Rowe Hankins, a specialist in wheel flange lubrication systems, has launched the iWFL (Intelligent Wheel Flange Lubrication). The lubrication system is capable of reducing noise while negotiating tight curves that are found at urban tramways and station entrances.

The iWFL benefits rail network companies as it reduces the track wear to a great extent and hence eliminates the need for costly maintenance systems.

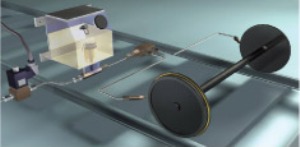

The iWFL uses water-based, eco-friendly and lightweight lubricants. It comes as a comprehensive package with sensors for detecting speed and distance that are aligned with the global positioning system, a gyroscope for tilt detection and transponders that help in locating the track sections that need lubrication.

iWFL

iWFL

The iWFL can easily be fitted to the existing rolling stock and the control options can be adjusted as per the user’s needs. In case of using the iWFL on underground trains, the GPS is replaced by a transponder to supply data to the control unit to calculate the time and distance to the curve. The speed and distance are calculated based on Hall-effect.

At the Railtex, Rowe Hankins will also display the NIC361 Series Monitor that can be used for non-intrusive monitoring of DC Current and can be used in vehicles to guard against reversal of polarity. The unit’s output signals can be set up to provide visual indication, capture or disrupt based on the event.

The UK rail industry has benefited greatly by the Eaton Hydraulic magnetic circuit breakers from Rowe Hankins. These circuit breakers exhibit tolerance to extreme temperatures, vibration and dust and also have a unique characteristic to tell the difference between transient conditions and genuine hazards. They come with electrical protection, which guarantees protection from earth leakage. The circuit can be tripped or reset by an easy-to-use push button mechanism. Apart from the above products, Rowe Hankins intends to show the on-train monitoring and recording equipment from HaslerRail.