Human skin has over 1,000 nerve endings, making it the brain’s most significant sensory organ connected to the external environment. Touch, pressure, and temperature all provide a variety of feedback. Skin is an essential organ because of its intricate properties, which also make it difficult to reproduce.

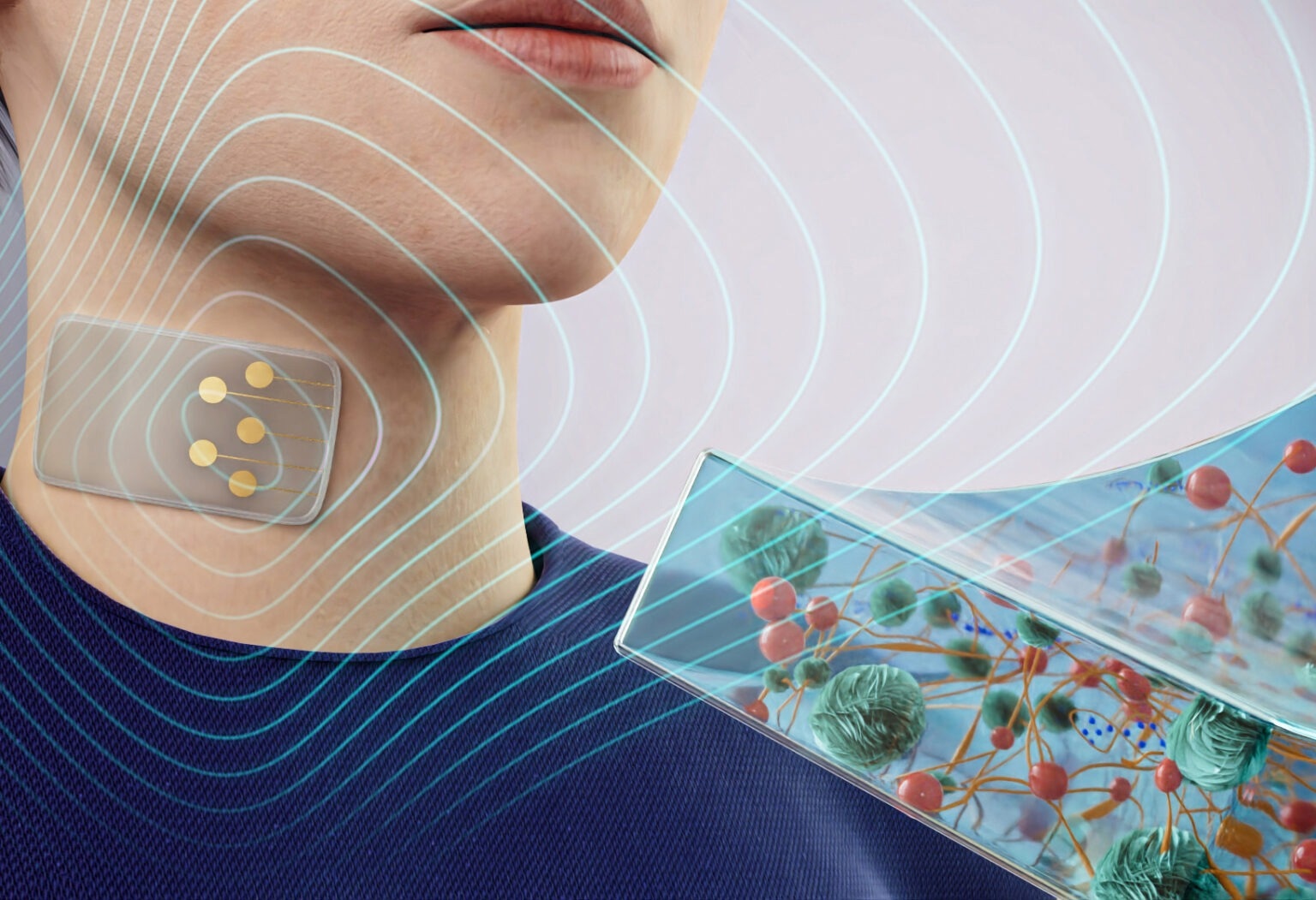

Future uses for the E-skin include wearable health devices that continuously monitor vital signs like motion, temperature, heart rate and blood pressure. Image Credit: INMYWORK Studio

A 3D-printed electronic skin (E-skin) that can stretch, flex, and sense like human skin has been created by Texas A&M University researchers using nanoengineered hydrogels that have programmable electrical and thermal biosensing capabilities.

The ability to replicate the sense of touch and integrate it into various technologies opens up new possibilities for human-machine interaction and advanced sensory experiences. It can potentially revolutionize industries and improve the quality of life for individuals with disabilities.

Dr. Akhilesh Gaharwar, Professor and Director of Research, Department of Biomedical Engineering, Texas A&M University

The E-skin has numerous additional uses in store, such as wearable medical devices that track vital indicators like blood pressure, heart rate, motion, and temperature constantly and provide users feedback to help them get better at motor skills and coordination.

Dr. Gaharwar added, “The inspiration behind developing E-skin is rooted in the desire to create more advanced and versatile interfaces between technology, the human body and the environment. The most exciting aspect of this research is its potential applications in robotics, prosthetics, wearable technology, sports and fitness, security systems and entertainment devices.”

Gaharwar’s lab invented the E-skin technology, which is described in a study published by Advanced Functional Materials. The study’s lead authors are Dr. Kaivalya Deo ‘22, a former student of Gaharwar who is currently employed as a scientist at Axent Biosciences, and Dr. Shounak Roy, a former Fulbright Nehru doctoral fellow in Gaharwar’s lab.

Stiff Challenges

The development of robust materials that can replicate the flexibility of human skin while also having bioelectrical sensing capabilities and using manufacturing processes appropriate for wearable or implantable devices are hurdles in the process of creating E-skin.

In the past, the stiffness of these systems was too high for our body tissues.

Dr. Kaivalya Deo, Scientist, Axent Biosciences

The constraint was overcome by the team’s nanoengineered hydrogel-based system since hydrogels can decrease viscosity under shear stress during the production of E-skin, making handling and manipulation simpler. According to scientists, this property makes it easier to build intricate 2D and 3D electronic structures, which is crucial for simulating the complex construction of human skin.

Additionally, the researchers used nanoparticles to aid in the E-skin's adhesion to moist tissue and a material with atomic structural flaws that permit significant electrical conductivity. The hydrogel and nanoparticles form a connection that gives the E-skin electrical and thermal conductivity.

We are the first to report using this as the key component. The material’s ability for adhesion to wet tissues is particularly crucial for potential healthcare applications where the E-skin needs to conform and adhere to dynamic, moist biological surfaces.

Dr. Shounak Roy, Postdoctoral Fellow, Technion - Israel Institute of Technology

Researchers from the groups of Dr. Limei Tian at Texas A&M's biomedical engineering department and Dr Amit Jaiswal at the Indian Institute of Technology, Mandi are additional collaborators. The United States-India Educational Foundation, the Department of Defense, and the National Institutes of Health are the study’s sponsors.

Journal Reference

Roy, S., et. al. (2024) 3D Printed Electronic Skin for Strain, Pressure and Temperature Sensing. Advanced Functional Materials. doi:10.1002/adfm.202313575