Unmanned aerial vehicles (UAVs), otherwise known as drones, are aircraft that operate without an onboard human pilot. They are integral components of a complex unmanned aircraft system (UAS), which includes a ground-based controller and a communication mechanism enabling interaction between the controller and the UAV.

Image Credit: Superior Sensor Technology

During operation, the UAV can function autonomously via internal electronics or be remotely controlled by a human operator. However, in both scenarios, sensors play a crucial role in ensuring the accurate execution of the UAV’s intended actions.

UAVs have transformed the aviation landscape by providing distinct benefits, such as remote sensing and surveillance capabilities, all without requiring a human pilot.

Essential to the functionality of UAVs are a multitude of sensors, which measure environmental conditions and aid in system adjustments. These sensors are paramount in guaranteeing the safe and efficient operation of UAVs.

The following eight sensors are crucial in UAVs:

- Gyroscopes: These sensors detect and measure the degree of tilt, rate of rotation, and angular velocity of the UAV.

- Accelerometers: Used to detect linear movement along any axis of the UAV.

- Barometers: These sensors measure air pressure to maintain a stable altitude.

- Pitot Tubes: Used to measure airspeed (specifically for winged UAVs).

- Angle of Attack (AOA): AOAs determine the aerodynamic forces of winged UAVs.

- Magnetometers: These sensors measure magnetic field strength and direction to establish the heading of the UAV.

- GPS: GPS establishes the positioning of the UAV.

- Obstacle avoidance sensors: These sensors prevent UAVs from colliding with objects.

Figure 1. UAV Roll, Pitch and Yaw. Image Credit: Superior Sensor Technology

This article discusses the first four sensors, which rely on extremely accurate pressure sensors. Gyroscopes, accelerometers, and barometers can be combined to build an Inertial Measurement Unit (IMU) that measures crucial parameters like the UAV's roll, pitch, and yaw. The pitot tube simultaneously establishes airspeed. Combining these sensors results in reliable and precise navigation and control that ensures safe and efficient UAV operation in any environment.

The Role of Differential Pressure Sensors in IMUs

IMU systems rely on different pressure sensors to detect and alert the UAV to make any necessary adjustments. These sensors are vital in three specific areas of the system. Their fast response time to pressure changes allows the UAV to make adjustments for peak performance.

Barometer

Altitude is an influential factor for air pressure, with pressure decreasing as height increases. To accurately track changes in altitude, the use of a barometric pressure sensor is a must. This device enables quick measurements of atmospheric pressure to be made, ensuring the UAV is flying at the appropriate elevation.

Accelerometer

Accelerometers measure velocity’s rate of change over time. They are a key part of the navigation system of UAVs and are responsible for determining the aircraft’s orientation and movement.

Differential pressure sensors are seamlessly integrated into accelerometers within UAVs to continuously monitor alterations in air pressure at the aircraft's nose. This ensures a consistent rate of movement, even when faced with changing wind conditions and other variables.

Gyroscope

Gyroscopes measure angular movement and can incorporate differential pressure sensors. These systems measure the changes in air pressure due to changing angles, which applies to all movements on any axis, whether pitch, roll, or yaw.

The Role of Differential Pressure Sensors in Pitot Tubes

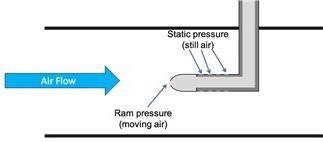

Positioned on the exterior of a UAV, Pitot tubes employ a differential pressure sensor to gauge the aircraft’s airspeed relative to its environment.

These tubes assess the disparity between static pressure, representing still air, and ram pressure, indicative of moving air compressed by the UAV’s forward momentum. As the UAV’s velocity rises, the gap between these pressure readings amplifies accordingly.

Figure 2. Pitot Tube Diagram. Image Credit: Superior Sensor Technology

Superior Sensor’s Technology Advantage

Superior Sensors has pioneered the groundbreaking NimbleSenseTM architecture, an unparalleled integrated platform. This unique system merges advanced pressure sensing technology with customizable building blocks, delivering unmatched accuracy and reliability while minimizing system costs.

The company is revolutionizing UAV performance with its cutting-edge ND Series of pressure sensors. The ND015A barometric pressure sensor measures atmospheric pressure with extreme accuracy, ensuring stable altitude maintenance for drones.

Additionally, the Multi-Range differential pressure sensors, such as the ND005D, offer highly accurate airflow measurements, allowing UAVs to travel at precise speeds. Together, these sensors establish a new benchmark for UAV performance by offering:

Lowest Noise Floor

Differential pressure sensors used in UAVs encounter a significant challenge due to noise generated by both the drone and external elements such as wind.

Superior’s pressure sensors incorporate advanced digital filtering technology, effectively preventing noise from impacting system performance. This ensures that any error signals stemming from noise are eliminated before they can impact the accuracy of air pressure readings.

Highest Levels of Accuracy

Small fluctuations in altitude, speed, or angle of attack demand meticulous monitoring to ensure that a fast-moving UAV maintains a steady trajectory. Utilizing a differential pressure sensor renowned for its utmost accuracy is paramount in mitigating any potential disruptions to the UAV’s path.

The ND Series stands out for its exceptional precision, boasting an effective resolution of 19 bits. This enables measurement precision within 0.05 % of the designated range and maintains a total error band (TEB) of merely 0.10 % of FSS.

Fastest Response Times

In addition to accuracy, the speed at which a pressure sensor updates its measurement data is also important for ensuring a UAV's optimal function. The ability to quickly receive updated pressure measurements enables the drone to maintain precise positioning more efficiently.

In this regard, the ND Series offers configurable options for update rates, which can support speeds as fast as 2.25 milliseconds.

Sensor Customization and Flexibility

One significant advantage of incorporating a single, adaptable sensor into the design of UAVs is that it can be customized for various applications on the drone, thus enhancing design efficiency and reducing product cost.

With the ND Series, all sensors are pin-compatible, meaning the same sensor can be used for all UAV pressure sensing requirements. Depending on the application, each sensor can be optimized for specific purposes and offers customizable features such as pressure range, bandwidth filter, and output data rate.

Conclusion

To ensure successful operation, UAVs are highly reliant on receiving a consistent flow of flight information. Pressure sensors are crucial in providing this data, which allows drones to fly smoothly and without interruption.

The sensors are required to meet rigorous demands - rapidly filtering environmental interference, maintaining pinpoint precision under changing conditions, and being adaptable to the specific needs of the UAV market.

Superior Sensor Technology’s ND Series is ideal for those requiring unmatched design flexibility and the highest performance. Visit the ND Series product page for additional information on the ND Series.

This information has been sourced, reviewed and adapted from materials provided by Superior Sensor Technology.

For more information on this source, please visit Superior Sensor Technology.