Jul 30 2019

KIST President Byung-Gwon Lee informed that Dr Hyunjung Yi of the Post-Silicon Semiconductor Institute and her study group created a transfer-printing technology that uses hydrogel and nano ink to easily develop high-performance sensors on flexible substrates of various shapes and structures.

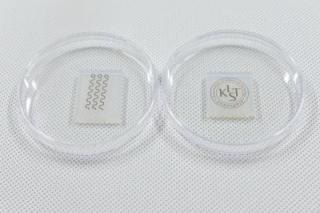

The real transfer-printing electrode that uses hydrogel and nano ink produced by Hyunjung Yi of the KIST’s Post-Silicon Semiconductor Institute. (Image credit: Korea Institute of Science and Technology (KIST))

The real transfer-printing electrode that uses hydrogel and nano ink produced by Hyunjung Yi of the KIST’s Post-Silicon Semiconductor Institute. (Image credit: Korea Institute of Science and Technology (KIST))

Wearable devices such as smartwatches and fitness bands are rapidly gaining a lot of interest. With the range of such devices growing from types that are worn like clothing to those that are adhered directly to the skin, there is increasing demand for technologies that permit the manufacture of high-performance sensors on surfaces of different types and shapes.

Transfer printing works quite like a tattoo sticker where the user sticks the tattoo sticker onto the skin and then peels off the paper section, leaving behind the image on the skin; this process forms a structure on a surface and then transfers it onto another.

The most prominent benefit of this process is that it mostly avoids the problems involved in developing devices directly on substrates that are chemically and/or thermally sensitive, which is why transfer printing is extensively used for making flexible devices. In contrast, the main drawback of present transfer printing methods is that they can mostly be used only for substrates with flat surfaces.

The KIST team sorted these limitations by creating a basic and easy transfer printing process that enables the making of high-performance, flexible sensors on topographic surfaces with varied textures and features.

The KIST team used the porous and hydrophilic nature of hydrogels to inkjet-print an aqueous solution-based nano ink onto a hydrogel layer (which was hardened onto a topographic surface). The surfactant and water in the nano ink passed rapidly via the hydrogel’s porous structure, leaving behind the hydrophobic nanomaterial (the particles of which are longer in length than the diameter of the holes in the hydrogel) on the surface, enabling the formation of the preferred electrode pattern.

The quantity of nano ink used for this printing process was really small, enabling the fast creation of electrodes. Furthermore, the electrical performance of the electrodes was exceptional because of the high levels of uniformity and purity of the resulting nanonetworks. Furthermore, due to the hydrophobic nature of the nanomaterial, there was a very low degree of interaction between it and the hydrogel, permitting the easy transfer of the electrodes to different topographic surfaces.

Particularly, the KIST team created a technology for shifting nanonetworks by employing a technique that hardens a moldable elastomeric fluid onto a hydrogel surface, allowing the easy creation of flexible electrodes even on substrates with rough surfaces. The team shifted nanoelectrodes straight onto a glove to produce a modified sensor that can instantly detect finger movements. It also produced a flexible, high-performance pressure sensor that can calculate the pulse in the wrist.

The outcome of this study is a new and easy method for creating flexible, high-performance sensors on surfaces with diverse characteristics and structures. We expect that this study will be utilized in the many areas that require the application of high-performance materials onto flexible and/or non-traditional substrates, including digital healthcare, intelligent human-machine interfaces, medical engineering, and next-generation electrical materials.

Dr Hyunjung Yi, Research Lead, Post-Silicon Semiconductor Institute