Stringent control of stocks based on various factors, including quantity, pile shape, and storage time, is necessary. ABB offers a host of volumetric scanners and laser level transmitters that yield rapid, accurate and reliable solutions for stock management.

Factors Influencing Stock Management

In sugar production, storage time is directly connected to loss of sugar in raw material as a result of deterioration. Fresh cut sugar cane needs to be supplied to sugar mill quickly. The same is applicable for sugar beet unless they are frozen.

Nonetheless, each pile must be rigorously tracked because time is crucial especially in the harvesting season during which sugar mills are operated around-the-clock. Pile size and shape is indispensible to optimize the drying speed of bagasse employed as fuel for the sugar mill.

Very large stockpiles of bagasse need to comply with regulations, thus demanding a management system to reduce their environmental impact. It is also possible to optimize the shape of sugar beet piles to accelerate freezing.

Quantity is the fundamental aspect of any inventory management and control techniques, where sugar holdings need to be reduced while maintaining a consistent and effective flow. Optimizing inventory can be achieved through many aspects such as timely stock management, stockpile size, stock level fluctuation, and stockpile turnover period.

Considering the energy costs and sugar price fluctuations all across the world, even the smallest improvement is of great benefit for any manufacturer. Moreover, the constantly increasing sugar demand is the compelling factor for sugar producers to be more efficient.

Sugar Production Process

Several intermediate products are generated along the sugar production process. Raw sugar production in cane sugar mills is rapid and the sugar is kept in large warehouses prior to being supplied to sugar refineries.

After the filtration and evaporation processes, the ensuing thickened sugar juice is held in storage tanks before being converted to the final, refined granulated sugar. The granulated sugar is typically kept in storage bins before packaging or bulk load out. During the year, the stock level will gradually reduce as the sugar is sold to industries, shops and on export.

Several other materials are required in sugar production, which also generates by-products that need to be managed in the same way as sugar products. A by-product of sugar cane is bagasse, which is basically crushed sugar cane. Beet pulp is a by-product of sugar beet and is a compressed and dried paste left after the extraction of most of the sugar content from the beets.

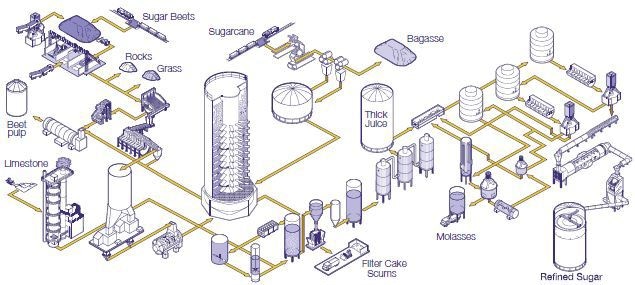

The coloring compounds and impurities in sugar juice are removed by milk-of-lime produced by heating limestone in a lime kiln. This results in a filter cake that is used as an energy source with bagasse or sold as a fertilizer. Purification can also be performed using activated carbon or bone char. The typical sugar production process is illustrated in Figure 1.

Figure 1. Typical sugar production process

ABB Level Products in Sugar Production

It is easier to install ABB laser level transmitters in storage bins such as silos for continuous monitoring of material quantity. A signal output can be transmitted to the controlling systems to trigger actions through relays.

ABB laser volumetric scanners can be mounted on silos, domes, warehouses, stockyards, or large storage bins for accurate quantification of sugar volume in sight, either for contained areas like small bunkers or large stockpiles. Irregular shapes or interfering infrastructures are handled through a service of data treatment, which yields reliable data in a timely manner.

Robust construction, non-contact pulsed laser technique, multi-mounting options, low beam divergence, narrow beam, non-condensing optics (heated lens) are the key features of ABB laser products.

These devices are immune to solids size, angle of response, the dielectric constant of the material, moving and falling material, vibrations at surfaces, condensation, gas and high humidity, and vessel construction. The ability to measure great distances, high accuracy to get around infrastructures, and easy installation are the other benefits of ABB laser products.

ABB VM3D is recommended to deal with sugar stockpiles (Figure 2), where the challenges involved are dusty environment, warehouse structures and very large stockpiles. It replaces manual survey operation through accurate inventory management system and facilitates precise inventory control for production process on a daily basis. In addition, correlated quantity is paid for delivered material.

Figure 2. Sugar pile

Besides providing guaranteed data, ABB VM3D eliminates artifacts and infrastructures. High accuracy, remote monitoring, data processing services, multiple scanners network and ABB high performance engineering are the other key features of ABB VM3D.

LM80/LM200 Laser Level Transmitters have fast electronics and 4-20mA current loop and relays. They are configurable devices with no moving parts. Zero maintenance, rapid response, user friendliness, easy to install are the key benefits of LM80/LM200 Laser Level Transmitters.

ABB LM200 is recommended in sugar silos (Figure 3), where the challenges involved are extreme peaking and slumping of the material, falling stream of sugar, simultaneous filling/reclaiming (rat-holing), and near empty levels on narrow bottom. Goals achieved with ABB LM200 include reliable results, constant and accurate readings, and zero-maintenance transmitter.

Figure 3. Sugar refinery silos

About ABB Level Measurement Products

ABB is a leader in power and automation technologies that enable utility and industry customers to improve performance while lowering environmental impact. The ABB Group of companies operates in around 100 countries and employs about 150,000 people.

ABB Level Measurement Products is a leading manufacturer of state-of-the-art level and volume instrumentation for liquid and bulk solids detection. ABB products have demonstrated versatility in numerous applications, affording our customers a variety of practical and innovative solutions for their installation needs.

Our company designs, manufactures, and markets rugged, accurate and reliable equipment addressing numerous applications such as: mining and construction, aggregates, fertilizers, chemical processing, power generation, food and beverage, pulp and paper processing, upstream oil & gas, and downstream oil & gas.

Specifically, the ABB family of non-contact laser level and volume products (LM80, LM200 and VM3D) as well as ultrasonic transmitters, Rf, tuning fork and paddle wheel switches, provide solutions for accurate measurement in the following applications: inventory in bunkers, blending hoppers, reactor vessels, level control, volumetric measurement, and various dry bulk solids and opaque liquids in silos.

This information has been sourced, reviewed and adapted from materials provided by ABB Level Measurement Products.

For more information on this source, please visit ABB Level Measurement Products.