Within the heating, ventilation, and air conditioning (HVAC) mechanical rooms which support large commercial buildings, corporate campuses, institutional facilities, and industrial plants it is imperative to ensure there is a safe working environment. Strict guidelines and safety protocols must be followed in order to avoid tragic accidents which can occur as a result of failing to monitor such areas for leaking refrigerants, toxic or combustible gases.

The most common method for the prevention of such accidents is to audit HVAC mechanical room safety systems to ensure the installation of the correct gas detectors, as well as the appropriate installation location, to provide the appropriate protection. Although this ought to be done on a regular basis, it is of the utmost importance to ensure this is done whenever HVAC, boiler, electrical or fuel equipment is retrofitted or upgraded to support new functional requirements, for example those carried out to improve energy efficiency.

The safety industry has worked diligently over the past decade to improve the effectiveness of refrigerant, toxic and combustible gas sensors. Greater intelligence and communications capabilities have been added at both the sensor and systems levels due to the use of the latest digital technologies. This rapidly evolving technology has rendered the latest generation of sensors and systems more robust, less prone to false alarms and easier to both install and maintain.

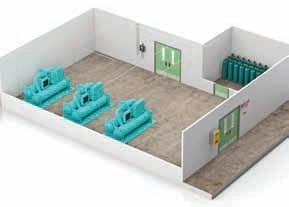

HVAC Rooms

A building’s mechanical room is the hub of its heating, ventilation, and air conditioning systems. This can include central utility plants, boiler and chiller rooms, mechanical and electrical rooms, and fuel rooms. Given the equipment housed within such rooms, there is a potential for leaks to occur. This can include the leaking of refrigerants, toxic and combustible gases which are dangerous, costly and damaging to the environment.

Figure 1. Mechanical Equipment Room Overview

Although refrigerants have a relatively low toxicity, they are still classified as a toxic gas, something that may come as a surprise for those who work with them. Despite their low toxicity, at high concentrations, refrigerants are able to displace oxygen which can, through oxygen deprivation, cause accidental injury or death by means of suffocation. Injury or death by these means are a direct violation of safety regulations under OSHA.

Moreover, these chemicals are controlled substances regulated by the U.S. Environmental Protection Agency (EPA), which means not only are they dangerous to the health and safety of workers, but they are also harmful to the environment. Many refrigerants are also classified as ozone depleting and as such are highly scrutinized. Gas detectors satisfy the requirements for equipment room emissions monitoring included in the EPA regulations.

Alongside EPA regulations, there are regulations of the American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) Standard 15, as well as any state and local building codes. The regulations under ASHAE 15 are as follows: (1) Each machinery room shall contain a detector located where a refrigerant leak would concentrate. (2) The detector shall trigger an audible and visual alarm both inside and outside the mechanical room and activate mechanical ventilation.

Detector Placement

The detectors used to monitor refrigerant leaks must not be mounted to HVAC structures which are subject to strong vibrations and shocks, such as piping. What’s more is that they must be mounted to the unit vertically. Detectors must not be placed near to excessive heat sources, direct solar heating or in a damp or wet location. It is recommended, for the sake of proper cooling, to allow at least three inches of clearance around all surfaces except the mounting surface.

Sample Point Locations

Depending on the gas monitoring system manufacturer’s recommendations, a gas sample point can be remotely located up to 150 ft (46 m) from the monitor (500 ft. [152 m] for 0.18” [4.6 mm] ID tubing) in an area where refrigerant vapors are more likely to leak or accumulate. The ability of the unit to detect leaks is greatly enhanced by placement of the sample point near to the barrel of the chiller and on the adjacent corners.

As refrigerants are heavier than air is it considered good practice to monitor locations such as pits, stair wells and trenches. If possible, monitor the vent line of the chiller. Remember to monitor the cylinder storage area if inside or near to the chiller room in case of cylinder leakage.

Choosing a Gas Monitoring System

There are several refrigerant gas detector and monitoring systems, available from multiple manufacturers, that are designed for refrigerant applications in mechanical rooms. Each of these have advantages, while many also have their own limitations. It is important to identify a list of key monitoring capabilities necessary to your own individual scenario. To aid the production of such a checklist here are some sample questions to ask suppliers:

- Does the system comply to the regulations stated under ASHRAE 15?

- What ppm level is required for the detection of gas?

- Is the system capable of multi-point monitoring and can this easily be expanded?

- Does the controller have multiple relays for fault and alarm alerts, as well as connection to a horn and strobe (required by ASHRAE 15)?

- Does the system controller include integrated BACnet or Modbus for direct digital communication to the facility’s centralized control system?

Figure 2. Refrigerant Leak Monitoring System

Prior to purchasing any detection system be sure to review the setup requirements to make sure the system includes plug-and-play capability, thus eliminating the need for time-consuming configuration tasks. It is also recommended to ask about the maintenance requirements, along with the frequency that such maintenance will be required.

Conclusion

It is imperative to adhere to safety regulations when working with refrigerants to guarantee the maintenance of a safe working environment. Refrigerants are toxic, can lead to worker accidents, injury or even death due to oxygen deprivation, are harmful to the environment and are expensive. These issues can be avoided with the newest generation of refrigerant gas monitoring systems that meet ASHRAE 15. These systems are able to rapidly detect gas, and are easy to install and use.

This information has been sourced, reviewed and adapted from materials provided by MSA - The Safety Company.

For more information on this source, please visit MSA - The Safety Company.