At Shenzhen University, fiber sensing scientists have built a small fiber optical nanomechanical probe (FONP) for quantifying in vivo biomechanical properties of tissue and also single cells.

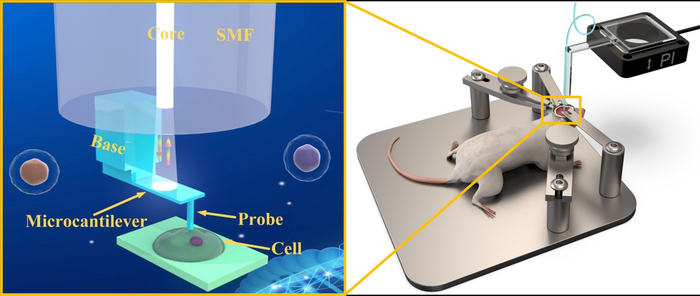

Fiber optical nanomechanical probe (FONP) fabricated by femtosecond laser two‐photon polymerization technology can realize the biomechanical measurement down to 2.1 nanonewton. Such high precision enables the measurement of in vivo biomechanical properties of tissue, single cell, and other soft biomaterials. Image Credit: By Mengqiang Zou, Changrui Liao, Yanping Chen, Lei Xu, Shuo Tang, Gaixia Xu, Ke Ma, Jiangtao Zhou, Zhihao Cai, Bozhe Li, Cong Zhao, Zhourui Xu, Yuanyuan Shen, Shen Liu, Ying Wang, Zongsong Gan, Hao Wang, Xuming Zhang, Sandor Kasas and Yiping Wang.

Scientists from Shenzhen University employed femtosecond laser-induced two‐photon polymerization technology to invent a fiber-tip microprobe having ultrahigh mechanical precision down to 2.1 nanonewtons.

The study has been published in the International Journal of Extreme Manufacturing journal.

This high-accuracy mechanical sensing system allows the measurement of in vivo biomechanical properties of a single cell, tissue, and other kinds of soft biomaterials. The outcomes could have an extensive effect on the future development of all-fiber Atomic Force Microscopy available for nanomanipulation and biomechanical testing.

The biomechanical properties of different tissues in the human body range widely with seven orders of magnitude, from the softest cells to the stiffest bones. We have developed a flexible strategy that could design and fabricate the fiber-tip microprobes with the most fitted spring constant for the accurate in vivo biomechanical measurement of almost all the tissues in the human body.

Yiping Wang, Study Lead Researcher and Professor, Boston College

Atomic Force Microscopy (AFM) is known to be one of the few technologies that could be capable of executing fragile biomechanical measurements. But, there are general limitations of the bench-top AFM system in its complex feedback system and size. Also, it needs a few geometries of the samples to be quantified, which additionally restricts its application in biomechanical measurement in vivo.

Our work achieved a new generation of all-fiber AFM with the flexible methodology to achieve the best design of the fiber-tip microprobe for every in vivo test, which was turned out to be reliable and also much more miniaturized.

Dr. Mengqiang Zou, Study First Author, Shenzhen University

Professor Changrui Liao has introduced the fiber-tip microdevices that have been fabricated by femtosecond laser-induced two-photon polymerization technology available for gas sensing.

This research group has come up with the technology to attain different fiber-tip microstructures, particularly microcantilevers with extra topological design, to obtain microprobes with a range of spring constants.

This development enables the so-called “all-fiber AFM” to turn into a next-generation tool for fundamental research involving the in vivo biomechanical measurement of several kinds of tissues.

The research group made use of the finite element technique and topological theory to improve the design of fiber-tip microcantilever probes. The finest microprobe has the potential to reach a trustworthy measuring capability down to 2.1 nanonewtons.

This is a milestone achievement and it is only the beginning. We anticipate this technique to become a powerful tool for in vivo biomechanical study of human tissue and cells, to further understand the fundamentals of biomechanical changes related with diseases such as cancer, and also in the critical processes of developmental biology.

Sandor Kasas, Professor, École polytechnique fédérale de Lausanne

Journal Reference

Zou, M., et al. (2023) 3D printed fiber-optic nanomechanical bioprobe. International Journal of Extreme Manufacturing. doi.org/10.1088/2631-7990/acb741.