Thermocouples improve the accuracy of differential scanning calorimetry (DSC) analysis by measuring the temperature and energy fluctuations during molecular structural transformations and phase transitions. In addition, they help assess the stability of the various materials. Here, we focus on the benefits of incorporating thermocouples into the DSC analysis of materials.

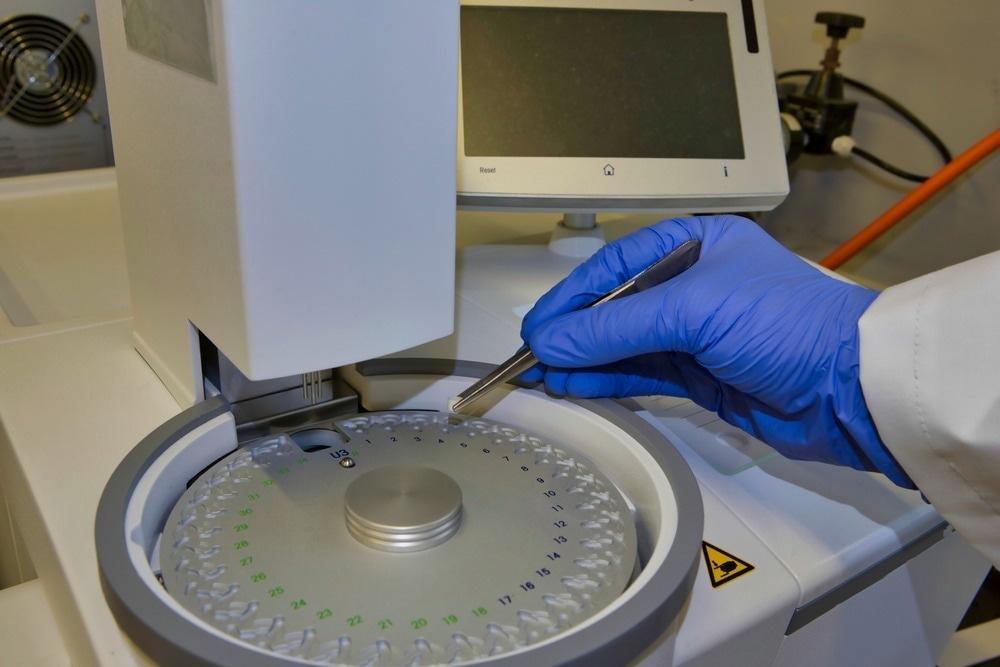

Image Credit: Matt_Turner/Shutterstock.com

Introduction to DSC

DSC is a technique used to analyze thermal properties by measuring the difference in heat flow between a substance and a reference material at varying temperatures. This technique maintains the samples and reference materials under a temperature-controlled program.

Its simple operation, high resolution, high sensitivity, good repeatability, and low sample consumption make it a desirable thermal analysis instrument in the chemical, petroleum, metallurgy, and biopharmaceutical industries.

DSC allows the measurement of several temperature-related parameters, such as the melting and crystallization points, heat of fusion, heat capacity, and thermal parameters of chemical reactions under constant heating or cooling rates.

There are two methods for DSC measurements: heat flux and power compensation. The heat flux method involves adjusting the temperature of the sample unit, which consists of both the sample and reference materials, according to a predetermined program and measuring the temperature difference between them as the temperature changes.

In contrast, the power compensation method quantifies the variation in the thermal energy applied to the sample and reference materials per unit time based on the temperature to maintain a balance. This method requires changing the temperature of the sample unit while ensuring that the temperature balance between the sample and the reference materials is preserved.

Role of Thermocouples in DSC Analysis

Thermocouples serve as temperature sensors and consist of two different metal wires connected at one end. The other end was connected to a thermocouple thermometer or a device designed to read the temperature.

Heat-flux DSC measures the temperature difference between the sample and reference while under controlled heating in a shared oven, with a thermocouple attached to the sample holder. In contrast, power-compensation DSC measurements involve using separate thermocouples and heating elements for the sample and reference, respectively, with separate currents supplied to maintain a null difference in temperature.

Principles of DSC Analysis Enhanced by Thermocouples

The DSC curve, which is derived from both heat flow and power compensation measurements, plots the rate of heat change in the sample against either time or temperature. This curve is an essential tool for quantitatively analyzing the heat change process that results from physical or chemical transformations in the sample.

The principles of the DSC analysis are enhanced by the thermocouples as follows:

- Improved Design of Temperature Difference Sensor: An article published in the Journal of Physics: Conference Series reported a new DSC design that uses multiple thermocouple series to form a radiating thermocouple stack. This stack improved the calorimetric sensitivity of the temperature difference sensor and reduced any measurement error caused by the uneven temperature distribution on the sensor.

Theoretical analysis showed that the original signal acquisition volume of the temperature difference sensor with multiple thermocouples enhanced the calorimetric sensitivity and reduced the error.

- Precision in Heat Measurement: Thermocouples help measure the differential temperatures of interest in heat-flux or power-compensation DSCs with high precision.

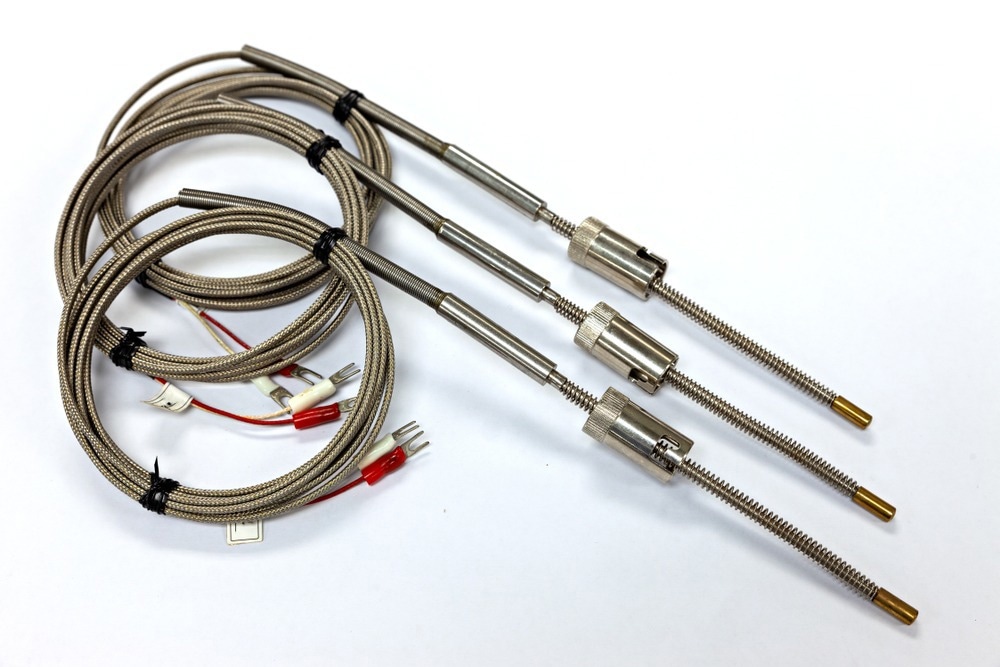

Image Credit: Meaw_stocker/Shutterstock.com

Advantages of Thermocouples in DSC Experiments

Thermocouples offer numerous advantages when used in DSC experiments, including:

- Improved thermal performance analysis of construction materials.

- Precise characterization of cure kinetics of thermosetting materials.

- Assessment of stability and folding mechanisms in proteins.

- Reproducible measurements of enthalpy during phase transitions.

- Precise thermal conductivity measurements in foods.

- High sensitivity and resolution in high-temperature measurements.

- Accurate calorimetric estimates.

- Ability to monitor and record thermal curves for a wide range of sample sizes and temperatures.

Innovations in Thermocouples - Recent Research

A study published in Materials Today Communications described the development of high-temperature irradiation-resistant thermocouples (HTIR-TCs) designed for use in Generation IV nuclear reactors to measure their internal temperature.

These thermocouples were composed of phosphorus-doped niobium (Nb-P) and lanthanum-doped molybdenum (Mo-LaO) thermoelements, protected by alumina insulation and a niobium sheath. HTIR-TCs require heat treatment at a high temperature that surpasses their maximum service temperature to establish an electromotive force (EMF) signal. However, the basis of this stabilization remains unclear.

This study examined the influence of stabilization heat treatment on the chemical stability, microstructure, and electrical properties of thermoelements to understand how stabilization of the EMF signal occurs. DSC analysis was used to evaluate the chemical stability of the Nb-P thermoelements.

The results revealed that the stabilization of the HTIR-TC EMF signal depended on establishing a diffusion interaction region at the Nb-P/alumina interface and creating Nb3P precipitates formed as a secondary phase within Nb-P during the preliminary heat treatment.

In another study published in Sustainable Energy Technologies and Assessments, researchers investigated the suitability of three-phase changing materials (PCMs) for low-temperature applications. These PCMs were incorporated into raw and expanded perlite, resulting in 12 cement-based composite mixtures, including a reference mixture.

The physical and thermal performances of the samples were monitored using thermal camera images and thermocouple measurements, as well as standard test methods for determining the physical and mechanical performances.

The results revealed that the use of lightweight aggregates, such as expanded perlite, reduced the mechanical values by up to 87%. However, this reduction was limited to 5.2% when the raw perlite was used.

Despite this limitation, PCMs showed great potential for snow-melting applications by keeping the surface warmer for longer periods. This study demonstrated the potential of using PCMs in cement-based composites for low-temperature applications, showing that they have the potential to be effective in such applications.

Conclusion

Thermocouples are essential for improving the accuracy and versatility of DSC thermal analysis techniques. They play a critical role in measuring the temperature and energy fluctuations during molecular transformations and phase transitions, providing valuable insights into material stability.

DSC, a commonly used thermal analysis technique, allows the precise measurement of various temperature-related parameters. Thermocouples, acting as temperature sensors, significantly enhance DSC analysis through their role in heat flux and power compensation.

Incorporating thermocouples into DSC experiments offers several advantages, such as reproducible measurements of enthalpy during phase transitions, precise thermal conductivity measurements in foods, and high sensitivity and resolution in high-temperature measurements.

References and Further Reading

Understanding the Importance of Thermocouples and How They Work.

Exploring Differential Scanning Calorimetry (DSC).

Zhong, X., et. al. (2020). Design of A New Differential Scanning Calorimeter. In Journal of Physics: Conference Series. 1605(1), p. 012076. Available at: https://iopscience.iop.org/article/10.1088/1742-6596/1605/1/012076/meta

Riley, S., et. al. (2023). Influence of microstructure and phase morphology on the stability of high-temperature irradiation resistant thermocouples. Materials Today Communications, 35, p. 105972. doi.org/10.1016/j.mtcomm.2023.105972

Şahin, Y., & Gündüz, Y. (2024). PCMs with perlite aggregate for snow melting applications. Sustainable Energy Technologies and Assessments, 62, p. 103617. doi.org/10.1016/j.seta.2024.103617

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.