Oct 24 2017

An innovative kind of stretchable and soft sensor can be employed in applications as wide ranging as health monitoring and athletics to virtual reality and prosthetics.

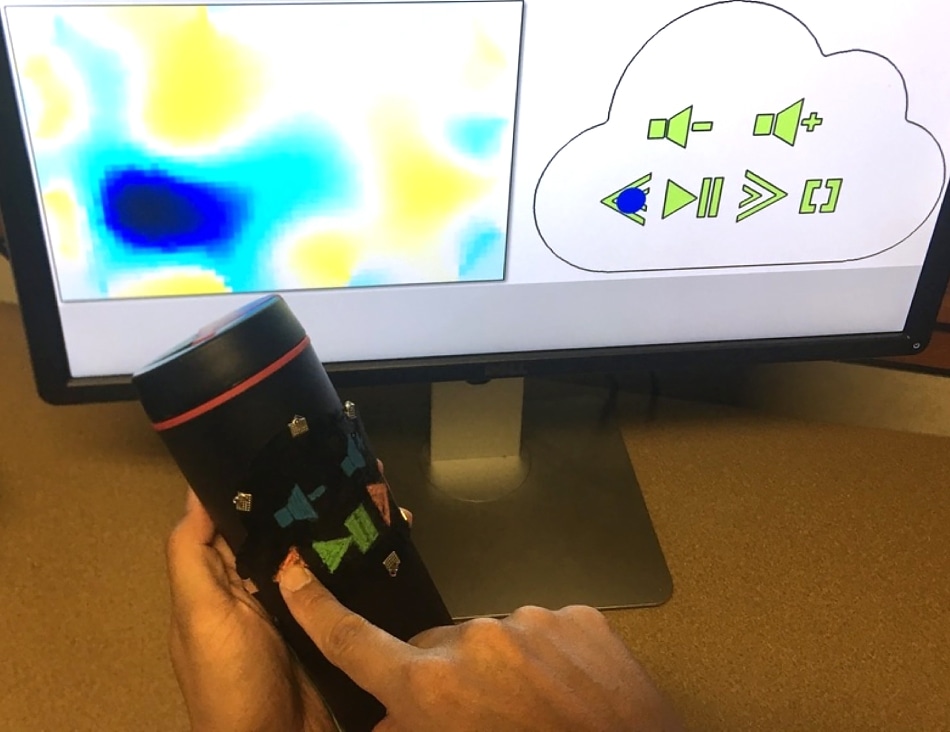

A new type of soft sensor developed at Purdue University can be attached to everyday objects including clothing. CREDIT: Purdue University image/C Design Lab.

A new type of soft sensor developed at Purdue University can be attached to everyday objects including clothing. CREDIT: Purdue University image/C Design Lab.

The technology known as iSoft has the potential to perform real-time sensing, perhaps without delay, and can carry out “multimodal” sensing, that is, sensing of a range of stimuli such as continuous contact stimuli stretching in all possible directions.

The novel part of iSoft is that it does not need any wiring or electronics within the material, the platform provides the ability to create and customize soft sensors. Even if you have no professional knowledge of electronics you can modify any object with it, including objects with complex shapes.

Karthik Ramani, Purdue University’s Donald W. Feddersen Professor of Mechanical Engineering and director of the C Design Lab

Wearable and flexible sensors such as these are being designed to evaluate and track body motion, which is a complicated task due to the innumerable possible distortions in the human anatomy. For a wearable sensor must function accurately, it has to have the ability to get appropriately deformed.

In contrast to certain soft sensors early designs, iSoft has the potential to handle continuous contact and can also be easily remodeled according to customised needs after being manufactured.

“By continuous, we mean moving on the surface and also pressing all the time such as drawing with a pen, which is difficult to achieve,” stated Ramani.

The sensor includes a “piezoresistive elastomer” that alters electrical resistance providing the sensing data, upon being touched.

“We are proposing a low-cost, easy way to fabricate such piezoresistive-elastomer-based soft sensors for instant interactions,” added Ramani.

The outcomes of the study have been reported in detail in a paper presented at the ACM Symposium on User Interface Software and Technology (UIST), from October 22 to 25, 2017, in Quebec City, Canada. Sang Ho Yoon, a Purdue doctoral student, will present the paper on October 25, 2017.

As indicated by the latest Levi’s jeans and a jacket that can connect with the Internet and other devices, wearable technologies, for example, “smart” garments are a surfacing market.

The iSoft platform is propitious for a range of applications such as health monitoring, tactile clothing as an interactive interface, artificial skin in robotics, and sports medicine.

The technology involves performing an electrical impedance tomography (EIT) method for evaluating alterations of resistance distribution on the sensor due to fingertip contact. The system also adopts an algorithm developed by the team known as a dynamic baseline update for EIT that acts as a counterbalance for “rebound elasticity,” which typically leads to a signal delay when the elastomer returns to its usual shape. Such baseline updates are initiated by detection of movement and fingertip contact.

Further, we support unidirectional stretching sensing using a model-based approach that works separately with continuous contact sensing, we also provide a software toolkit for users to design and deploy personalized interfaces with a customized look. This customization toolkit allows users to perform interactions instantly after deployment without any extra training processes.

Karthik Ramani, Purdue University’s Donald W. Feddersen Professor of Mechanical Engineering and director of the C Design Lab

The researchers performed a sequence of experiments and evaluations to validate the contact and stretching sensing performance.

A thin, rubbery sheet that has electrodes positioned along the periphery is used as the sensor. It is made of a material known as carbon-filled silicone rubber, which is a non-toxic piezoresistive material broadly investigated through analyses for producing different types of inexpensive sensors.

“However, the limitations in interactions have been mainly due to a rebound elasticity of the material, which causes a slow-recovery of the sensing signals after material deformations,” stated Ramani.

While the dynamic baseline update procedure overcomes the difficulty, the electrical impedance tomography method enables fabrication of sensors in a “single-volume manner,” that is, positioning electrodes on just the periphery of the material, thereby avoiding the use of invasive wires and sensors inside the material.

“We have verified the system accuracy and evaluated user performance. More immediately our work will benefit human computer interaction practitioners and novice makers who want to make their own functional soft sensors without in-depth knowledge of material processing or expensive fabrication equipment,” stated Ramani. “One can develop many future applications in wearables as well as make objects interactive, or it can be used with existing consumer products as a skin.”

Ramani, Yoon, doctoral student Ke Huo, postdoctoral research associate Yunbo Zhang, graduate student Guiming Chen, and doctoral students Luis Paredes and Subramanian Chidambaram were the authors of the paper.

The Purdue Research Foundation’s Office of Technology commercialization has filed a patent. The National Science Foundation, National Robotics Initiative, and an NSF IGERT grant in sustainable electronics partially supported the study.

Anything is a Controller: iSoft Makes Fabrics Interactive