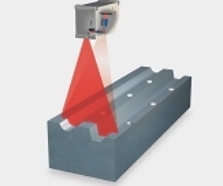

BESTECH Australia has introduced a new laser profile scanner, which not only measures but also evaluates complex 2D and 3D products. For 2D profile measurement on different target surfaces, the Micro-Epsilon LLT 2710 laser profile sensor makes use of laser triangulation.

It utilizes a special lens and from it a laser beam is magnified to form a static laser line, which then gets projected on the surface of the target.

Micro-Epsilon LLT 2710

Micro-Epsilon LLT 2710

The optical system in the sensor projects the reflected diffused light of the laser line on a sensitive sensor matrix, and the controller then makes use of the distance information denoted by the z-axis and the profile image to determine the position along the laser line i.e. x-axis. These measurements are then plotted in a 2D coordinate system.

3D objects or targets could also be measured if the laser scanner is passed over the target directly or if the target is in motion. The LLT 2710 laser scanner is being used in several applications, including automotive, building products, heavy engineering and electrical component manufacturing industries. It is also utilized by the robotics industry to position the robotic hands precisely for pick and place functions and also for extruding thin glue lines on printed circuit boards.

This sensor, being self-contained, can work either in standalone mode or with a host personal computer. The data is then sent via Ethernet interfaces or RS422 or through FireWire with HUB.

Profile frequency is 2000 Hz maximum, while the measuring rate is 1,280,000 points/second maximum. The measurement range for the x axis is 148 mm with 640 point resolution maximum, while for the Z axis the maximum measurement range is 300 mm with <4 µm resolution.