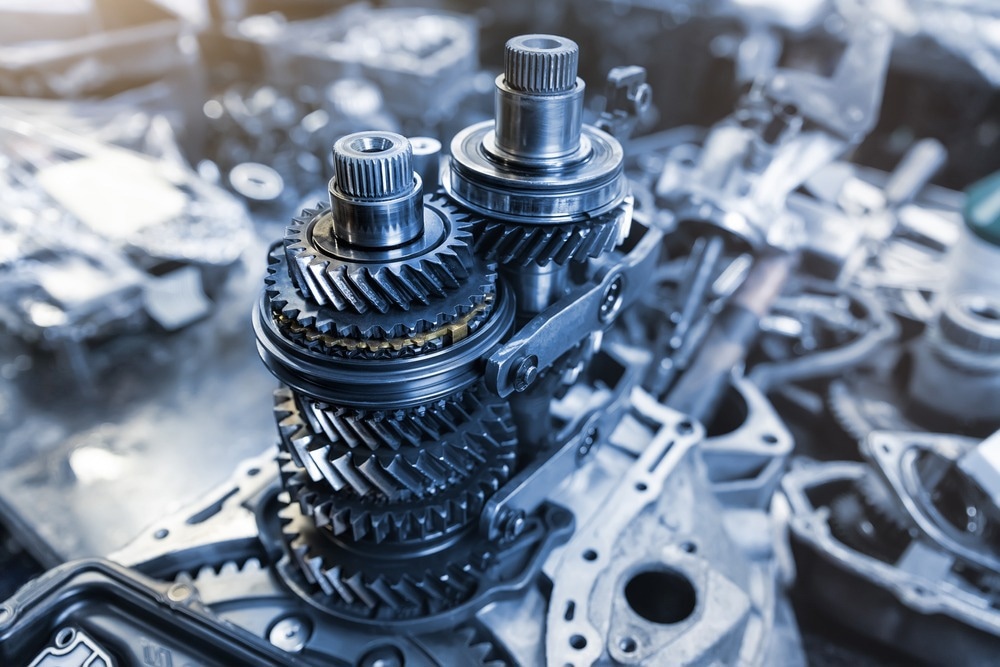

Torque sensors are devices for measuring and recording the torque on rotating systems such as gearboxes, crankshafts, rotors and engines. These are often used in industrial and technical applications to track the effectiveness of various systems, including machines, motors, and engines. This article examines the fundamentals of torque sensors, their operation, and several industrial applications.

Image Credit: dreamnikon/Shutterstock.com

What is Torque?

Torque is the measure of the twisting force applied to an object. In the same way that force accelerates an item in linear kinematics, torque accelerates an angular motion, making torque the rotational analog of linear force.

Torque is a word that may be referred to using various terms, including moment and moment of force. Lever arm distance is measured perpendicularly from the point of rotation to the line of action of the force, and force are the two inputs for torque. Torque is typically measured in pound-feet (lb-ft) or newton-meters (N-m).

Types of Torque Sensors

Torque sensors are of many types, but the most commonly used are strain gauge and magnetic torque sensors.

Strain Gauge Sensor

A strain gauge is a tool that gauges how much an object deforms under stress. In a strain gauge torque sensor, the object being measured is connected to a flexible element on which the strain gauge is mounted.

A torque applied to the object causes the flexible element to deform, changing the resistance of the strain gauge. The amount of applied torque directly correlates with the change in resistance, and a data acquisition system receives this signal for processing.

Magnetic Torque Sensor

The magnetic torque sensor is another torque sensor that measures the applied torque using a magnet and a coil. The magnet spins when a torque is exerted on the object, which shifts in the magnetic field, causing a current to flow through the coil that is proportional to the applied torque.

After that, a data collecting system receives the signal from the coil for processing.

Advantages of Torque Sensors

One of the main advantages of torque sensors is real-time monitoring of various systems, which helps optimize the system's performance and identify any potential issues before they become major problems.

Torque sensors also improve safety by monitoring multiple system components and detecting any abnormal changes that indicate any potential safety issue that can lead to a catastrophic failure.

Similarly, torque sensors help reduce costs and improve efficiency by monitoring energy-inefficient areas of the system, which eventually help to improve the system hence improving efficiency and reducing running costs over time. Moreover, the data acquired by torque sensors is valuable for research since it can provide insights into the performance and behavior of systems, helping develop new technologies and improve the existing ones.

Manufacturers of Torque Sensors

FUTEK Advanced Sensor Technology Inc. is a sensor manufacturing company that produces both rotary and reaction torque sensors of different types. Their range includes torque wrench reaction torque sensor, square drive to square drive reaction torque sensor, square drive to flange reaction torque sensor, square drive rotary torque sensor, socket extension reaction torque sensor, shaft to shaft reaction torque sensor, shaft to shaft rotary torque sensor, screwdriver reaction torque sensor, hex drive rotary torque sensor, flange to flange reaction torque sensor, and air tool reaction torque sensors.

Similarly, Althen Sensors and Controls produce rotary shaft torque sensors ranging between 0.01 nNm and 10 kNm for dynamic measuring and strain gauge-type static torque sensors for aerospace, automotive, offshore and marine applications. In addition, the company uses strain gauge and Surface Acoustic Wave (SAW) technologies for their different type of sensors.

Image Credit: Gorloff-KV/Shutterstock.com

Industrial Applications

Torque sensors are used in various industrial and engineering applications. For example, torque sensors are used in the aerospace industry to track an aircraft engine's torque aiding in performance monitoring and operational safety.

Torque sensors are used in the manufacturing sector to track the torque applied to different components during assembly. Data is then used to check that components are put together correctly and to find any errors that may have occurred during the assembly process.

Similarly, the automobile sector has one of the most widespread uses of torque sensors. The torque delivered to the wheels and the torque produced by the engine is both measured using torque sensors. The engine's performance is tracked using this data, and fuel economy is optimized.

Torque sensors are also employed in many other areas, including the medical, robotics, and renewable energy sectors. In addition, they are also used in scientific investigations, such as analyzing human motion and evaluating muscular power.

Future of Torque Sensors

With technological improvements and a rising need for accuracy and precision in industrial processes, the future of torque sensors in the industry seems bright. Due to the increasing demand for sensors that can fit in small spaces and offer precise readings, miniature torque sensors that can be incorporated into smaller gadgets and components may become more prevalent.

New materials that may be utilized to make torque sensors that are more precise and robust are being developed due to advancements in materials science. Torque sensors, for instance, are made of carbon fiber-reinforced polymer (CFRP), both lightweight and durable. Overall miniaturization, wireless connection, and sophisticated materials are anticipated to be the defining characteristics of torque sensors in the industrial future.

References and Further Reading

Kang Min, Fenglei Ni, & Hong Liu (2023) An efficient and accurate force/torque sensing method based on an excitation trajectory. Industrial Robot. https://www.emerald.com/insight/content/doi/10.1108/IR-08-2022-0206/full/html

P. H. Kim, B. D. Hauer, C. Doolin, F. Souris & J. P. Davis (2016) Approaching the standard quantum limit of mechanical torque sensing. Nature Communications. https://www.nature.com/articles/ncomms13165

Torque Sensors: Althen Sensors & Controls. (2023) Retrieved February 20, 2023, [Online] Available at: https://www.althensensors.com/sensors/torque-sensors/

Vatavuk, I., Stuhne, D., Vasiljević, G., & Kovačić, Z. (2023). Direct Drive Brush-Shaped Tool with Torque Sensing Capability for Compliant Robotic Vine Suckering. Sensors. https://www.mdpi.com/1424-8220/23/3/1195

What is a torque sensor? (2023) FUTEK Advanced Sensor Technology. Inc. Retrieved February 20, 2023, [Online] Available at: https://www.futek.com/what-is-a-torque-sensor

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.