Aug 5 2016

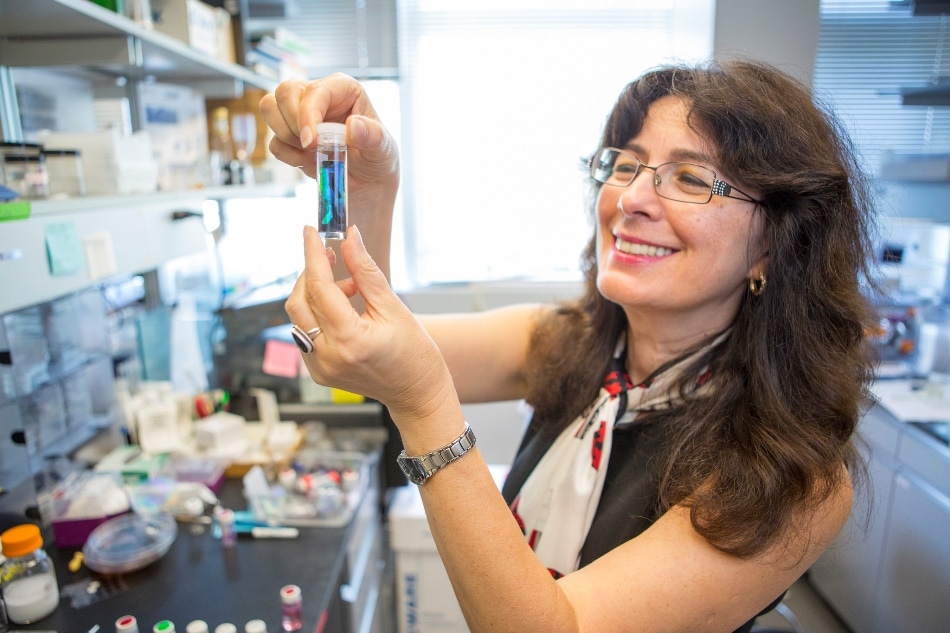

Harvard Prof. Joanna Aizenberg

Harvard Prof. Joanna Aizenberg

Validere, a new company cofounded by Harvard engineers and scientists will be marketing a sensing technology invented at Harvard University. This novel technology is designed to perform instant, in-field characterization of the chemical make-up and material properties of unidentified liquids.

Validere has already raised a primary round of seed capital and has signed a worldwide exclusive licensing agreement with the Harvard University to pursue applications in liquid identification and quality assurance.

The company is focused on developing the licensed technology known as Watermark Ink (W-INK), into a pocket-sized device that can be carried by first responders to swiftly detect chemical spills, or used by officials to authenticate the fuel grade of gasoline instantly at the pump.

Compared to other methods used for identifying and verifying liquids, Harvard’s solution is instantaneous, portable and inexpensive.

The W-INK was developed in the laboratory of Joanna Aizenberg, the Amy Smith Berylson Professor of Materials Science at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) and a Core Faculty member of Harvard’s Wyss Institute for Biologically Inspired Engineering.

The W-INK concept makes use of the optical and chemical properties of precisely nanostructured materials to differentiate liquids based on their surface tension. Marko Lončar, Tiantsai Lin Professor of Electrical Engineering at SEAS, also assisted in its development.

Just like the litmus paper in a chemistry lab that changes color when it detects the pH of a liquid, the detector changes color when it makes contact with a liquid with a specific surface tension. The color-changing strip can be designed to react precisely to the unique surface tension displayed by any liquid.

This idea advanced swiftly through Harvard thanks to an organic system that facilitates progress from discovery to application. We first developed the technology from basic research in my lab at SEAS. The Harvard Office of Technology Development (OTD) guided and supported our commercialization strategy through its Physical Sciences and Engineering Accelerator. Out of this virtuous cycle of innovation Validere was spun off with a viable commercial product.

Joanna Aizenberg, Professor, Harvard

The W-INK technology received early support from the Air Force Office of Scientific Research and a proof-of-concept contract from the U.S. Department of Transportation, and is likely to have significant applications in government and industry.

“Validere translates this technology to create inexpensive, one-time-use test kits that can be used anywhere in the field to visually identify unknown liquids, all without the need for a dedicated power source,” said Ian Burgess, co-founder, CEO and CTO at Validere, who co-invented W-INK as a doctoral student at SEAS and technology development fellow at the Wyss Institute.

“Many people focus on making hardware smaller, but miniaturization often turns out to be the easy part,” Burgess said. “What’s difficult, and what our solution does, is to simplify the readouts to a level that you don’t need a technician to interpret the results. Anyone in the field can immediately know, on the spot, how to respond to a sampled liquid.”

Harvard’s Physical Sciences and Engineering Accelerator offered seed funding that enabled Aizenberg’s team to move the technology from the lab to the pilot scale and attract more investment. The research team continues to tweak W-INK to widen its range of applications.

The W-INK technology has been described in several original publications such as the Journal of the American Chemical Society, ACS Nano and Lab on a Chip, in January 2016.

Since then, Aizenberg, Lončar and Burgess reported enhancements that facilitate a colorimetric test to determine the volatility of liquids. This new feature is illustrated in a paper published in Scientific Reports, and is of specific interest to the Department of Transportation (DOT).

The capacity to quickly profile the volatility of crude oil, which is frequently transported by railroad, would help make decisions regarding suitable transport containers at the point of extraction in the field, thereby helping to prevent accidental explosions.

DOT is also assisting development of test kits for assessing hazardous spills.

Aizenberg’s lab undertakes reverse-engineering tasks. The W-INK takes the role of two biological systems to accomplish a tunable device with properties that enable it to change colors when it makes contact with specific liquids. The bright colors on wings of certain species of butterfly are due to structure rather than pigment. The surface of each wing contains a system of miniature pores, the size of which establishes the perceived color.

Brittle stars, similar to starfish, are able to modify color from black to white by adjusting the position of pigmented cells within lens-like, light-focusing structures positioned in an array across the back of the star.

By integrating the two mechanisms in such a manner to react optically to liquid infiltration into chemically modified porous structures, Aizenberg’s team built a palm-sized liquid decoder and can be operated without a power source.

Engineered surface properties react to liquids to modify the interfacial chemistry of the test strip, which immediately causes related color changes or markers to emerge.

Aizenberg received support from the U.S. Federal Railroad Administration, and is currently heading research efforts to improve the sensing capabilities, while Burgess is leading Validere’s development of an interface device and software that will translate visual test results into suggestions for appropriate handling of identified liquids. The device along with disposable strips comprises customizable field test kits that can be tweaked to detect virtually any liquid mixture or liquid.

“The goal is to remove the element of human error from the identification and categorization of unknown liquids,” Burgess said.

In 2013, W-INK was chosen to receive the R&D 100 Award, which is referred to as “the Oscar of Innovation”, from R&D Magazine. The research underlying Harvard’s W-INK technology was supported by the Wyss Institute and grants from the Air Force Office of Scientific Research; the Natural Sciences and Engineering Research Council of Canada; and the U.S. Department of Homeland Security (DHS), administered by the Oak Ridge Institute for Science and Education, through an interagency agreement between the U.S. Department of Energy and DHS.