The LLT100 is designed specifically for industrial applications and harsh environments, providing continuous, non-contact level measurement capabilities for inventory management and process automation. Building on the proven track record of the ABB laser level transmitters, the LLT100 has the ability to provide reliable level measurements of any liquid, even transparent, clear liquids.

Key Features of LLT100

The following are the key features of the LLT100:

Detect any liquid

The LLT100 can detect any liquid, including turbulent, agitated liquids and liquids of any color - even transparent liquids. It is independent of presence of gases or independent of material properties.

Easy setup

The LLT100 features a swivel mounting flange for easy beam alignment. It reads signal amplitude from display to deliver optimized performance and computes volume with linearization table.

Liquid Detection

Using laser time of flight, the LLT100 carries out level measurements for solids or liquids. Measuring clear, transparent liquids is often a limitation of laser level measurement products. However, the LLT100 overcomes this limitation with the use of improved laser pulse control, powerful algorithms, and detection performance, providing reliable level measurements for any liquid. It is approved for use in explosive atmospheres, and pressure rated models of the LLT100 are also available.

New Applications

With new capabilities, the LLT100 paves the way for a wide range of new applications:

- Water and waste water processing plants

- Oils and hydrocarbons

- Liquids in food and beverages

- Chemical tanks

- Liquids in any industry, including metals, mining, power, pulp and paper, and pharmaceuticals

Clear Water Level Measurement

The LLT100 was extensively tested to measure clear liquids in a number of different conditions. It delivered a good performance for all tested liquids, from transparent ones such as transparent mineral oil or pure water to colored liquids.

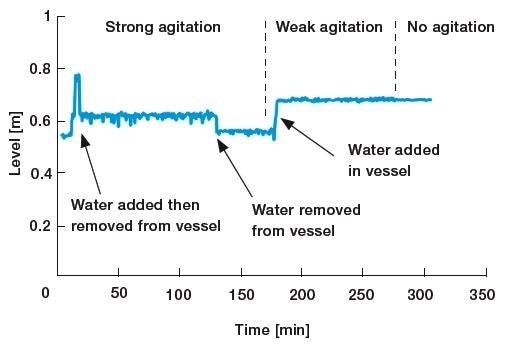

It can provide reliable measurements at distances up to 30 m and monitors the liquid surface level even when waves and surface agitation are present. In the below figure, waves are formed in a clear water tank. Fast changes can be noticed as there is no damping.

As can be observed, the LLT100 can detect the surface even in the presence of strong agitation. The standard deviation of the measured level is ± 1 mm in the absence of agitation as can be seen on the right of the plot, highlighting the resolution and repeatability of the measurement.

The LLT100 returns the level of the top of the foam when dense foam is present, but provides reliable measurements as it is not confused by the foam.

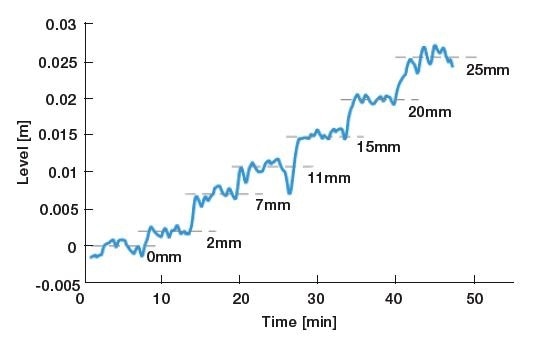

Tracking Small Level Changes

This experiment involves filling a clear water tank with very small increments on the order of a few millimeters. As can be observed, even very small level changes can be observed. Here, the changes of the order of 5 mm and down to 2 mm can be observed with the LLT100. Variations are mainly due to agitation during filling the vessel.

Water Treatment Plant

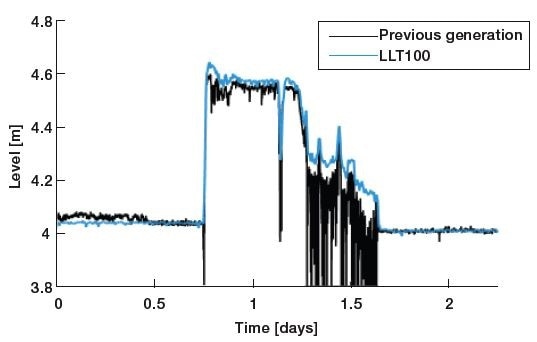

LLT100 units were installed in various water treatment plants in Quebec City, Canada. They have been delivering great performance for the several months, and a significant improvement has been observed compared to the earlier generation of the product.

They deliver reliable results even over water agitation, level fluctuations, and ambient temperature changes. Plots of the level recorded over time reveal the superiority of the LLT100 over previous generation when clear liquids are measured.

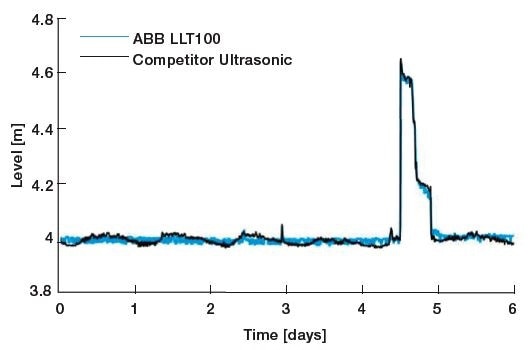

In addition, the LLT100 was also installed alongside a competitor’s ultrasonic sensor for reference. From the results, it can be observed that the LLT100 output remains unaffected by the daily temperature changes, showing a straight LLT100 line when no filling occurs. Conversely, a daily oscillation is observed in the case of the competitor’s product line.

Considerations for Liquid Application

Product Configuration

The LLT100 is available with a range of accessories for liquid applications:

- Swivel flange - Recommended to precisely align the laser beam perpendicular to the liquid surface

- Heated window - Recommended in all areas where condensation can occur on the transmitter window

- Dust tube - Recommended in applications where liquid splashing on the window can occur, limiting maintenance and increasing reliability

Installation

The beam must be carefully aligned as perpendicular as possible to the surface of the liquid when measurements are performed on liquids. The beam must be aimed within ±5° of the vertical for liquid applications, but can be aimed at virtually any incident angle to the surface for solid applications.

This can be easily performed by reading the signal amplitude on the embedded display. In a typical setup, the LLT100 is positioned on the swivel flange, and the user adjusts the flange angle to monitor the signal amplitude. The beam is at right angles to the surface when the signal amplitude is maximized.

Software Configuration

The following settings are recommended when the LLT100 software is configured for liquid applications:

- Enable both empty and fill rates filters and set them to realistic values

- Use the Clear liquid measurement mode

- Limit the effect of surface agitation using a median filter

This information has been sourced, reviewed and adapted from materials provided by ABB Level Measurement Products.

For more information on this source, please visit ABB Level Measurement Products.