Jun 24 2014

Many creatures in nature, including butterflies, newts and mole rats, use the Earth's inherent magnetic field lines and field intensity variations to determine their geographical position.

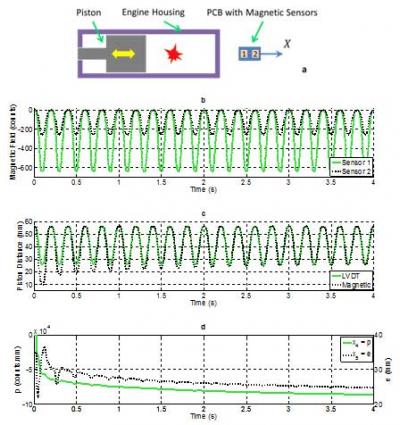

(a) Two axially spaced magnetic sensors are used. (b) The raw magnetic field signals measured by sensors 1 and 2 due to the piston's inherent magnetic field are shown (c) Position estimates from the magnetic sensor and comparison with a LVDT reference sensor are shown. (d) The system does not require pre-calibration and automatically computes algorithm parameters for each individual piston-cylinder combination. (Credit: Authors)

(a) Two axially spaced magnetic sensors are used. (b) The raw magnetic field signals measured by sensors 1 and 2 due to the piston's inherent magnetic field are shown (c) Position estimates from the magnetic sensor and comparison with a LVDT reference sensor are shown. (d) The system does not require pre-calibration and automatically computes algorithm parameters for each individual piston-cylinder combination. (Credit: Authors)

A research team at the University of Minnesota has shown that the inherent magnetic fields of ferromagnetic objects can be similarly exploited for accurate position measurements of these objects. Such position measurement is enabled in this research by showing that the spatial variation of magnetic field around an object can be modeled using just the geometry of the object under consideration. Using this model of magnetic field variation with position and measuring the magnetic field at the sensor's location, the position of the ferromagnetic object is calculated.

A significant challenge is posed by the fact that the parameters of the model would vary from one object to another, even for objects of the same shape. This challenge is addressed by the use of redundant sensors with known inter-sensor distances and associated adaptive estimation algorithms for auto calibration of model parameters.

"The inherent magnetic fields of common ferromagnetic objects have never before been exploited for accurate position measurements of these objects," says Rajesh Rajamani, Ph.D., of the University of Minnesota and the senior author on the paper. Previous magnetic field based sensors require use of embedded magnets and only work over small distances between sensor and magnet. The advantage of the new measurement system is that it enables non-contacting measurement of position over large separation distances and requires neither embedded components nor line-of-sight access. This means positions of pistons and other internal moving components inside engines, hydraulic cylinders, pneumatic cylinders and other industrial machinery can be measured entirely from external sensors. The researchers have also shown that the measurement system can be used on a car to measure positions of other cars in close proximity, and to thus predict an imminent collision just before the collision occurs.

A key innovation that enables the measurement system to be viable for real-world applications is the ability to automatically compensate for disturbances caused by other ferromagnetic objects. This allows the sensor system to work over larger distances between the object and sensor.