The water and wastewater industry offers several application possibilities for the LLT100 laser level transmitter, which simplifies the measurement.

LLT100 measuring water well level

Benefits

The LLT100 laser level transmitter offers an efficient method for measuring liquid levels in the water and wastewater (W&WW) market segment.

A complement to the ultrasonic level measurement technique, laser level offers numerous advantages:

- Narrow laser beam (<0.3° divergence) does not interfere with neighboring structures or accumulate on vessel walls

- Long range, up to 30 m (100 feet) for liquids

- Fully certified for high-risk areas

- Echo mapping not required

- No need to empty vessel or to calibrate on site

Applications

Following are the standard applications and related advantages of the LLT100 in W&WW:

Deep wastewater wet wells or sewers

- Easy to target in narrow spaces

- Laser technology is not impacted by sewer gases

- Long range enables LLT100 to be positioned at the top of the well, facilitating easy maintenance

Pumping station level measurement

- Foam will not stop the LLT100 from reading the surface; top of foam will be quantified

- Effective water level measurement even when internal structures are present

Lift station level measurement

- Dangerous area approval needed

- Consistent measurement of water combined with debris and solids

Water pond or river level

- Easily identifies running water or still water

- Dust tube employed for outdoor applications, thus shielding the instrument window from dirt

Sludge processing and monitoring

- Not affected by accumulation in the tank

- Not affected by vapors and temperature variations

- Not affected by the agitator

Benefits over Other Non-Contact Technologies

LLT100 Versus Ultrasonic

- Operates efficiently in limited spaces

- Continues reading in the presence of foam (detects the top of foam)

- Longer range

LLT100 Versus Open-Path Radar

- No need for echo mapping, easier to install

- Operates efficiently in limited spaces

- Operates efficiently in the presence of build-up

Installation Considerations

Beam Angle

On liquids, the beam angle should be perpendicular to the liquid surface, which enables measurement even when the liquid surface is still. It is always advisable to use a perpendicular beam since the liquid might get disturbed during installation but can become still after some time.

The swivel flange (A910) accessory offers a simple method to set the beam angle accurately.

Swivel flange

Condensation Prevention

Whenever possible, the heater window option must be powered. This increases the temperature of the instrument window to some extent, thereby decreasing condensation on the window surface.

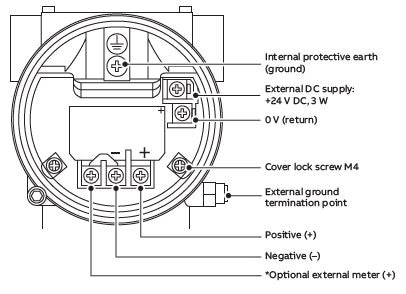

HART Terminal with Heater Option—2+2 Wires

LLT100 electrical connections

In addition, a purge ring (P910) can be used. A flow of dry air (or another gas) is truly effective at avoiding condensation.

Finally, the dust tube (P910) avoids dust, mud, or liquid splashes from soiling the LLT100 window, thus minimizing maintenance considerably.

Purge ring

LLT100 and dust tube

This information has been sourced, reviewed and adapted from materials provided by ABB Level Measurement Products.

For more information on this source, please visit ABB Level Measurement Products.