A research team at KAUST has developed a highly sensitive, passive wireless strain sensor that is thin enough to be embedded within structures without causing defects. The study was published in Advanced Science.

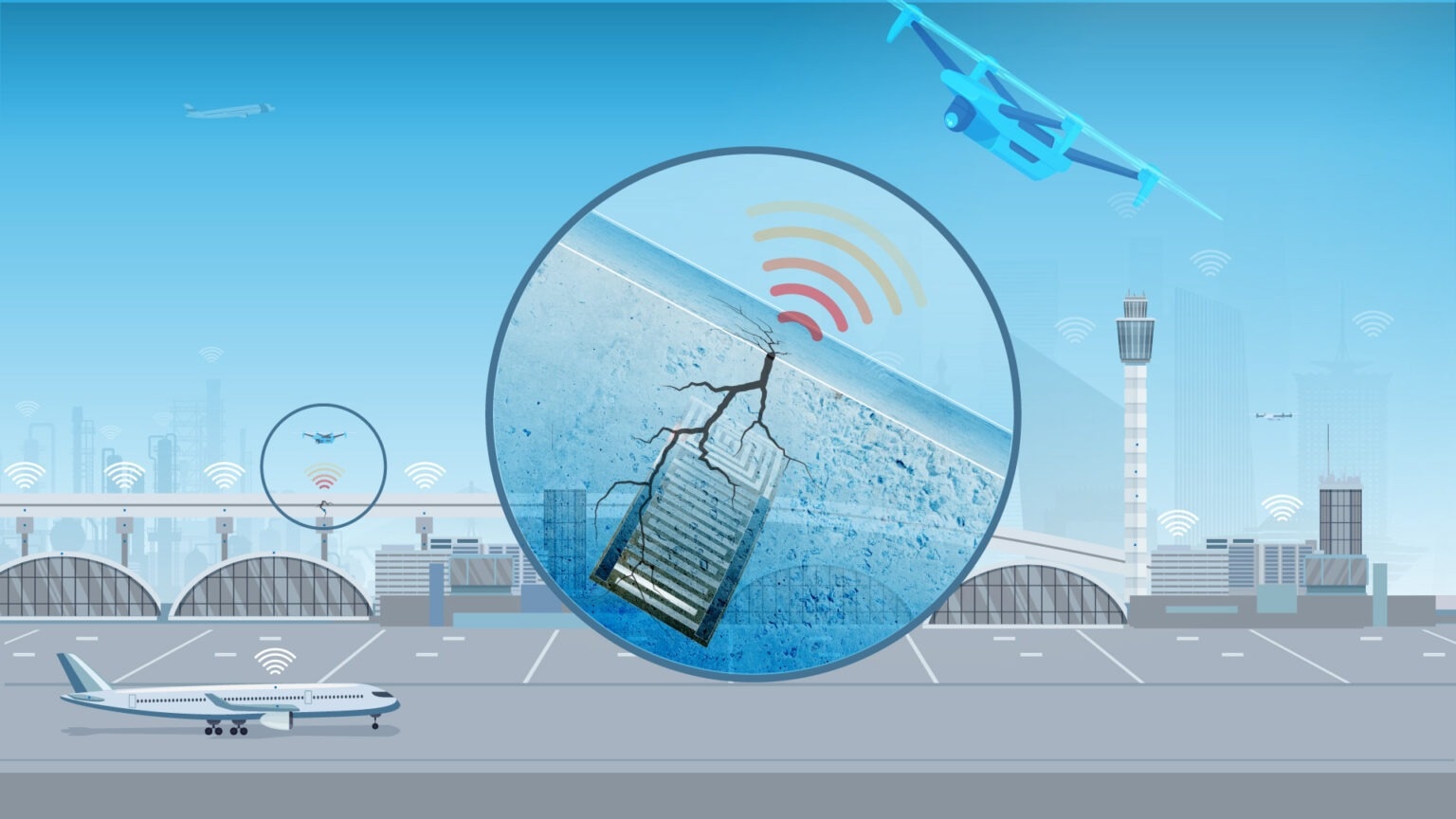

KAUST researchers have developed an ultra-sensitive wireless strain sensor with versatile applications, from industrial uses such as aerospace structures, oil and gas rigs, and bridges to monitoring health indicators. Image Credit: ©2025 KAUST.

KAUST researchers have developed an ultra-sensitive wireless strain sensor with versatile applications, from industrial uses such as aerospace structures, oil and gas rigs, and bridges to monitoring health indicators. Image Credit: ©2025 KAUST.

With further development, the KAUST team anticipates that the chipless design could be adapted to detect other stimuli, such as temperature or chemical changes.

The design efficiently integrates multiple existing technologies into a single, effective solution.

The advantage in terms of sensitivity comes from merging different physics for two different responses from two materials.

Hassan Mahmoud, Doctoral Researcher, King Abdullah University of Science and Technology

Gilles Lubineau headed the study.

The sensor is printed using inks that alter their electrical resistance in response to strain. These inks form a circuit with capacitive domains, allowing the sensor to be wirelessly activated at a specific frequency. The circuit is engineered to ensure the activation frequency is highly responsive to stimulation and accurately reflects the strain experienced by the sensor.

The manufacturing process for this sensor is expected to be quick and straightforward.

Our mechanism uses simple available materials and techniques, so it is suitable and scalable for use by industry.

Hassan Mahmoud, Doctoral Researcher, King Abdullah University of Science and Technology

The design may require adjustments based on specific use cases, but Mahmoud does not anticipate this being a significant challenge. “The R&D is done, so it is just about customizing it to be suitable to the application, like using a substrate that’s right for wearables or that can withstand the high temperatures in structural manufacturing,” he notes.

A mechanical engineer, Mahmoud explains that the sensor was developed to address an engineers' needs. “We have lots of challenges when it comes to inspecting or monitoring structures during operations, especially with composite materials, which are very sensitive to having sensors embedded,” he adds. However, the new sensor is thin enough to be integrated into composites.

He envisions a broad range of potential applications.

It can be used in industrial applications, such as aerospace structures, oil and gas rigs, and many other structures that need real-time monitoring, like bridges. The technology can also be used for wearables, for example, to monitor the movement of muscles in sports or to track relevant health indicators.

Hassan Mahmoud, Doctoral Researcher, King Abdullah University of Science and Technology

Lubineau highlights how further development could expand its applicability even further. “With additional research, we can tune the architecture that we invented to design sensors for other types of stimuli, like the chemical environment. We can build a full portfolio of sensors using the same physical principles,” he details.

Journal Reference:

Mahmoud, H. A., et al. (2025) A Fully Printable Strain Sensor Enabling Highly‐Sensitive Wireless Near‐Field Interrogation. Advanced Science. doi.org/10.1002/advs.202411346.