Apr 9 2014

The German Federal Environmental Foundation (Deutsche Bundesstiftung Umwelt) announces the launch of a groundbreaking project for which the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) is developing sophisticated measuring sensors.

The aim is to supply oxygen more efficiently to the microbes that are used in biological treatment stages. Such efficiency speeds up the purification process and saves energy. In addition to HZDR and the TU Dortmund University, three partners from the industrial sector are also participating in the project.

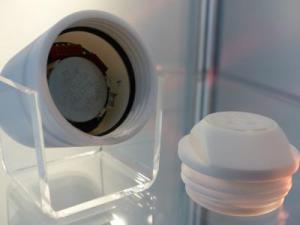

Autonomous sensors measure complex flows in what are known as aerated tanks. These sensors assist in making energy-intensive wastewater treatment processes more efficient. Credit: HZDR

Autonomous sensors measure complex flows in what are known as aerated tanks. These sensors assist in making energy-intensive wastewater treatment processes more efficient. Credit: HZDR

The sensors developed by the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) float like toy submarines through the turbid mixture. Every twenty seconds the sensors measure the ambient pressure, the temperature and, using an acceleration sensor, the direction and strength at which they are tossed back and forth by the flow in the treatment plant's basin. This data helps scientists determine how well wastewater is mixed and how well the bacteria contained within it are supplied with oxygen. In a pilot program sponsored by the German Federal Environmental Foundation (DBU), this smart measurement method is to be utilized for the first time in existing wastewater treatment plants.

In what are known as aeration tanks, microbes break down organic waste products in our wastewater, a process for which oxygen is required. The treatment plants, therefore, inject air into the sludge from below and thoroughly mix all the material. This process requires quite a lot of energy and is a primary reason why the handling of wastewater is one of the greatest energy consumers within municipal areas. The UN, for example, estimates that approximately eight percent of annual energy use worldwide goes to the handling and transport of water and wastewater. Because of growing financial pressures, municipalities are, therefore, making considerable efforts to improve this process.

But the precise manner in which air bubbles in wastewater move and are distributed is unknown; some zones are often amply supplied, while others still suffer from a lack of oxygen. The microbes cannot effectively work in such areas. In order to err on the side of caution, treatment plants prefer to mix and aerate too much rather than too little, which unnecessarily eats up a great deal of energy. The costs also rise in proportion with energy usage.

A working group at the Helmholtz-Zentrum Dresden-Rossendorf has now developed something like small "submarines." They look somewhat like the plastic containers from "Kinder-Surprise" eggs – but are somewhat larger and white in color. "Sebastian Reinecke, our recent PhD graduate, had initially developed them for bioreactors," says Uwe Hampel, AREVA Endowed Chair of Imaging Techniques in Energy and Process Engineering at the Technische Universität Dresden as well as department head at the HZDR Institute of Fluid Dynamics.

These battery-powered sensors are watertight and are added to the wastewater. Because the scientists make the sensors precisely the same weight as the wastewater that they displace, the sensors float around and follow the flow. The researchers fish the instrument from the tank after some time and retrieve the data. Using these data, they can determine the dynamic of the flow and can integrate this knowledge more precisely into numerical flow simulations and subsequently inform the treatment plants on how strongly they should mix. Professor Peter Ehrhard's working group at the TU Dortmund is in charge of the computer simulations, which in scientific jargon are called "Computational Fluid Dynamics." Hampel says, "For the next step, we want to equip the sensors so that they can be located – and their data can be retrieved – from outside the tank." This great idea is not only exciting for wastewater experts. The Helmholtz engineers have already received an innovation prize at the energy trade fair "enertec" for the automated sensor technology they developed for biogas plants.

The Air Bubble Riddle

It sounds astonishing, but we still do not understand exactly how an air bubble moves through a fluid – and we know even less about this process when a bubble deforms in water, when it dissolves in the fluid or combines with other bubbles. "With the help of our self-developed X-ray tomograph, we would like to investigate this topic with precision in a laboratory," explains Hampel. With a speed of up to 10,000 frames per second, the tomograph makes deep insights and panoramic views possible – even in the murkiest soup, and in 3-D.

One aim of the project is to increase the amount of oxygen absorbed by the wastewater, as the bubbles rise, from the current rate of about twelve percent per meter to well over twenty percent. The researchers from HZDR and TU Dortmund also want to investigate whether the waste treatment plants can dispense with all mixers. Thorough mixing can then be achieved exclusively by the air injected into the basin as well by using an adjusted geometry of the basin, which can be, for example, additionally equipped with sheet metal.

"The ideas are not new," Hampel explains, "but no one has so far been able to simulate what the suggested innovations might bring, if anything at all." In addition, new needle aerators produced by the firm IWEB are now in use within the framework of this project. Using these in combination with modern measuring techniques and computer simulations, oxygen injection can be achieved to a level of demand-oriented precision, which has not been accomplished in the past.

In addition to the Helmholtz-Zentrum Dresden-Rossendorf (HZDR), the consortium consists of the Institute for Water & Energy Bochum GmbH (IWEB), TU Dortmund, Süd-Oberlausitzer Water Supply and Wastewater GmbH and the Ruhrverband AG. The consortium partners have requested nearly EUR 370,000 for the project, of which approximately EUR 160,000 would go to HZDR. The duration of the project is three years. The funding for the first year has now been granted in the amount of nearly EUR 140,000 (including EUR 55,600 for HZDR).