Kistler Instruments will be demonstrating the benefits of its CoMo Injection including MultiFlow automatic hot runner balancing systems at the free, one day seminar being held on 2nd April 2014 at the Polymer Training & Innovation Centre in Telford.

The seminar will be of special interest to injection moulding and automation managers, engineers, technicians, setters, maintenance engineers, QA personnel and mould designers.

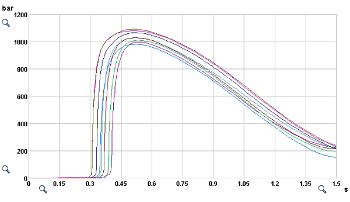

The CoMo Injection system increases productivity and minimises rejects by using cavity pressure to monitor and control the injection moulding process. The MultiFlow system automatically controls hot runner tip temperatures to synchronize all pressure profiles. This approach stabilizes the process and balances batch variations as well as ambient effects and other interferences.

In addition to the Kistler demonstration, the day will include presentations and demonstrations from other leading manufacturers of equipment for the injection moulding industry.

The all-day seminar, including lunch, is free but places are limited. To reserve a place, contact Claire Cooper on 01952 610101 or email [email protected].

About the Kistler Group

The Swiss-based Kistler Group is a leading global supplier of dynamic measurement technology for pressure, force, torque and acceleration. Kistler’s technology is used to analyse physical processes, control industrial processes and optimize product quality.

Kistler has a full range of sensors, electronics and systems for engine development, vehicle technology, assembly technology, plastic and metal processing as well as for biomechanics.

The Group maintains its global presence through 28 sales and manufacturing companies, with tech centres on all continents and more than 30 agencies, enabling the Group to maintain local contact with customers and offer individualized application support.

The Kistler Group employs 1,200 people and generated revenues of CHF 279 million (GBP 193M) in 2012.