World leading manufacturer of resistance welding technology, Sciaky Electric Welding Machines Ltd, is using Kistler piezoelectric strain sensors to meet the demands of the aerospace industry for the precise monitoring of the welding process.

The Kistler strain sensors are easier to fit, simpler to replace, more reliable and longer lasting than the load cells previously used.

With experience spread over 80 years and an impressive worldwide customer list, which includes most of the leading automobile and aerospace companies, Slough-based Sciaky has led the way in the development of resistance welding, especially of “difficult” materials. In particular, aerospace applications, where very clean aluminium and titanium are welded, demand reliable monitoring of the welding process.

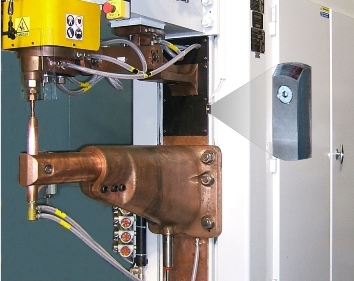

A critical parameter is the force exerted by the welding electrodes, which was previously measured by a load cell installed inside the ram connecting the weld cylinder to the electrode control mechanism. This required special machining and significant dismantling when replacement was needed. By contrast, the Kistler piezoelectric strain sensor, mounted externally on the main structure of the machine, requires only simple machining to provide a flat seating and a single tapped hole for mounting the sensor.

Unlike the load cell, the piezoelectric strain sensor measures the force at the electrodes indirectly by reference to the strain on the main body of the machine. The conversion from strain to force is achieved using a Kistler Type 5073A single channel industrial charge amplifier which is mounted on the machine remotely from the sensor.

In addition to fitting the sensors to new welding machines, Sciaky now retrofit the Kistler strain sensor whenever the old-style load cell needs replacing. According to Sciaky Managing Director, Louis Kunzig, the strain sensor is now fitted as standard to all Sciaky Resistance welding machines supplied for aerospace applications and for critical applications, such as manufacturing steering components, in the automobile industry.

Kistler Group

The Swiss-based Kistler Group is a leading global supplier of dynamic measurement technology for pressure, force, torque and acceleration. Kistler’s technology is used to analyse physical processes, control industrial processes and optimize product quality.

Kistler has a full range of sensors, electronics and systems for engine development, vehicle technology, assembly technology, plastic and metal processing as well as for biomechanics.

The Group maintains its global presence through 26 sales and manufacturing companies, with tech centres on all continents and more than 30 agencies, enabling the Group to maintain local contact with customers and offer individualized application support.

The Kistler Group employs 1,250 people worldwide and generated revenues of CHF 285 million (GBP 193.5M) in 2013.