The non-contact temperature measurement devices offered by Optris feature state-of-the-art interface concepts, which enable easy integration across networks and automated systems. This technical note outlines the assembly of thermal imagers via an RS485 module and online infrared thermometers via PLC using PROFIBUS DP.

Image Credit: Optris GmbH

With regards to PLC environments, the PROFIBUS is typically accepted as one of the most used bus systems. With respect to the production process and building automation, the bus system epitomizes a secure and rapid communication exchange between the control units and the single bus partners.

Each set up of the PROFIBUS network is almost identical every time. For example, you can see the control unit on the one side, a SIMATIC S7 of SIEMENS for example – also known as the master system or active station. On the other, you will find the bus partners, the so-called slaves – also known as passive stations – these can be either sensors or actors.

All Optris infrared temperature sensors are related to the processor field communication – particularly to the PROFIBUS DP version.

Image Credit: Optris GmbH

Integration of Optris PI Thermal Imaging Camera

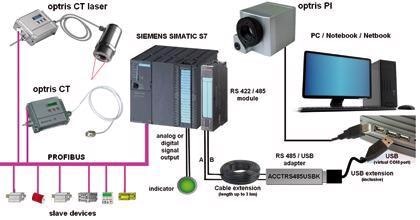

There is now a simple solution available to incorporate the thermal imager optris PI into PLC environments. The solution is predicated on a major benefit offered by the master system to support the connectivity to other networks such as RS485.

This facilitates the system set up over long distances (up to 3 km) between the infrared camera and the PLC as you can see in the illustration above. The optris PI thermal imager is typically connected to a PC, and the imager’s software optris PIX Connect evaluates and displays the temperature data.

The software must be adjusted in relation to external communication. The RS485 connection ‘Comport’ mode can be selected using the software menu TOOLS – CONFIGURATION – EXTERNAL COMMUNICATION, as demonstrated in the illustration below.

The optris RS485 kit is available (product code: ACCTRS485USBK) for the integration of the imager into a PLC system. A virtual Comport at the PC can be generated by using separate software, which comes as standard in the RS485 kit.

The RS485 module is connected via the virtual Comport to the software optris PIX Connect; the RS485 module then transfers the data to the SIEMENS S7 PLC via A and B cables.

The first illustration in this article exhibits the configuration of the hardware that is based on a RS485 connection between the optris PI camera and the SIEMENS S7 PLC, including:

- optris PI400

- optris RS485 kit (ACCTRS485USBK)

- SIMATIC S7-300, CPU 313C-2 DP (processor with a PROFIBUS module)

- SIMATIC S7-300, front module with digital and analog outputs

- SIMATIC S7-300, CP 340 (communication processor with RS422/485 interface)

- Software STEP 7 (to configure the SPS regarding the RS485 and the PROFIBUS module)

Image Credit: Optris GmbH

Image Credit: Optris GmbH

Integration of Optris IR Online Thermometers

In addition to the standard output signals of infrared thermometers, including voltage, power and thermocouple, Optris offers additional digital interfaces with each two-piece device (sensor head and electronic box).

Available in each box, a free slot can be used to install an appropriate digital interface card as shown in the illustrations above.

The installation is extremely simple. A so-called GSD file (a GENERICSTATION DESCRION FILE) belongs to each field-bus partner. The file can be loaded into the PLC to ensure proper communication is established between the master device and the slave.

The GSD file for Optris’ PROFIBUS interface is available on a CD which comes with the device. It includes crucial information such as the communication orders to request the object temperature or to set emissivity values.

This information has been sourced, reviewed and adapted from materials provided by Optris GmbH.

For more information on this source, please visit Optris GmbH.