Apr 11 2018

Observe the things hidden from the human eye. Retain the view during the failure of optical sensors. Radars render the invisible things visible. By making millimeter-waves to penetrate through textiles, wood, cardboard, and plastics, they observe the things behind walls, inside packaging, or behind fog and smoke.

Scientists at Fraunhofer IAF have capitalized the distinctive properties of millimeter-waves and have designed a compact W-band radar module that is perfectly suited for application in industrial sensors: It has the ability to screen packaged goods and provide precise information related to their contents. The Fraunhofer scientists will be demonstrating the application of this radar in an industrial environment from April 23 to 27 at the Hannover Messe at booth C22 in Hall 2, exhibiting their radar in the frame of the Research Fab Microelectronics Germany.

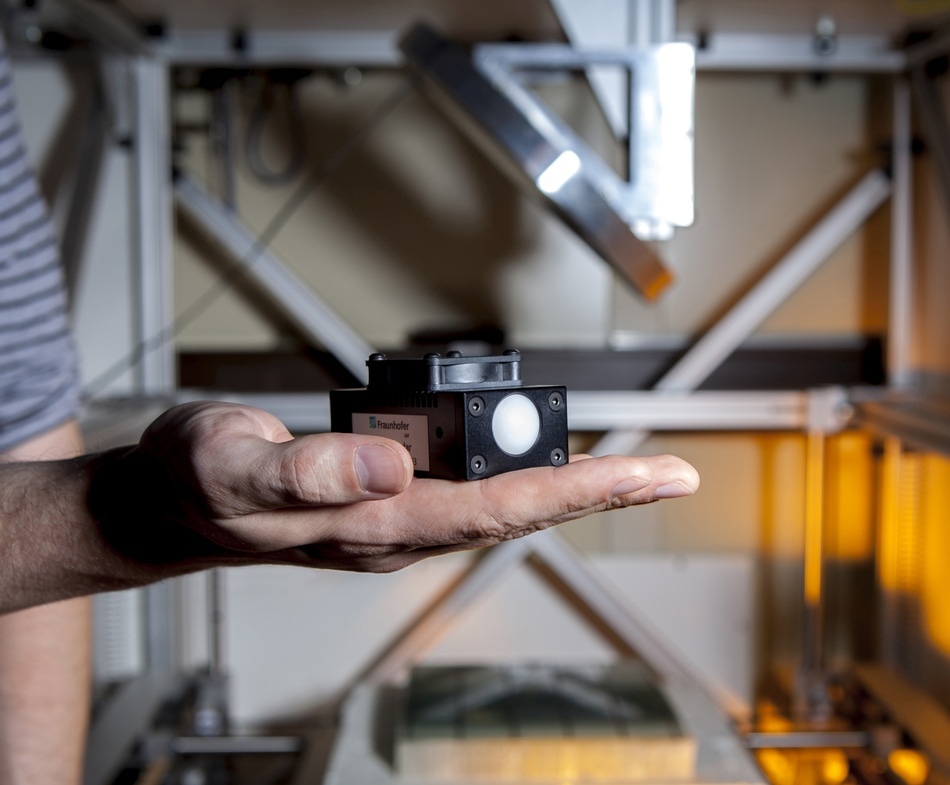

The compact W-band radar is about the size of a cigarette box. (Image credit: Fraunhofer IAF)

The compact W-band radar is about the size of a cigarette box. (Image credit: Fraunhofer IAF)

Modern industrial production has transformed to be highly self-reliant and self-organized with the use of digitally networked and intelligent systems: products, logistics, plants, machines, and people communicate and collaborate with each other and thus enhance individual production steps or even the complete value chain. This foresight of Industry 4.0 includes systems with the ability to make decisions independently based on the available data and perform tasks autonomously to the highest possible extent.

The W-band radar designed by the Fraunhofer Institute for Applied Solid State Physics IAF in Freiburg has advanced industrial automation to the next level. The radar examines packed goods for completeness and content. Depending upon the results, the system can automatically sort out faulty deliveries of goods prior to shipping.

The W-band radar designed at Fraunhofer IAF uses millimeter-waves at frequencies of 75–110 GHz, the so-called W-band. The emitted millimeter-waves penetrate all optically non-transparent and non-metallic materials such as wood, paper, textiles, plastic, or even fog, smoke, and dust.

Take a Look Inside

To date, optical sensors such as lasers have been chiefly used in the production process for presence detection. The drawback in using optical sensors is that lasers fail under conditions of poor visibility and cannot view behind packaging material. In contrast, apart from enabling high-precision distance measurements in fog, smoke, or dust, the W-band radar also provides a view behind objects and materials.

Similar to an X-ray machine that enables looking into the human body, the radar detects the things behind a wall or inside a package. However, unlike X-rays, the short-wave rays that the W-band radar emits in the millimeter range are not hazardous to the health of humans. Moreover, the radar’s transmission power is 100 times smaller when compared to that of a mobile phone.

The combination of the distinctive characteristics of millimeter-waves and the compact radar module designed by Fraunhofer IAF provides an extensive array of applications other than industrial sensors. “Radar can be used wherever contact-free material testing, control of packaged goods or high-precision distance measurements under difficult conditions such as restricted visibility are required,” stated Christian Zech, a scientist at Fraunhofer IAF. Various projects have already been launched by the institute, such as assistance for the safe landing of helicopters, the application of radar in the harsh environment of a steelwork, and safety aspects in human-machine interaction.

Precise, Compact, and Cost-Effective Technology

The radar’s operation is comparable to that of an echo. The signals emitted by the radar are reflected by objects and materials. Numerical algorithms are used to compare the transmit and receive signals, and information related to the things in front of the radar module and their distance is provided. “Despite their advantages, millimeter-wave radar systems have received little market acceptance so far, since low-frequency systems are too large and the production of high-frequency systems is too expensive,” explained Zech.

By contrast, the advanced design by the Fraunhofer scientists is modular, cost-efficient, and compact. Since the wavelengths are shorter and only around 3 mm, the size of the whole system is only about that of a cigarette box. The scientists have been successful in designing a cost-effective printed circuit board (PCB)-based assembly and interconnecting technology. “Our W-band radar is based on the semiconductor gallium arsenide, providing higher bandwidth, resolution, sensitivity, and ruggedness than radar systems operating on silicon circuits. This is crucial for many applications” explained Benjamin Baumann, an electrical engineer at Fraunhofer IAF.

Take a Look at the IAF Radar at the Hannover Messe

The scientists will be demonstrating the application of the W-band radar as one element of process automation at the Hannover Messe at the joint Fraunhofer stand in Hall 2, booth C22 in the frame of the Research Fab Microelectronics Germany. The display shows an industrial hall in which packaged goods are moved on production lines. The radar screens the packages that pass by and detects their contents. Incomplete or incorrect packaging is reported and instantly eliminated from the logistics chain.