the frequency, the bigger the attenuation of the sound pressure for each inch in the path from the transducer to the target and then back to the transducer. So, the frequency of the transducer will have to be lower the further its distance to the target.

For any given application, an acoustic specialist is able to identify what the correct beam pattern and frequency should be. It is wrong to assume that certain applications require some ‘standard’ frequency or beamwidth.

The more knowledgeable a transducer designer is about an application, the better the transducer and sensor will be to ensure performance that outlasts all others. The design of the radiation pattern of the transducer is also crucial.

Most ultrasonic sensors utilize transducers using the teachings of the U.S. Patents 3,928,777 and 4,011,473 that were issued to Frank Massa in 1975 and 1977, respectively. For any frequency of operation, transducers of this design have a 10° beam angle (8° system beam angle).

This is ideal for flat reflecting surfaces, but a broader beam angle is needed if the reflecting surface is uneven, turbulent, or tilted relative to the axis of the sound beam.

Sensor Reliability

A sensor is actually a system. The system includes the electronics, transducer and sensor housing. Ultrasonic sensor reliability is greatly influenced by the quality of the transducer and the relationship between the materials and electronics.

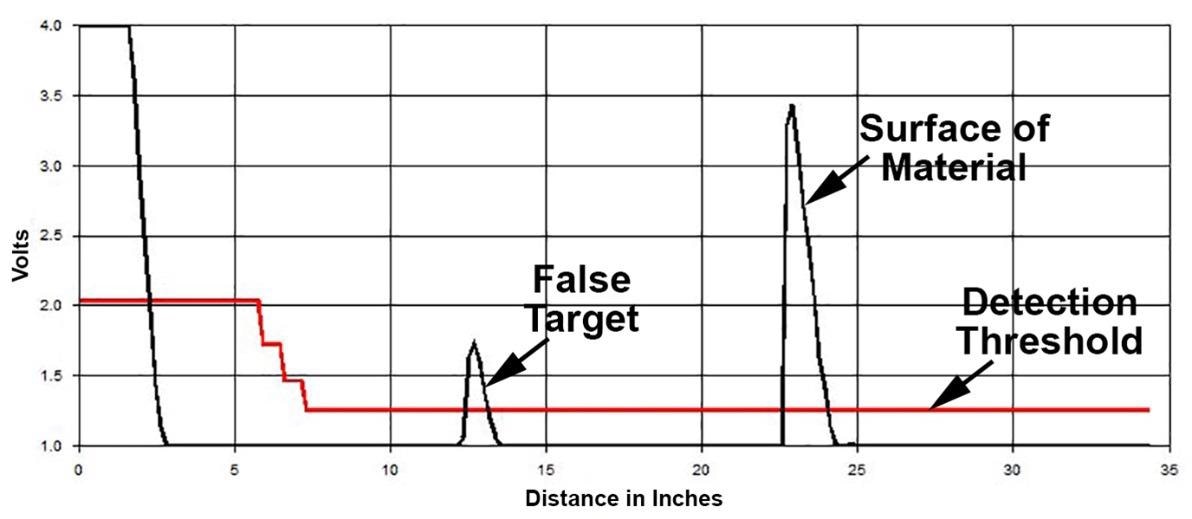

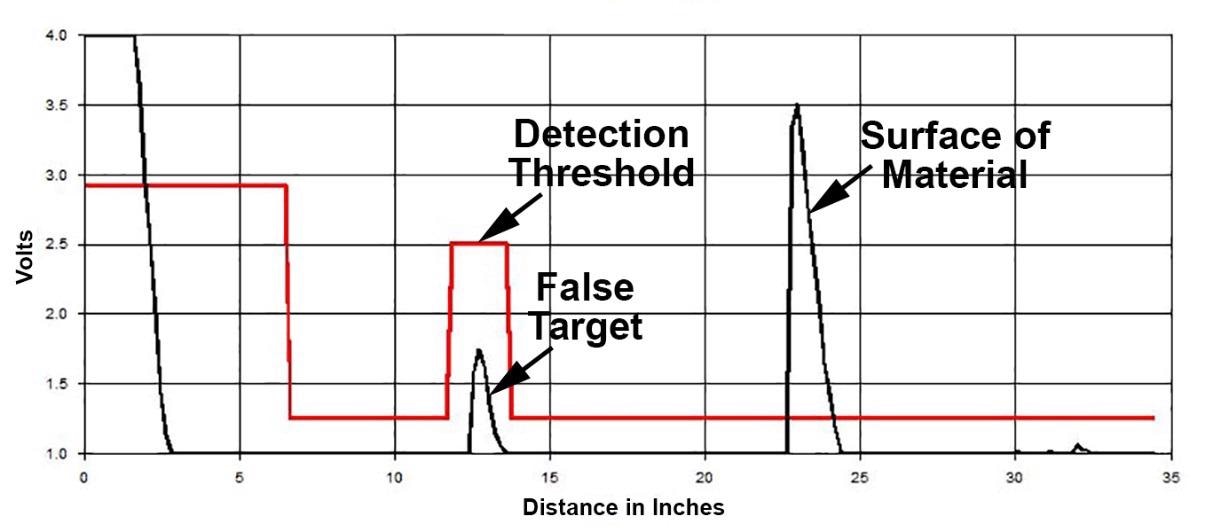

A lower level of complexity in electronics and a higher quality transducer lead to a better sensor which also costs less. Ultrasonic waveforms can be used to establish if there are any reflecting objects which could result in unwanted echoes or false alarms.

Part of a high-quality design is the ability to adjust the thresholds of detection to rule out false echoes in any given material and increase the overall reliability of the ultrasonic sensor.

Waveform capture also enables troubleshooting, which permits quick assessment in real-time. Figures 2 and 3 show how these adjustments can be made by MassaSonic® Sensors.

Figure 2. Ultrasonic Waveform from a MassaSonic® PulStar® Plus Sensor Showing a False Target Being Detected Instead of the Echo from the Surface of a Liquid or Solid Material. Image Credit: Massa Products Corp.

Figure 3. Ultrasonic Waveform from a MassaSonic® PulStar® Plus Sensor with the Same Targets As in Figure 2, But with the Detection Threshold Modified to Ignore the False Target. Image Credit: Massa Products Corp.

Fabrication

Manufacturing is much more than simple assembly. To build transducers and sensors that are high in quality and reliability correctly, it is crucial to possess a high level of expertise, skilled and knowledgeable workmanship, and cooperation between production and design engineering so that the best possible product is created.

The facility should have high-quality procedures and controls in place, and to control the quality of the manufacturing, the production line must contain the correct fixtures, tools and processes.

To construct instruments of this sophistication, highly qualified people must be employed. They must be trained in the proper methods to build, seal and test the ultrasonics – by doing this, the failure rate of the products is greatly reduced and even eliminated.

Conclusion

The main factor that affects the quality and the reliability of an electroacoustic sensor is implicit expertise in the design and manufacture of electroacoustic transducers, and this is the case for both sonar and ultrasonics.

It is only with this full knowledge that an electroacoustic sensor can be optimized to perform properly in challenging and caustic environments. Common transducers are not as ‘plug and play’ as once thought.

The belief that they are is what has led to the common misunderstanding that ultrasonic sensors are unreliable when utilized in certain environments. If a sensor and transducer are optimized for the environment, then ultrasonic technology is a successful, cost-effective choice for level measurement that will lead to a lower cost of ownership.

Massa designs, engineers, and manufactures all of its transducers and systems in-house and has done so for more than 70 years. There is fluidity in Massa design from conception through production, and this is the case for sensors, transducers and systems that are utilized in both liquid and air.

In all industrial and commercial products, Massa uses the same quality controls in place for the sonar systems manufactured for the U.S. Navy. Some MassaSonic products are utilized in an industry that was deployed in the 1980s and are still running in the field without replacement required.

Massa has created advanced sonar products used on the submarines that protect the American people for years with zero rejects.

Acknowledgments

Produced from materials originally authored by Dawn F. Massa Stancavish and Donald P. Massa from Massa Products Corporation

This information has been sourced, reviewed and adapted from materials provided by Massa Products Corp.

For more information on this source, please visit Massa Products Corp.