The new Type 8152C Piezotron® sensor is ideal for monitoring acoustic emissions (AE) above 50 kHz on the surface of metal machines, structures and systems for preventative maintenance of rotating machines, monitoring cutting tools and press tools to detect signs of incipient failure and leakage monitoring of tanks, pipes and valves.

The rugged welded housing, wide operating temperature range from -54°C to 165°C and IP65 rating make the new sensor suitable for use in the most challenging industrial environments. ATEX Zone 0 and Zone 2 intrinsically safe versions are available for use in hazardous areas. Two frequency ranges, 50 to 400 kHz and 100 to 900 kHz, are offered in all versions. An integrated impedance converter provides a low impedance voltage output signal and a custom designed coupler supplies power to the sensor and provides signal processing.

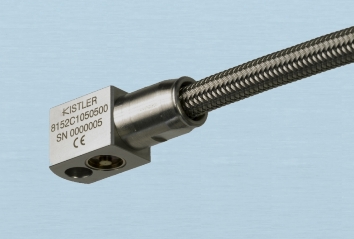

Type 8152C Piezotron® sensor.

Type 8152C Piezotron® sensor.

The AE Sensor is simply mounted with an M6 or ¼ inch screw or a magnetic clamp onto the surface of the structure. The sensing element is acoustically isolated from the housing by design and is well protected against external noise and is ground isolated to prevent ground loops. Kistler AE sensors feature a very high sensitivity for surface (Rayleigh) and longitudinal waves over a broad frequency range and are designed to withstand high energy waves.

These new sensors provide a simple to install and highly reliable method of monitoring bearing based machinery, pressure vessels or flow turbulence with high frequency acoustic signatures. AE measuring can be used where vibration sensors are unsuitable due to the high energy nature of the emitted elastic waves.

It also allows the reliable detection of fatigue and failure signals even in a high vibration environment. The measuring chain may be used for non-destructive testing or permanent online observation of continuous processes for condition monitoring and preventive maintenance applications. The high operating temperature of 165ºC and ATEX certifications option allows use in hazardous environments, such as processing industry applications where explosive gas or flammable dust is present.

Kistler Group

The Swiss-based Kistler Group is a leading global supplier of dynamic measurement technology for pressure, force, torque and acceleration. Kistler’s technology is used to analyse physical processes, control industrial processes and optimize product quality.

Kistler has a full range of sensors, electronics and systems for engine development, vehicle technology, assembly technology, plastic and metal processing as well as for biomechanics.

The Group maintains its global presence through 26 sales and manufacturing companies, with tech centres on all continents and more than 30 agencies, enabling the Group to maintain local contact with customers and offer individualized application support.

The Kistler Group employs 1,250 people worldwide and generated revenues of CHF 285 million (GBP 193.5M) in 2013.