The LLT100 laser level transmitter is specifically made for harsh environments and industrial applications. For inventory management and process automation, the transmitter provides continuous, non-contact level measurements. The oil and gas industry can benefit significantly from the distinct capabilities of laser level measurement when these capabilities are tailored for industrial applications.

High Reliability

- Nearby structures, local changes, and buildup on vessel walls do not affect the tightly focused laser beam

- Even if the dielectric constant of a solid or liquid is low, they can be detected without recalibration

Easy Setup

- Quick on-site setup, with no requirement for local calibration or echo mapping

- Flexible installation; device can be proximal to wall or aimed at solids at an angle

ABB Solutions

ABB has more than 35 years of experience in oil and gas production level instrumentation and solving the most challenging level measurement applications. LLT100 employs laser time-of-flight to measure levels of liquids or solids. The LLT100 can provide reliable measurements for any liquid, including transparent liquids, by using efficient pulse detection, advanced laser pulse control, and powerful algorithms. The LLT100 is also available in pressure-rated models. It is approved for use in explosive work environments, and is powered from the 2-wire current loop, making this instrument very relevant to the oil and gas industry.

Typical Applications

LLT100 is employed in the following applications:

- API separators

- Storage tanks for water, oils, and drilling mud

- Floating roof level measurement

- Positioning and collision avoidance in offshore platforms

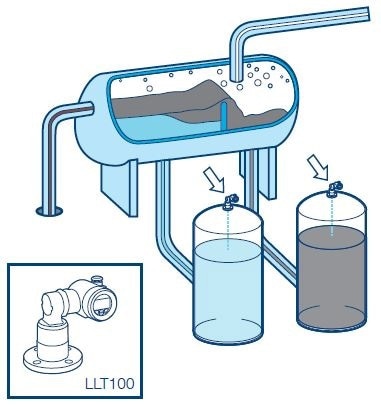

API Separators

Separation of oil and suspended solids from wastewater effluents in a refinery can be accomplished using API oil-water separators. Subsequently, oil and water are stored in monitored tanks.

Measurements of oil and water levels in storage tanks can be carried out using LLT100 in API separators. The dielectric constant of the material does not affect the measurements, and the LLT100 is immune to water droplets on its window. Simple, reliable, non-contact level measurements can be obtained.

The LLT100 is also available with a heated window which raises the window temperature beyond ambient levels, preventing condensation on the window surface.

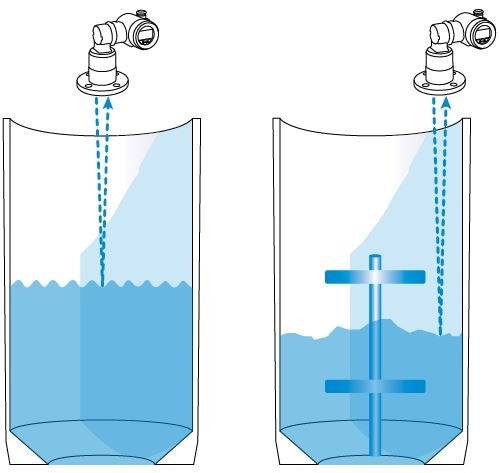

Storage Tanks

All types of tanks require monitoring. A variety of materials can be stored in the tanks.

Any liquid can be efficiently measured by laser level measurements. Accuracy is not affected and recalibration is not required for LLT100, even when the liquid in the tank is changed.

The narrow laser beam has a <0.3° beam divergence, and allows LLT100 to take measurements even in tight spaces, such as a 5 cm (2 inches) diameter pipe over 5 m (15 feet) in length. When a tank contains an agitator, it is possible to shoot the laser beam between the edge of the agitator and the tank wall. In this case, the agitator does not affect the measurements. Filtering functions can be employed to reliably track the real liquid surface when it is necessary to shoot the laser beam in the path of an agitator.

Finally, the LLT100 allows accurate laser level measurement of all liquids, opening up a vast array of possibilities.

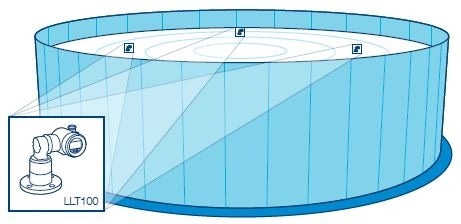

Floating Roofs

The height of a floating roof can be reliably measured by using LLT100. If necessary, the transmitter can be placed in close proximity to the wall. Local structures do not affect the measurements, since the instrument’s beam is narrow. This enables reliable measurements that do not have to be reconfigured over time.

Using several units of the LLT100, the roof angle can also be measured. Several units of the transmitter can be safely employed on the same site, as the units do not interfere with each other and special settings are not required.

As rain or snow does not affect LLT100, it can be used inside or outside. During external use, the dust tube protects the transmitter from the environment, minimizing the need for maintenance.

Floating roof measurements can be easily taken using LLT100.

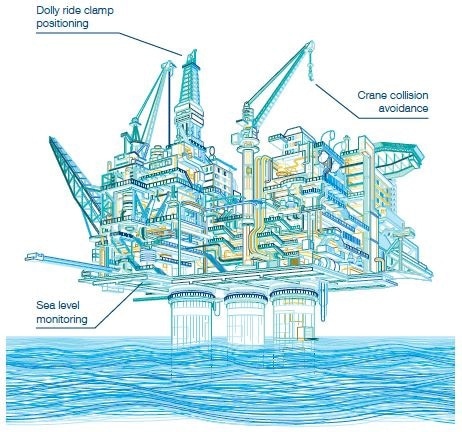

Offshore Applications

A number of applications on offshore platforms can be performed using the ABB laser level measurement line of products.

Sea Level Monitoring

Even in agitated waters, laser level measurement provides reliable measurements. The sea level under the platform can be easily measured, thanks to the fast rate of measurement and the ability to measure fast step changes.

Precise Positioning

ABB laser level measurement products are particularly designed for harsh industrial environments, making them ideal for offshore applications. Precise distance measurement of moving objects, such as drilling pipe handling equipment, can be achieved by the laser level measurement products.

When compared to using frequently damaged mechanical devices such as limit switches, maintenance costs are reduced when laser measurements are employed for positioning purposes. In addition, service lifetimes for laser level measurement products are prolonged since they can be placed away from moving objects.

Collision Avoidance

Laser level measurement can be employed to avoid crane collisions, by measuring the distance to nearby objects to automate safety procedures.

This information has been sourced, reviewed and adapted from materials provided by ABB Level Measurement Products.

For more information on this source, please visit ABB Level Measurement Products.