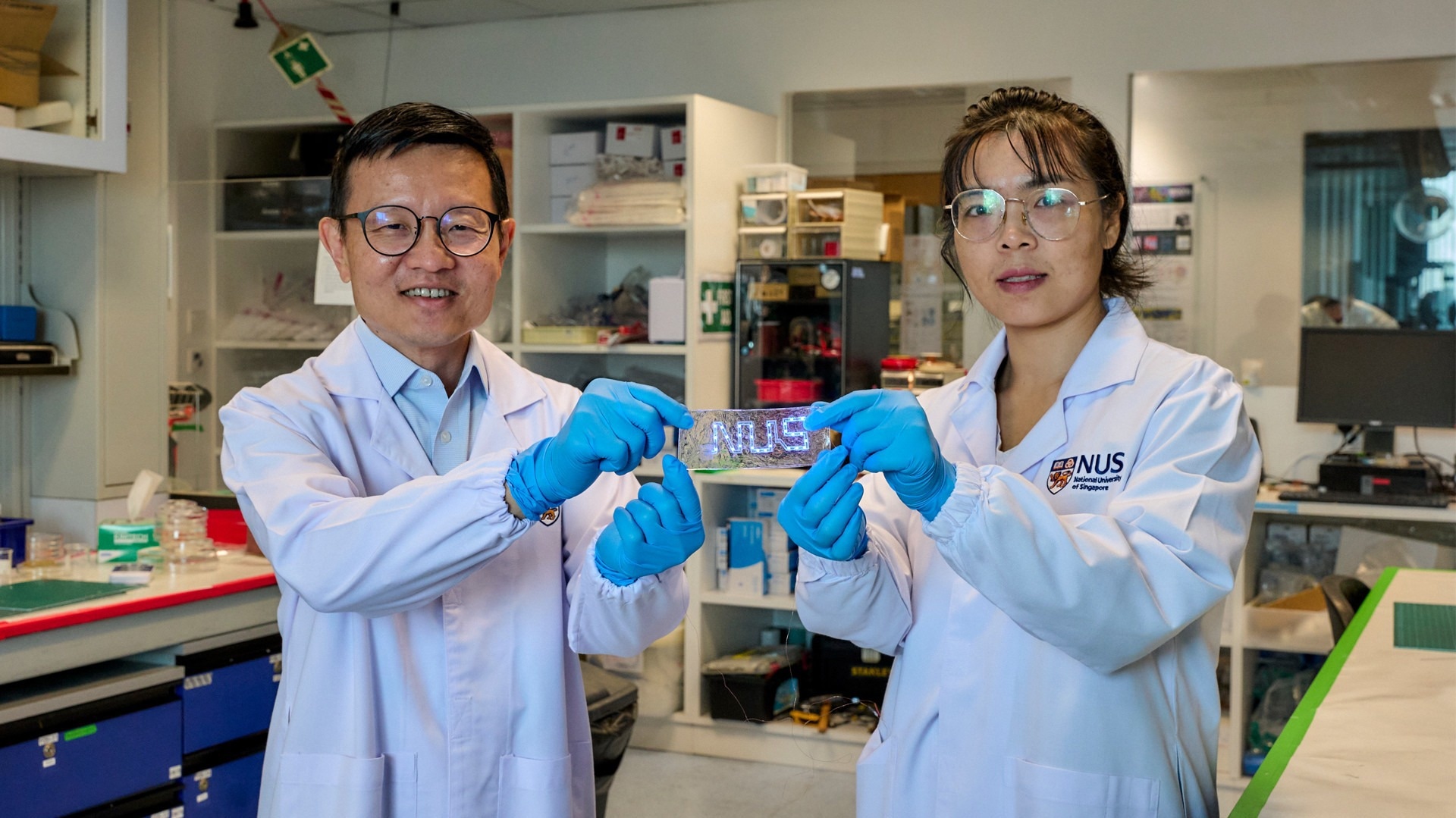

Prof Lim Chwee Teck (left), Dr Chen Shuwen (right) and their team have developed a novel liquid-metal material (held by the researchers) suitable for making flexible and unbreakable circuitry for stretchable electronics. Image Credit: National University of Singapore

The newly developed material, known as the Bilayer Liquid-Solid Conductor (BiLiSC), can be stretched up to 22 times its original length without losing substantial electrical conductivity.

This hitherto unseen electrical-mechano characteristic improves the comfort and efficacy of the human-device interaction and offers up a wide range of possibilities for its usage in healthcare wearables and other applications.

We developed this technology in response to the need for circuitry with robust performance, functionality and yet ‘unbreakable’ for next-generation wearable, robotic and smart devices. The liquid metal circuitry using BiLiSC allows these devices to withstand large deformation and even self-heal to ensure electronic and functional integrity.

Lim Chwee Teck, Study Lead and Director, Institute for Health Innovation & Technology, National University of Singapore

Prof Lim and his colleagues are also from the NUS College of Design and Engineering’s Department of Biomedical Engineering.

Flexible, Self-Healing and Conductive ‘Super Material’

The innovative technology known as BiLiSC is perfect for use in wearable gadgets that must take into consideration the form and complex motions of the human body.

There are two levels to it. A self-assembling pure liquid metal makes up the first layer. It can maintain high conductivity even when put under stress, which lowers energy loss during power transfer and signal loss during signal transmission.

The second layer is made of a composite material that can self-heal after breaking and contains liquid metal microparticles. The liquid metal coming out from the microparticle can pass into the space created by a crack or tear, allowing the material to virtually instantly mend itself and maintain its high conductivity.

The NUS team discovered a method to construct BiLiSC in a highly scalable and cost-effective manner to make sure the discovery is commercially feasible.

In November 2022, Advanced Materials reported on this technical advance.

High Performance and Multifunctional

The NUS team revealed that BiLiSC could be converted into a variety of electrical components of wearable electronics, including pressure sensors, interconnections, wearable heaters, and wireless communication.

In laboratory tests, a robotic arm with interconnectivity detected and responded to minute changes in pressure faster. Furthermore, as compared to another interconnection built using a non-BiLiSC material, the bending and twisting motion of the robotic arm did not inhibit signal transmission from the sensor to the signal processing unit.

Next Steps

The NUS team is now focusing on material innovation and process fabrication following the successful display of BiLiSC. They are trying to develop a better version of BiLiS that can be printed straight away without a template. This would lower the cost and increase the accuracy of the BiLiSC fabrication process.

Journal Reference

Chen, S., et al. (2023) Ultrahigh Strain-Insensitive Integrated Hybrid Electronics Using Highly Stretchable Bilayer Liquid Metal Based Conductor. Advanced Materials. doi:10.1002/adma.202208569