Jul 12 2017

The problem with water utilities is that if adequate chlorine is not added, dangerous bacteria that can lead to cholera and typhoid are not eliminated thoroughly.

On the contrary, excessive chlorine can lead to the formation of disinfection byproducts, example, chloroform, thus increasing the risk of cancer. Therefore, the quantity of chlorine has to be “just right” for the drinking water to be safe.

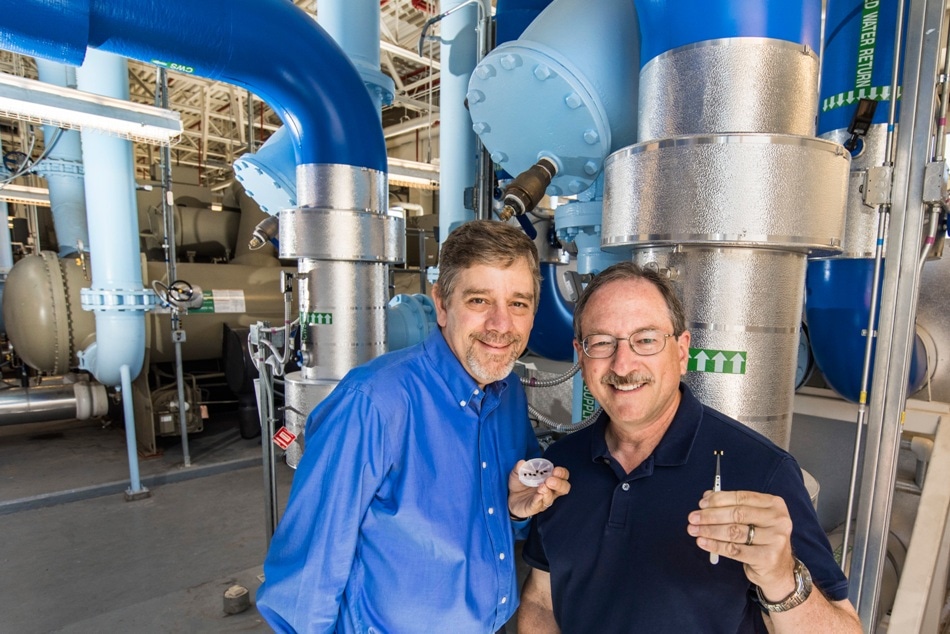

Sandia National Laboratories researchers Curtis Mowry, left, and Mike Siegal show their nanoporous carbon coated surface acoustic wave sensors. Their sensor forms the heart of Parker Hannifin’s Trihalomethane Water Analyzer that provides almost-instant feedback on the disinfection byproduct levels of water, before it reaches consumers. CREDIT: Photo by Randy Montoya.

Sandia National Laboratories researchers Curtis Mowry, left, and Mike Siegal show their nanoporous carbon coated surface acoustic wave sensors. Their sensor forms the heart of Parker Hannifin’s Trihalomethane Water Analyzer that provides almost-instant feedback on the disinfection byproduct levels of water, before it reaches consumers. CREDIT: Photo by Randy Montoya.

The permitted amount of disinfection byproducts, such as trihalomethanes, in drinking water is regulated by the Environmental Protection Agency (EPA). However, if water utilities want to monitor and regulate trihalomethane levels on their own, they must send water samples and wait for many weeks before they are tested by an EPA-qualified laboratory.

Collaborating with Parker Hannifin, Sandia National Laboratories integrated basic research on a fascinating form of carbon with a distinctive microsensor to develop an easy-to-handle, table-top tool with the ability to inexpensively and rapidly detect very low levels of the trihalomethane forms, namely, bromodichloromethane, chloroform, bromoform and dibromochloromethane.

According to Mike Siegal, Sandia Materials Scientist, water utilities no longer need to send samples to EPA-qualified labs, hire their own highly trained chemist to perform the EPA test, or buy an expensive mass spectrometer system to routinely monitor their trihalomethane levels and ensure cleaner drinking water for the public.

Recently, Parker Hannifin launched an automated online edition of the water analyzer for continuous monitoring of trihalomethanes.

Cool and controllable carbon coatings

The primary aim of the project was to develop a hand-held chemistry lab (similar to a tricorder) to detect hazardous, airborne chemicals, such as chemical weapons. A principal component of this lab-on-a-chip was a surface acoustic wave sensor. This SAW sensor works by vibrating a wave along a quartz sheet, said Analytical Chemist Curtis Mowry. By measuring how the wave changes on the SAW device, Researchers can tell how many chemicals are sticking to the quartz surface.

To a certain extent, this is almost identical to operating a playground parachute. The person holding the parachute can tell the difference between a bunch of balls and a child by how the parachute moves when they shake it. However, the quartz surface isn't very sticky, which limits its sensitivity. This is where a special carbon coating comes in.

Natural carbon occurs as common graphite formed of numerous layers of graphene sheets, as exotic diamonds and various other forms. Nanoporous carbon comprises of nanofragments of graphene sheets stacked and engineered to have numerous nooks and crannies in which chemicals can deposited. According to Siegal, in contrast to graphene or carbon nanotubes that have similar molecularly “sticky” surfaces, nanoporous carbon can be grown on virtually anything, even SAW devices.

In such a growth technique, also termed as pulsed laser deposition, graphite is zapped by using a laser at room temperature. The carbon atoms released in the process fly through a vacuum chamber and get deposited on the SAW sensor in a reproducible and uniform way. When just a meager amount of an inert gas was added to the vacuum chamber, Siegal was able to regulate and alter the total surface area as well as the density of nanoporous carbon coatings from being extremely fluffy to being solid like pure graphite.

Nanoporous carbon with a middling density is the most appropriate in the case of SAW sensors. Only three grams of such nanoporous carbon has as much surface area as a football field, yet is rigid enough t work for SAW sensors.

Extending the metaphor of the parachute, nanoporous carbon is similar to Velcro, capturing every ball that touches the parachute.

The first time we applied the carbon coating, it turned out to be a thousand times better than any organic coating that Sandia, or anyone else, had ever studied to adsorb volatile chemicals.

Mike Siegal, Sandia Materials Scientist

Mowry further stated that “The winning combination was teaming up with Siegal and his nanoporous carbon coatings and using larger, almost retro SAW devices.” In the case of SAW devices (and also for most electronics) smaller is more advantageous and advanced. At this time, Sandia’s newest and smallest SAWs used higher frequency vibrations with more advanced microelectronics. However, they were also very costly, tough to produce and less reliable. Using larger devices, roughly the dimensions of a Tic Tac, that were state-of-the-art in the '90s, it was easy to apply the nanoporous carbon coating- which increased the sensitivity a thousand times more than decreasing the size- and dramatically decreased the cost of the device.

The journey from basic science to commercial product for the public good

The research was initiated in the year 2002 and was developed through many years of chemical sensor research and development. Mowry attempted to create a sensor for detecting volatile organic contaminants, such as chemicals from industrial leaks or spill, in water. His lecture at a water quality conference attracted the attention of a Parker Hannifin Engineer and culminated in the collaboration in 2006.

It took many years to cross the “valley of death” from potential research to commercial product. However, by the year 2011, Parker Hannifin launched its first Trihalomethane Water Analyzer. The subsequent, online edition of the analyzer has the ability to automatically monitor individual trihalomethane levels on an hourly basis. When compared to other companies, Parker Hannifin has the largest number of dedicated trihalomethane analyzers instated in North America.

Other potential uses for nanoporous carbon coated SAW sensors include detecting homemade explosives, contaminants in air an water and almost any volatile or semi-volatile organic compound, said Mowry.

Additionally, Siegal and his colleagues are investigating the use of nanoporous carbon for battery anodes. Siegal and Graham Yelton, a Sandia Labs Collaborator, showed the initial steps leading to practicable magnesium ion batteries that have a higher energy density when compared to lithium ion batteries. Batteries with higher energy density can be used to increase the operating distance of electric cars, improve the working time of cellphone batteries and also in satellites for performing longer missions. Katie Harrison, a Sandia Researcher, and Siegal have furthered their research by adding silicon to lithium-ion battery anodes, which can prospectively triple the energy storage density of the anodes.

Sandia’s Laboratory Directed Research and Development program funded the basic as well as the follow-up study by Siegal, Mowry and their respective colleagues.

Everybody who’s been involved with this project always smiles when they talk about it. Not only did we see our basic research into what this carbon material was and the physics of how SAW devices work come together, but we helped develop a successful product that improves public health.

Mike Siegal, Sandia Materials Scientist

Parker THM Analyzer

The analyzer was an R&D 100 Awards nominee in 2012.