Nov 16 2012

Wireless sensor networks monitor machinery and equipment in factories, cars and power stations. They increasingly “harvest” the energy they need to transmit measurement data from the environment, thus making them self-sufficient. At the Electronica 2012 trade fair, Fraunhofer researchers will present a printed thermogenerator, which in the future will be able to generate energy supply for sensors through temperature differences.

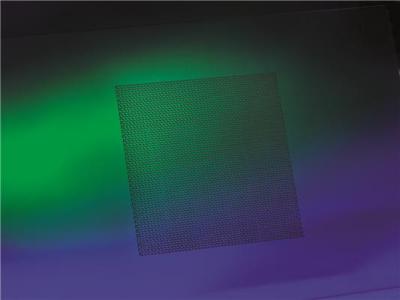

A targeted combination of thermoelectrical and metallic materials enables structures to be printed and used as thermoelectrical generators. (c) IFAM

A targeted combination of thermoelectrical and metallic materials enables structures to be printed and used as thermoelectrical generators. (c) IFAM

The computer activates an alarm: the machine’s motor is threatening to overheat. The thermosensor attached directly to the motor housing reports the threat. The information is transmitted to the maintenance service which ensures that the cause is identified. Sensors can be used in factories, car manufacturers and other areas in everyday life. They measure temperature, humidity and wear and tear. Data is transmitted to the computer via wireless communication and read out. This enables the provision of information on the condition of parts – for instance, whether maintenance or repairs are required. More and more frequently wireless sensors are used which consume very low levels of energy and the power required by the sensor, the processing unit and wireless module derives its power directly from the environment instead of “harvesting” energy from batteries Electrical energy can be generated, for instance, from heat or movement. Researchers from the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM in Bremen will be presenting a printed thermogenerator, which can be tailored exactly to technical interfaces, at the Electronica trade fair in Munich (13 – 16 November) Hall A5, Booth 121.

Monitoring with energy-autonomous sensors

“Wireless sensor networks facilitate the monitoring of safety-related components”, explains Dr. Volker Zöllmer, Head of Functional Structures, whose work focuses on the topic of Energy Harvesting at the Fraunhofer IFAM. For sensors to work at optimum capacity, they must be attached directly to the component’s interface or even integrated into the component. The power supply is usually obtained via cable or battery. “However, the limited storage capacity and battery life, as well as the issue of recycling, are critical subjects for the user”, appreciates Zöllmer. “In our experience, a replaceable battery contributes significantly to the design of an application and as such restricts the flexible layout”.

To ensure that the sensor network is entirely suitable for energy supply by means of energy harvesting, it must only consume low levels of energy. If sensors in intelligent networks are only active when sending and receiving data, energy is only required in milliwatts. Thermogenerators can deliver these quantities, for example, converting ambient heat into power. The IFAM researchers use new production processes to custom manufacture such generators.

Printing thermogenerators

“Generative manufacturing processes produce both sensors and sensor networks as well as the required elements for energy harvesting such as thermogenerators: By directly depositing functional structures, which have an ink or paste base, using ink-jet, aerosol-jet, screen-printing or dispensing processes, not only can electrical circuit boards and sensor elements be attached to different interfaces but it is also possible to produce structures which harvest energy”, explains Zöllmer. Using a purposeful combination of metallic and thermoelectrical materials which are successively applied, the researchers manufacture structures which can be used as thermoelectrical generators. The major advantage of this is that the printed thermogenerators can be tailored exactly to the technical surfaces. This makes the sensors less susceptible to faults because the energy supply can be adapted directly to the respective requirements.